Drilling stabilizers play a vital role in maintaining wellbore stability and ensuring precise drilling operations. These essential tools reduce vibration, prevent deviation, and extend the life of drill bits. Understanding their design, function, and types helps drillers achieve smoother, safer, and more efficient drilling performance in various applications.

Selecting the right drilling stabilizer is crucial for optimal results. With different types available—such as integral blade, welded blade, and replaceable sleeve stabilizers—each serves a specific purpose based on wellbore conditions. This guide explores how drilling stabilizers work, their benefits, and tips for choosing the best type for your project.

What is a Drilling Stabilizer?

A drilling stabilizer is a vital downhole tool used in oil, gas, mining, and geothermal drilling to maintain wellbore stability and control the drill string’s direction.

It reduces vibration, prevents borehole deviation, and minimizes wear on drilling components, ensuring smoother, safer, and more efficient drilling operations with extended tool life.

Drilling Stabilizer Components

Drilling stabilizers are composed of several key components that work together to ensure stability, control, and efficiency during drilling operations. Each part plays an important role in maintaining proper alignment, reducing vibration, and enhancing the overall performance of the drilling assembly in demanding oil, gas, and mining environments.

- Body: The main structure of the stabilizer, typically made from high-strength alloy steel, provides the foundation for the blades and connections. It withstands extreme pressure and torque, ensuring stability, durability, and resistance to wear during drilling in harsh geological formations.

- Blades: Attached to or integrated with the stabilizer body, blades maintain contact with the borehole wall. They reduce vibration, control deviation, and provide precise directional guidance. Blade shape, size, and angle can be customized for specific drilling conditions to enhance stability and performance.

- Connections: The threaded connections link the stabilizer to other parts of the drill string. Properly designed connections ensure secure attachment, minimize operational risks, and allow quick installation or removal. Different thread types are available to match various drilling requirements and equipment setups.

- Surface Treatment: The stabilizer’s surface often undergoes treatments such as hardfacing, coating, or heat treatment to enhance wear resistance and durability. These treatments protect against abrasion, corrosion, and mechanical stress, ensuring the stabilizer performs efficiently and maintains a long service life.

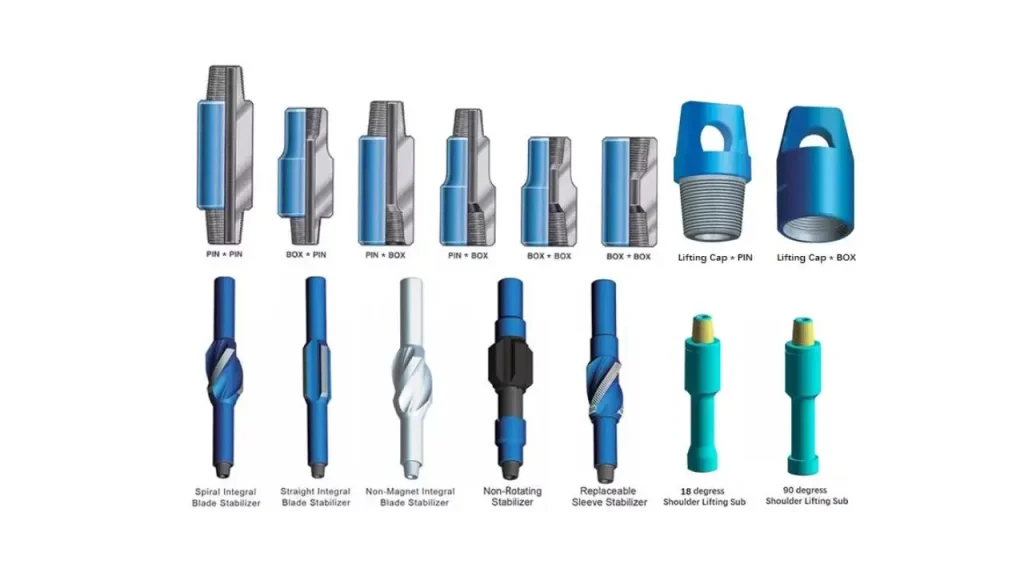

Drilling Stabilizer Types

Drilling stabilizers come in different types, each designed to meet specific drilling conditions and performance needs. Choosing the right stabilizer type ensures better wellbore stability, reduced vibration, and extended tool life. Understanding these types helps drillers select the most suitable option for safe, efficient, and cost-effective operations.

- Integral Blade Stabilizer: Machined from a single piece of high-strength steel, this stabilizer offers maximum durability and strength. It eliminates weak points from welds, providing consistent performance in harsh drilling environments. Ideal for deep or directional wells, it ensures superior stability and extended tool life.

- Welded Blade Stabilizer: This type features blades welded onto a solid body, offering reliable performance at a lower cost. It provides good wellbore contact and vibration control, making it suitable for general drilling operations. The welded design allows flexible customization for various drilling conditions.

- Replaceable Sleeve Stabilizer: Designed for easy maintenance, this stabilizer has removable sleeves or blades that can be replaced when worn. It reduces downtime, extends the tool’s lifespan, and enhances cost efficiency. Perfect for operations requiring frequent tool adjustments or maintenance flexibility.

- Non-Magnetic Stabilizer: Made from non-magnetic materials, this stabilizer is used in directional and measurement-while-drilling (MWD) applications. It prevents magnetic interference, ensures accurate tool readings, and provides stability in sensitive drilling environments, maintaining precision and reliability throughout the drilling process.

String Stabilizer Drilling

String stabilizers are critical components in drilling assemblies, designed to maintain drill string alignment, reduce vibration, and enhance wellbore stability. Proper use of string stabilizers ensures smoother operations, extends tool life, and improves drilling accuracy. Understanding their benefits and applications helps optimize drilling performance in oil, gas, mining, and geothermal projects.

- Reduce Drill String Vibration: String stabilizers minimize lateral and torsional vibrations along the drill string. By reducing oscillations, they prevent excessive wear on drill components, maintain stable drilling conditions, and improve directional control, leading to safer, more efficient, and cost-effective drilling operations.

- Enhance Wellbore Stability: Stabilizers support the drill string within the borehole, maintaining proper alignment and preventing deviation. They help avoid doglegs or unwanted borehole curvature, ensuring consistent hole quality and reducing the risk of stuck or damaged tools.

- Improve Drilling Efficiency: By maintaining steady contact with the borehole wall, string stabilizers optimize weight distribution and torque transmission. This results in faster penetration rates, reduced bit wear, and more efficient energy transfer during drilling operations.

- Extend Tool Life: Stabilizers reduce stress on drill string components by controlling vibration and stabilizing the assembly. This prolongs the lifespan of bits, collars, and other downhole tools, lowering maintenance costs and minimizing downtime on demanding drilling projects.

How to Choose Suitable Drilling Stabilizers?

Choosing suitable drilling stabilizers is essential for achieving efficient, safe, and cost-effective drilling operations. The right stabilizer improves wellbore stability, reduces vibration, and enhances tool life. By considering factors such as formation type, drilling depth, and operating conditions, you can ensure optimal drilling performance and reliable results.

- Assess Formation Conditions: Evaluate the geological formation, hardness, and abrasiveness before selecting a stabilizer. Choosing the right blade type and material ensures better wear resistance, stable drilling, and minimal deviation, allowing consistent performance across different rock layers and drilling environments.

- Determine Borehole Size and Trajectory: Select a stabilizer that matches your borehole diameter and planned well path. Proper sizing improves contact between blades and borehole walls, reduces lateral movement, and helps maintain directional accuracy throughout the drilling process.

- Consider Drilling Type and Application: Identify whether your project involves vertical, directional, or horizontal drilling. Each drilling type requires specific stabilizer designs to achieve balance, reduce vibration, and enhance control, ensuring optimal performance and safety under varying operational conditions.

- Check Connection and Compatibility: Ensure the stabilizer’s connections are compatible with your drill string. Proper thread matching guarantees safe installation, prevents tool failure, and facilitates easy assembly or disassembly, reducing downtime and improving operational efficiency during drilling operations.

- Focus on Material and Durability: Choose stabilizers made from high-strength or non-magnetic alloys for better wear resistance and corrosion protection. Durable materials extend tool life, reduce maintenance needs, and ensure dependable performance even in the most demanding drilling environments.

Conclusion

Drilling stabilizers are indispensable tools for modern drilling operations, ensuring accurate borehole trajectories and reducing equipment wear. By maintaining stability and minimizing vibration, they contribute to improved drilling efficiency, reduced downtime, and longer tool life in oil, gas, mining, and geothermal applications.

Choosing the right stabilizer depends on understanding your drilling environment and performance needs. Whether you require an integral blade, welded blade, or replaceable sleeve design, the proper selection enhances stability, improves safety, and ensures cost-effective drilling operations over time.

For durable, high-performance drilling stabilizers, trust Sinodrills. We offer wholesale stabilizers engineered for reliability, precision, and longevity. With advanced manufacturing, strict quality control, and customizable options, Sinodrills delivers the ideal solutions to meet your drilling challenges and boost overall project performance.