A hole opener is an essential tool in the drilling industry, designed to enlarge a pre-drilled pilot hole to a larger diameter. This process, known as “hole opening” or “reaming,” is crucial for various applications, including oil and gas drilling, trenchless technology, and mining. Understanding the function and components of a hole opener is key to successful drilling operations.

This comprehensive guide provides an in-depth overview of hole openers, including their types, applications, and best practices for use. We’ll delve into the different components of a hole opener, such as the body, cutters, and jet nozzles, and explain how each part contributes to its efficiency and performance.

What is Hole Opener?

A hole opener, also known as a reamer, is a specialized drilling tool used to enlarge a pre-drilled pilot hole to a larger diameter. It is commonly employed in various industries, including oil and gas, mining, and horizontal directional drilling (HDD).

The tool consists of a body with multiple cutters or reaming heads attached. As the hole opener rotates and is pushed forward, the cutters scrape and break away the rock or soil from the walls of the pilot hole, expanding its size to the desired diameter. This process is highly efficient and allows for the creation of large-diameter boreholes without the need for a larger, more powerful rig for the initial drilling phase.

Open Hole Drilling Method

The open-hole drilling method is a technique used to create a borehole without installing casing or a liner in the rock formation. The borehole remains “open” to the surrounding formation, allowing for direct interaction between the drilling fluid and the rock.

This drilling method is often used in stable, competent rock formations that can withstand the pressure and stress of drilling without caving in. It is common in mining, geothermal, and some oil and gas applications where the geological conditions are favorable.

- Cost-effective: It reduces the need for expensive casing and cementing materials.

- Faster: Eliminates the time required to run and cement casing strings.

- Wellbore stability: Requires a stable rock formation, limiting its use in formations prone to collapse.

- Increased risk: The open hole can be more susceptible to issues like fluid loss, wellbore instability, and differential sticking.

How Do Hole Openers Work?

Hole openers are specialized drilling tools used to enlarge an existing borehole. They’re not for creating new holes from scratch. They’re typically used after a smaller-diameter “pilot hole” has already been drilled.

Here’s how they work:

- Pilot Hole Drilling: A standard drill bit first drills a small-diameter hole, called a pilot hole. This hole establishes the path and trajectory of the well.

- Tool Attachment: The hole opener is then attached to the drill string and lowered into the pilot hole. A key feature is the “bull nose” or pilot bit at the front of the tool, which is a non-cutting guide that fits snugly into the pilot hole, ensuring the hole opener stays on the correct path.

- Enlargement Process: As the drill string rotates, the cutting elements on the hole opener—either roller cones or fixed cutters (like PDC cutters)—scrape and break away the rock or soil from the walls of the pilot hole. This action progressively widens the hole to the desired diameter.

Hole openers are a cost-effective solution for creating large-diameter holes, especially in horizontal directional drilling, because it is often more efficient to drill in stages rather than attempting to drill a large hole all at once.

What is Hole Opener Used for?

Hole openers are versatile tools used across various drilling applications to efficiently enlarge a pre-drilled pilot hole. They are essential for creating boreholes of a specific, larger diameter required for subsequent operations. Their primary uses include:

- Enlarging Wellbores: This is the most common application, allowing for the installation of larger casings or improving fluid circulation and well productivity.

- Horizontal Directional Drilling: Hole openers are crucial in trenchless technology for expanding the initial pilot bore to accommodate pipelines or utility lines.

- Wiper Trips: They are used to ensure the hole is to gauge, reaming out any tight spots or ledges that may have formed, which is critical in deviated or directional drilling.

- Stabilization and Reaming: Hole openers can be run as part of the bottom-hole assembly to stabilize the drill string and ream the hole simultaneously.

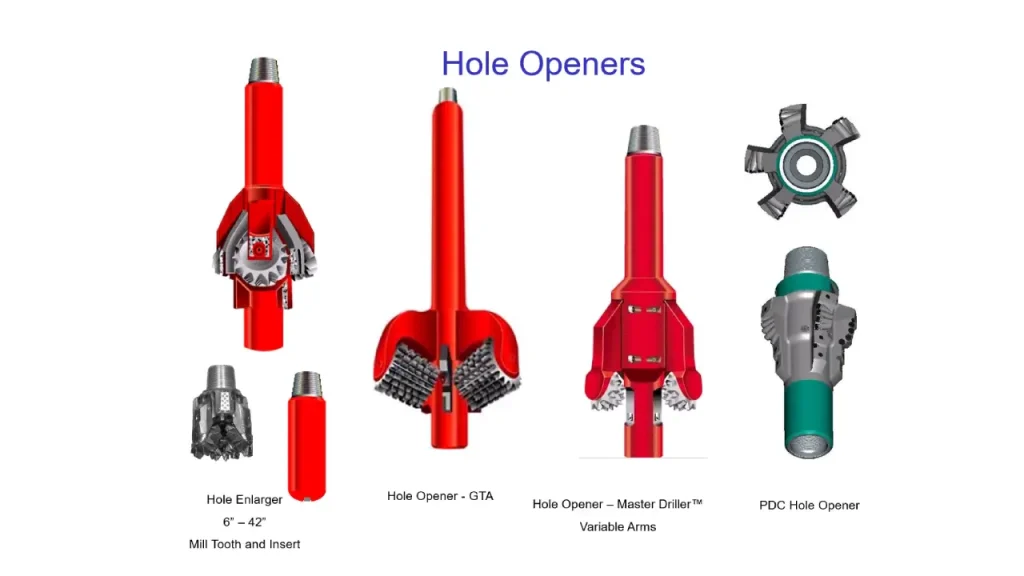

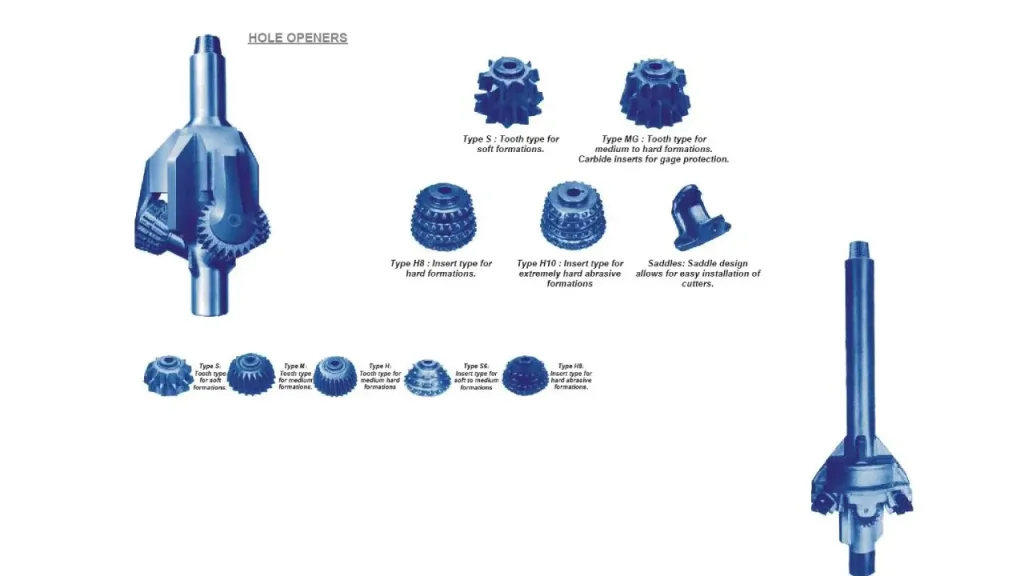

Types of Hole Openers

Different types of hole openers are designed to meet specific drilling requirements, from varying rock formations to different project scales. Each type has a unique design and cutter configuration optimized for particular applications and ground conditions.

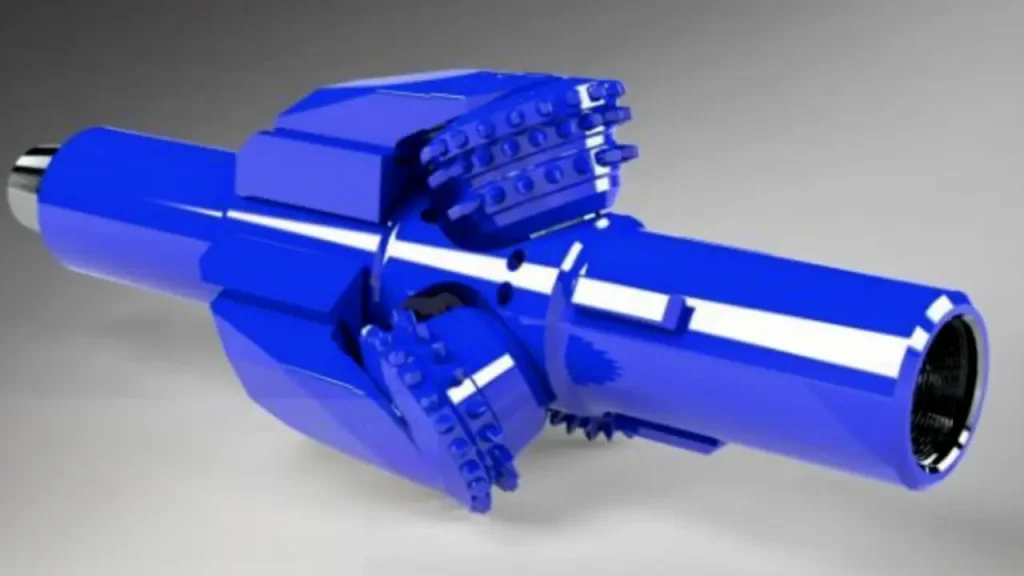

Fixed-Diameter Hole Openers

Fixed-diameter hole openers are non-adjustable tools with a set cutting diameter. They are known for their simplicity and robustness, making them a reliable choice for consistent drilling in a specific size. These tools are typically more rigid than adjustable types and are well-suited for stable formations where a single, predetermined hole size is required.

Their solid body design provides excellent stability, which helps to maintain a straight and in-gauge borehole. Because they lack moving parts for diameter adjustment, fixed-diameter hole openers are less prone to mechanical failure. They are often used in applications like reaming for casing installation or creating pilot bores for foundational piling.

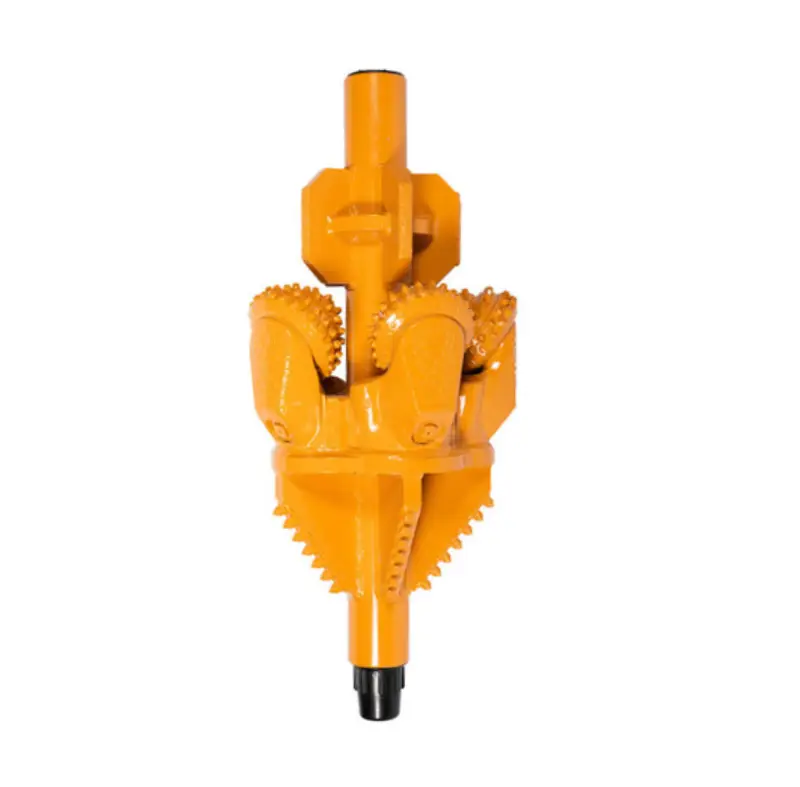

Adjustable Hole Openers

Adjustable hole openers offer the flexibility to change the reaming diameter by adjusting the position of the cutters. This versatility allows a single tool to be used for multiple hole sizes, reducing the need for an extensive inventory of fixed-size tools on a job site. This is particularly useful in projects with varying borehole size requirements.

The adjustability of these tools makes them a cost-effective and efficient solution for contractors. They are commonly used in trenchless technology and horizontal directional drilling, where the pilot bore is often progressively enlarged in several stages. While offering great flexibility, their design may be slightly less rigid than fixed-diameter models, so proper operational care is necessary to ensure optimal performance.

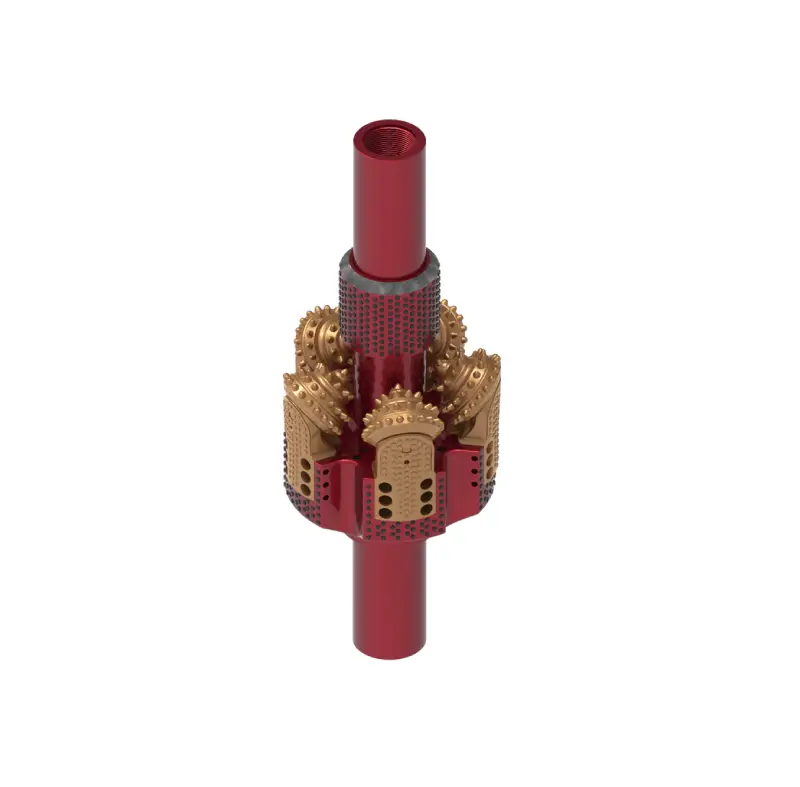

Roller Cone Hole Openers

Roller cone hole openers are designed with multiple rolling cutters, similar to those found on a tricone drill bit. These cutters rotate on the face of the formation, breaking rock through a crushing and chipping action. This makes them exceptionally effective for drilling in hard, abrasive rock formations where other cutter types might wear down quickly.

The cutting action of roller cones is highly efficient in hard rock, and the design allows for greater stability and less vibration during the reaming process. They come in both fixed- and adjustable-diameter configurations, making them a versatile choice for a wide range of applications, from mining to deep oil and gas drilling.

Fixed Cutter Hole Openers

Fixed cutter hole openers, also known as drag-type reamers, utilize fixed cutting elements, such as Polycrystalline Diamond Compact (PDC) cutters or tungsten carbide inserts. These tools ream the hole by shearing and scraping the formation, making them highly effective in softer to medium-hard formations like shale, claystone, and sandstone.

The lack of moving parts in the cutting structure makes fixed cutter hole openers durable and less susceptible to damage from junk in the hole. PDC cutters, in particular, offer a fast rate of penetration and a long lifespan in appropriate formations, making them a cost-effective solution for many projects.

PDC Hole Openers

PDC (Polycrystalline Diamond Compact) hole openers use fixed, non-rotating cutters made of synthetic diamond. These cutters shear and scrape the formation as the tool rotates, making them exceptionally effective in soft to medium-hard rock formations like shale, sandstone, and claystone.

PDC hole openers offer a high rate of penetration and have a longer lifespan in the right conditions compared to other cutter types. Because they lack moving parts, they are less prone to mechanical failure and are not as sensitive to junk in the hole. This makes them a reliable and low-maintenance choice for many drilling applications.

Mill Tooth Hole Openers

Mill tooth hole openers feature steel-toothed cutters that are machined directly from the roller cone body. These cutters are designed for reaming in soft to medium-hard formations, where their aggressive tearing and gouging action is most effective. The teeth can be chisel-shaped or conical, optimized for specific formation types.

While not as durable in hard, abrasive rock as tungsten carbide or PDC cutters, mill tooth hole openers are highly efficient in formations like soft shales and limestone. Their robust, one-piece construction makes them a reliable and economical choice for many drilling applications, particularly in the shallow depths of oil and gas and in geotechnical work.

Hole Opener With Bull Nose

A bull nose is an important feature on a hole opener, essentially a non-cutting, rounded guide at the very front of the tool. This bull nose serves several critical functions that improve drilling efficiency and control. It acts as a pilot, guiding the reamer along the pre-drilled pilot hole and ensuring it stays on the correct trajectory without wandering. This is particularly important in directional drilling or when enlarging long, deep boreholes.

Additionally, the bull nose protects the cutters from direct impact with the bottom of the hole, preserving their lifespan and preventing damage. It also helps to stabilize the entire bottom hole assembly, reducing vibration and contributing to a smoother reaming operation.

- Pilot Guide: It precisely follows the existing pilot hole, ensuring the hole opener maintains the correct path and prevents any deviation.

- Cutter Protection: Shields the cutting structures from premature wear and damage by absorbing the initial contact at the bottom of the borehole.

- Enhanced Stability: Provides a solid point of contact for the reamer, stabilizing the drill string and reducing harmful vibrations during the reaming process.

- Improved Hole Quality: By guiding the tool smoothly, the bull nose helps to create a straighter, more in-gauge borehole with a cleaner finish.

Hole Opener Cutters

Hole opener cutters are the primary cutting elements that do the work of enlarging the borehole. These cutters are available in several distinct types, each designed to perform optimally in different geological conditions. The type of cutter used is a critical factor in the hole opener’s performance, determining its rate of penetration, durability, and overall efficiency in a specific formation.

Selecting the correct cutter type for the job ensures you maximize drilling performance and tool life.

- Type MN (Milled Tooth): Designed for soft formations like shale, sand, and soft limestone. Its aggressive tooth design efficiently tears and gouges the rock, ensuring a high rate of penetration and effective cutting in these less consolidated formations.

- Type M (Milled Tooth): Suitable for medium formations such as shale, sand, and lime. The tooth design is more robust than Type MN, providing a balance of cutting efficiency and durability for formations that are slightly harder and more abrasive.

- Type H (Milled Tooth): Optimized for medium-hard formations, including lime with chert, dolomite, and sandstone. Its stronger tooth structure and geometry are engineered to withstand the increased stress of reaming harder rock while maintaining good cutting performance.

- Type H8 (Tungsten Carbide Insert): A carbide-insert type designed specifically for hard, abrasive formations like sandy lime, cherty granite, and quartzite. The tungsten carbide inserts provide exceptional wear resistance and durability, effectively crushing and chipping away at the toughest rock.

How to Choose Suitable Hole Openers?

Choosing the right hole opener is crucial for a successful and efficient drilling operation. Several key factors should guide the selection process to ensure optimal performance and tool longevity. Here are the primary considerations:

- Formation Type: Match the cutter type to the geological formation. For hard rock, use roller cone or tungsten carbide cutters. For softer formations, fixed-cutter (PDC) or mill tooth cutters are more efficient.

- Hole Diameter and Depth: Ensure the hole opener’s cutting diameter is appropriate for the desired final hole size. For deeper or longer boreholes, consider a more robust and stable design to handle increased torque and weight.

- Drilling Rig and Equipment: Verify that your drilling rig has the horsepower, torque, and mud pump capacity to operate the chosen hole opener effectively. The tool’s connection type must also be compatible with your drill string.

- Operational Environment: Consider factors like temperature, fluid type, and potential for foreign objects in the hole. This may influence your choice of materials and cutter protection features.

- Cost-Effectiveness: Balance the initial cost of the tool with its expected lifespan and performance in your specific application. Sometimes, a more expensive, durable tool can be more economical in the long run.

Conclusion

In conclusion, the hole opener is a versatile and indispensable tool for any serious drilling operation. By understanding its various types and applications, you can significantly enhance your drilling efficiency and achieve superior results. The ability to precisely and quickly enlarge a pilot hole is a game-changer, saving you time and money on the job site.

Remember, selecting the right hole opener for your specific needs is paramount. Factors such as formation type, desired hole size, and drilling rig capabilities all play a role in making the best choice. With the right knowledge, you can ensure your projects are completed with maximum precision and productivity.

For all your drilling needs, including high-quality hole openers, consider Sinodrills. We offer a wide range of wholesale hole openers designed for durability and performance, ensuring you have the right tools for every job. Contact us today to learn more about our products and how we can support your drilling projects.