The unsung hero of many deep rock drilling operations is a small, internal component: the foot valve, often called a blow tube. This crucial part is indispensable in Down-The-Hole (DTH) hammer systems, particularly for older or specialized valved hammers. Understanding its function is key to mastering efficient drilling.

Its primary role is to manage the flow of compressed air, the driving force of the hammer. Crucially, the foot valve prevents water and rock cuttings from entering the hammer’s main chamber, protecting the piston and ensuring the drill maintains its powerful impact energy, especially in wet conditions.

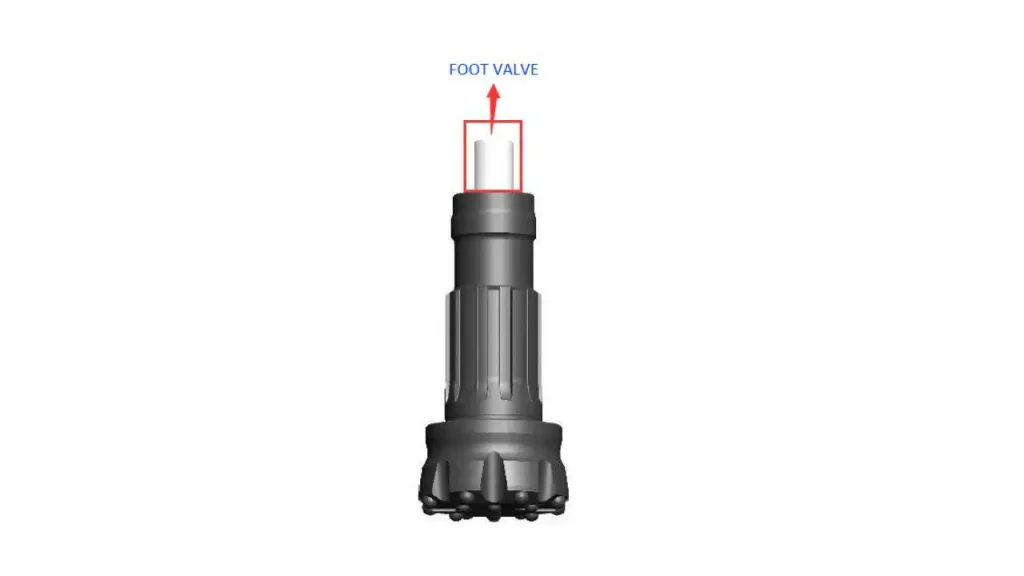

What is a Foot Valve for Drill Bits?

The foot valve, often referred to as a blow tube or exhaust tube, is a small, typically plastic component seated within the back of a Down-The-Hole (DTH) hammer drill bit. It is a critical part of the older, “valved” style of DTH hammers, although it is eliminated in most modern, “valveless” hammer designs. Its position and design are crucial for the hammer’s operation, as it directly relates to the efficient use and control of the high-pressure compressed air that powers the percussive action.

The primary function of the foot valve is threefold: air regulation, pressure conservation, and contamination prevention. It works to direct the compressed air flow inside the hammer’s main chamber, ensuring the piston cycles correctly and delivers maximum impact energy to the bit. More importantly, when drilling in wet formations or where there is high back pressure, the valve acts as a non-return component, preventing water, cuttings, and rock debris from surging back into the hammer mechanism and causing damage or operational failure.

What is the Foot Valve Made of?

The Down-The-Hole (DTH) foot valve, often called a blow tube or exhaust tube, is a small, critical component fitted inside the drill bit shank of older, valved hammers. Since it is subjected to intense pressure, impact, and heat, its material must be durable yet easy to manufacture. This component is generally made from two main types of materials:

Hardened Plastic or Specialized Rubber Polymers

- This is the most common material for modern foot valves due to its low cost and ease of molding to precise specifications. However, plastic is susceptible to thermal damage from drilling heat and fracture from rock cuttings, making it a common failure point that requires frequent replacement.

High-Strength Alloy Steel

- Some heavy-duty or older, non-replaceable foot valve components within the DTH hammer assembly itself are machined from heat-treated alloy steel. Steel provides superior resistance to impact and abrasion but adds to the overall cost and complexity of the valved hammer’s maintenance and manufacturing process.

Drill Bits with Foot Valve

Drill bits that utilize a foot valve are integral to older Down-The-Hole (DTH) percussion drilling systems. This component, also known as a blow tube or exhaust tube, is fitted inside the drill bit shank and is essential for the hammer’s mechanics, primarily regulating air flow and protecting internal parts from contamination.

Here’s the foot valve’s key functions in these drilling tools:

- Airflow Direction and Efficiency: It precisely controls the release of compressed air from the hammer. This mechanism is critical for ensuring the piston cycles correctly, maximizing the force and frequency of impacts to the rock face, and ultimately improving penetration rates.

- Maintaining Internal Pressure: The valve helps to retain the necessary pneumatic pressure within the hammer’s cylinder. Conserving pressure is vital for the piston’s powerful reciprocation and helps prevent premature wear and damage to the delicate internal components of the DTH hammer.

- Preventing Contamination: In wet or fractured ground, the foot valve acts as a non-return barrier. It stops water, mud, and fine rock cuttings from traveling back up into the DTH hammer’s internal mechanism, which could lead to immediate jamming or severe long-term corrosion.

Drill Bits without Foot Valve

Modern advancements in Down-The-Hole (DTH) technology have led to a revolutionary design: the valveless hammer system, which operates with drill bits that do not require a foot valve. This innovation was introduced to overcome the common failure points and limitations of older, valved hammer designs, boosting overall drilling productivity.

The benefits of eliminating the foot valve include:

- Higher Penetration Rate: Valveless hammers allow for simpler air distribution and more efficient energy transfer, resulting in faster and more powerful impacts. This optimized airflow bypasses the restriction caused by the valve, significantly increasing the drilling speed in hard rock formations.

- Reduced Failure and Downtime: The plastic foot valve is a common breaking point, easily damaged by heat, expansion, or physical impact from cuttings. Removing this fragile component improves hammer reliability, reduces the need for constant maintenance, and minimizes non-productive time on-site.

- Lower Air Consumption: By simplifying the internal mechanism and air circuit, valveless designs utilize the compressed air more effectively. This leads to a lower operational air requirement and better fuel efficiency for the compressor, offering notable cost savings over the lifespan of the equipment.

Differences Between Drill Bits with Foot Valve and Without Foot Valve

The difference between Down-The-Hole (DTH) drill bits with a foot valve and those without stems from the design of the DTH hammer itself. The transition from older, valved hammers to modern, valveless hammers marks a significant evolution in drilling efficiency and reliability by simplifying the air distribution system.

Air Distribution Mechanism

In DTH systems that utilize a foot valve (valved hammers), the foot valve (or blow tube) sits at the base of the hammer and acts as a mechanical component to regulate the flow of compressed air. This valve plate controls the cyclical movement of the piston by directing air pressure into different chambers.

Valveless systems, which use bits without a foot valve, eliminate this external mechanical component. Instead, the air distribution is controlled entirely by the piston’s movement and ports machined directly into the internal cylinder. The piston’s reciprocating motion automatically opens and closes air passages, streamlining the entire air-cycle.

Impact Frequency and Energy

Hammers that use a foot valve generally feature a heavier, shorter piston with a longer stroke. This configuration delivers a higher impact energy per blow, but at a relatively lower frequency, making them historically suited for very hard, deep rock formations.

Conversely, valveless hammers are designed with a lighter, longer piston and a shorter stroke. This allows the piston to reciprocate much faster, generating a significantly higher impact frequency. While the energy per blow might be slightly less, the rapid succession of impacts often results in a faster overall penetration rate.

Penetration Rate (ROP)

Due to the streamlined air path and higher impact frequency, DTH bits without a foot valve generally achieve a 15% to 30% faster rate of penetration (ROP) than their valved counterparts under similar conditions. This optimized airflow bypasses the restriction caused by the valve, minimizing wasted energy.

The inclusion of a foot valve, while necessary for the older hammer design, introduces a slight aerodynamic restriction. This, combined with the lower frequency of the hammer cycle, typically translates to a slower overall drilling speed compared to the highly optimized valveless systems.

System Reliability and Maintenance

The foot valve is often made of plastic or a similar material and is a common wear point and failure risk. It is susceptible to damage from heat, thermal expansion, and impact from rock cuttings, which leads to increased downtime and a higher cost for consumable replacement parts.

Valveless bits significantly improve system reliability by removing this fragile component. The hammer’s simplified internal structure, featuring fewer internal parts, results in a lower overall failure rate, less frequent need for maintenance, and a reduction in non-productive time on the drill site.

Air Consumption and Cost Efficiency

Hammers requiring a foot valve are sometimes considered less air-efficient because the valved air distribution system is not as optimized as modern designs. The mechanism often exhausts a portion of the compressed air’s energy, which can slightly increase the necessary air volume and consequently, fuel consumption.

Bits used in valveless hammers are associated with lower overall air and fuel consumption. The highly efficient, pressure-optimized air cycle in valveless hammers maximizes the expansion energy of the compressed air, leading to notable fuel savings and lower running costs over an extended drilling operation.

| Feature | Drill Bits WITH Foot Valve (Valved Hammers) | Drill Bits WITHOUT Foot Valve (Valveless Hammers) |

| Air Distribution | Regulated by a physical valve plate in the bit’s shank. | Regulated by the piston’s movement and ports in the hammer body. |

| Impact Frequency | Lower frequency, longer stroke. | Higher frequency, shorter stroke. |

| Penetration Rate (ROP) | Slower due to air restriction and lower frequency. | Faster (often 15-30% higher) due to optimized air cycle. |

| Reliability | Lower, as the plastic valve is a fragile, high-wear component. | Higher, due to simpler internal structure and fewer failure points. |

| Air Efficiency | Lower efficiency; higher air and fuel consumption. | Higher efficiency; lower air and fuel consumption. |

| Piston Type | Heavier, shorter piston. | Lighter, longer piston. |

How to Choose Foot Valve Drill Bits?

When selecting DTH drill bits that incorporate a foot valve, it is essential to consider several key factors to ensure optimal performance and compatibility with your existing drilling equipment. The correct foot valve and bit combination is crucial for maintaining hammer efficiency and minimizing costly wear.

To make the right choice, focus on these critical aspects:

- Shank Type and Compatibility: The foot valve and bit shank must perfectly match your specific DTH hammer model (e.g., DHD, COP, QL). Mismatching components can lead to poor energy transfer, rapid tool wear, and the potential for severe hammer damage, voiding warranties.

- Drilling Conditions and Rock Type: For extremely wet holes, the valve’s sealing capability is vital to prevent water intrusion into the hammer chamber. Choose robust valve materials suitable for the specific abrasiveness and fractured nature of the rock formation you are targeting.

- Valve Material and Durability: Foot valves are typically made from hardened plastic or specialized rubber polymers. Evaluate the material’s resistance to thermal stress and impact shock, as a broken valve causes immediate air loss and system failure, demanding frequent replacement in harsh environments.

- Bit Face Design (Concave/Flat): While not strictly the valve, the bit’s face design must complement the valve’s presence. Valved systems often pair with concave faces for better hole stability, ensuring the valve’s protrusion does not negatively affect the initial drilling start-up.

Conclusion

The foot valve in a DTH hammer bit is more than just a small plastic component; it is vital for controlling air distribution, maximizing impact energy, and preventing system contamination. Its presence allows drillers to maintain high penetration rates and ensure the longevity of their valuable down-the-hole equipment, particularly when encountering water or fractured ground.

A correctly functioning foot valve minimizes downtime and costly repairs by keeping the hammer clean and dry, securing continuous, reliable performance. This simple mechanism is a testament to the engineering that makes DTH drilling the method of choice for challenging applications like water well and deep-hole mining projects globally.

For superior drilling efficiency and tool life, it is crucial to use high-quality components. You can get wholesale drill bits with foot valves for your valved DTH hammers directly from our reliable inventory at Sinodrills. Trust our durable, precision-engineered tools to deliver consistent, powerful results on your next drilling job.