Self-drilling anchors (SDAs) are innovative solutions for ground engineering, combining drilling, grouting, and anchoring into a single operation. This guide will explore the mechanics, benefits, and diverse applications of these versatile anchors, offering a comprehensive understanding for both beginners and experienced professionals.

Discover how SDAs streamline construction processes, especially in challenging ground conditions. We’ll delve into their components, installation methods, and the critical factors that make them an ultimate choice for various geotechnical projects.

What is Self Drilling Anchor?

Recommended Self Drilling Anchors

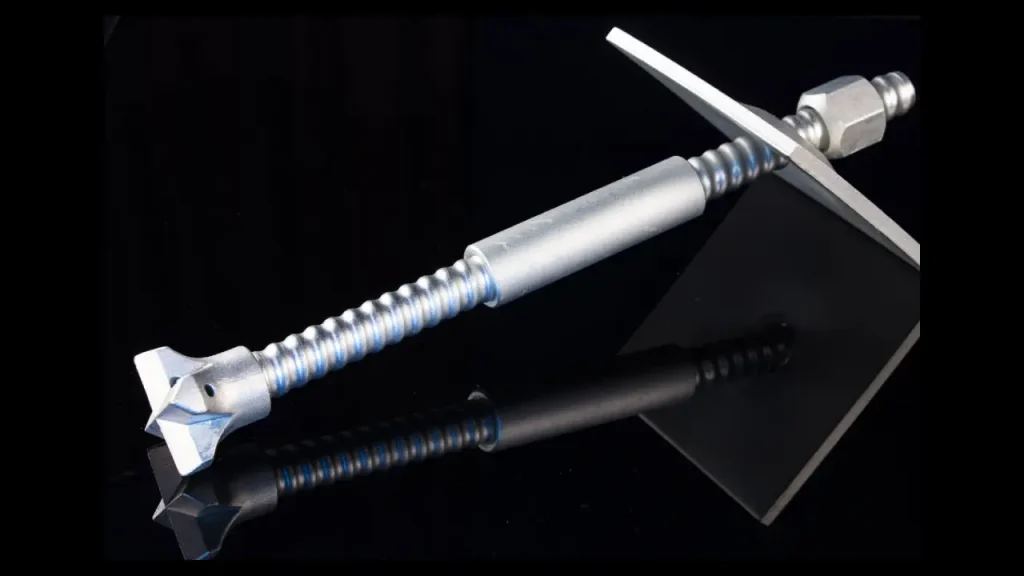

A self-drilling anchor is a specialized type of anchoring system designed to simplify and accelerate the installation process in various ground conditions, particularly those that are unstable or challenging.

Unlike traditional anchors that require a separate pre-drilled borehole, self-drilling anchors combine the drilling, grouting, and anchoring steps into a single, continuous operation.

What are Self Drilling Anchors used for?

Self-drilling anchors are versatile and widely utilized in various construction and geotechnical applications, particularly where ground conditions are challenging or traditional methods are inefficient. Their primary uses include:

- Slope Stabilization: Preventing landslides and erosion by anchoring unstable soil and rock masses.

- Tunnel Support: Providing immediate and long-term reinforcement for tunnel excavations, especially in fractured or loose ground.

- Foundation Underpinning (Micropiles): Strengthening existing foundations or creating new ones in difficult soil conditions, transferring loads to stable ground.

- Excavation Support (Soil Nailing): Reinforcing the faces of temporary or permanent excavations to prevent collapse.

- Retaining Walls: Anchoring retaining structures to resist lateral earth pressures and ensure stability.

- Embankment Stabilization: Reinforcing embankments for roads, railways, and other infrastructure to prevent settlement and failure.

- Forepoling/Spiling: Providing pre-support in tunneling by installing anchors ahead of the excavation face to stabilize the ground.

- Ground Consolidation and Injection: Injecting grout into weak or fractured ground to improve its strength and stability.

Types of Self Drilling Anchors

Self-drilling anchors streamline construction by integrating drilling and anchoring into one step, ideal for challenging ground conditions. They reduce installation time and enhance stability in various applications.

R-Thread Self-Drilling Anchors

Recommended R Thread Self-drilling Anchors

These anchors feature a continuous “R” (rope) thread profile along their entire length. This robust threading allows for strong engagement with the surrounding grout and ground, providing excellent load transfer. R-thread anchors are versatile and widely used in civil engineering applications such as slope stabilization, tunnel reinforcement, and foundation support, particularly in fractured rock or competent soil conditions.

T-Thread Self-Drilling Anchors

Recommended T Thread Self-drilling Anchors

T-thread self-drilling anchors are distinguished by their larger pitch and greater profile angle compared to R-thread anchors. This design can offer enhanced bonding with the grout and potentially higher pull-out resistance in certain ground types. They are often chosen for projects requiring high load-bearing capacity and robust anchoring in demanding geological environments, including those with varying soil and rock characteristics.

GFRP Self-Drilling Anchors

GFRP (Glass Fiber Reinforced Polymer) self-drilling anchors are made from composite materials, offering significant advantages where corrosion resistance or non-metallic properties are crucial. These anchors are lightweight, durable, and resistant to chemical degradation, making them suitable for environments with aggressive groundwater or where future excavation might require easy cutting of the anchor. Their applications include temporary ground support, tunneling, and areas subject to magnetic fields.

How to Install Self-Drilling Anchors?

Installing self-drilling anchors is an efficient process that combines drilling and anchoring into a single operation. This method is particularly advantageous in unstable ground conditions, as it minimizes borehole collapse and speeds up installation.

Step 1: Site Investigation and Preparation

A thorough site investigation is the crucial first step. This involves understanding the geological conditions, identifying any underground utilities, and assessing accessibility for equipment. Proper planning, including anchor design and material selection, is essential for a successful and safe installation.

Before drilling commences, the chosen drill rig must be carefully mobilized and set up. This includes positioning and leveling the machine at the precise anchor location to ensure drilling accuracy. All necessary components, such as the drill bit, hollow anchor bar, and grouting lines, are prepared and connected.

Step 2: Drilling and Grouting

The core of the installation involves simultaneously drilling and grouting. The self-drilling anchor bar, equipped with a sacrificial drill bit, is rotated and advanced into the ground by the drill rig. As the anchor penetrates the soil or rock, a flushing medium or cementitious grout is continuously pumped through its hollow core.

This simultaneous grouting process is vital for stabilizing the borehole, especially in loose or fractured ground, preventing collapse. The grout fills any voids, ensuring a solid bond between the anchor and the surrounding material, which is crucial for the anchor’s load-bearing capacity and long-term performance.

Step 3: Grout Curing and Head Installation

Once the anchor reaches the design depth and the borehole is fully grouted, the pumping of grout is stopped. The anchor is then left undisturbed to allow the grout to cure and gain its specified strength. The curing time varies depending on the grout type, mix design, and environmental conditions.

After the grout has adequately cured, the anchor head is installed. This typically involves attaching a bearing plate and nut to the exposed end of the anchor bar. The bearing plate distributes the load, while the nut secures the anchor in place, completing the installation process.

Cost of Self Drilling Anchor

The cost of self-drilling anchors can vary significantly, ranging from a few dollars for small, light-duty anchors used in household applications to hundreds or even thousands of dollars for larger, high-performance anchors used in civil engineering projects. Several factors influence the overall cost:

- Anchor Type and Size: Different types (R-thread, T-thread, GFRP) and sizes (diameter and length) have different material requirements and manufacturing complexities, directly impacting the price. Larger and stronger anchors naturally cost more.

- Material: The material of the anchor (e.g., steel, stainless steel, GFRP) plays a significant role. Stainless steel and GFRP anchors, offering superior corrosion resistance, are typically more expensive than standard steel anchors.

- Quantity: As with most products, purchasing in bulk usually leads to a lower unit cost.

- Supplier and Brand: Prices can vary between manufacturers and distributors based on their production processes, quality control, and brand reputation.

- Project Specifics: The overall project cost will also include installation labor, equipment rental (drill rigs, grout pumps), and the cost of grout, which can be substantial depending on the project’s scale and complexity.

- Geological Conditions: In challenging ground conditions (e.g., highly fractured rock, very loose soil), the installation might require more specialized drill bits or techniques, potentially increasing costs.

Can You Reuse Self Drilling Anchors?

Generally, self-drilling anchors are not designed for reuse in their original hole, especially in critical structural applications. Once installed and grouted, the anchor becomes an integral part of the ground support system, with the grout forming a strong bond that’s difficult to break without compromising its integrity.

Attempting to extract and re-install a self-drilling anchor can damage the anchor bar, the drill bit, or the surrounding ground/grout, severely reducing its load-bearing capacity and reliability. For temporary applications, where low loads are involved, or specific drywall anchors, some limited reusability might be possible, but it’s not recommended for structural safety.

Self Drilling Anchor Benefits

Self-drilling anchors offer significant advantages over traditional anchoring methods, stemming from their integrated drilling and grouting process. These benefits contribute to increased efficiency, safety, and versatility in diverse construction and engineering projects.

Enhanced Installation Speed

One of the primary benefits of self-drilling anchors is their significantly faster installation time. By combining the drilling of the borehole and the placement of the anchor into a single operation, they eliminate the need for pre-drilling or separate casing installation. This streamlined process drastically reduces project timelines and labor costs, particularly in large-scale applications.

Adaptability to Difficult Ground Conditions

Self-drilling anchors excel in challenging geological formations where traditional methods struggle. They can effectively penetrate and stabilize loose, fractured, or collapsing ground conditions without the need for additional casing. The continuous flushing and grouting during drilling help to consolidate the borehole, preventing caving and ensuring a stable installation in adverse soil and rock types.

Reduced Equipment and Manpower

The integrated nature of self-drilling anchor installation means fewer pieces of specialized equipment are required on-site. This reduces mobilization costs and the complexity of logistics. Furthermore, the efficiency of the process often translates to a smaller crew needed for installation, leading to further savings in labor costs and improved site management.

Improved Safety

The reduced need for manual handling of separate components and the elimination of complex multi-step procedures enhance safety on the job site. By minimizing the time workers spend in potentially unstable ground conditions, the risk of accidents is significantly lowered. The controlled drilling and grouting process also contributes to a safer working environment.

High Load-Bearing Capacity

Despite their efficient installation, self-drilling anchors can achieve high load-bearing capacities. The continuous grouting ensures excellent bond development between the anchor bar, the grout, and the surrounding ground. This creates a robust and stable anchoring system capable of withstanding significant tensile and compressive forces, making them suitable for critical structural applications.

Self Drilling Anchor Applications

Self-drilling anchors are highly versatile and widely used in various engineering and construction scenarios due to their efficiency and adaptability to challenging ground conditions. Their ability to combine drilling and grouting in a single operation makes them a preferred choice for numerous applications.

Slope Stabilization

Self-drilling anchors are extensively used for stabilizing unstable slopes, preventing landslides and erosion. They are drilled into the slope face and grouted, providing passive or active resistance against soil movement. This method is particularly effective in areas with difficult access or where conventional anchoring techniques are impractical, offering long-term stability for natural and engineered slopes.

Tunneling and Mining

In tunneling and mining operations, self-drilling anchors play a crucial role in providing immediate ground support. They are installed quickly to stabilize rock and soil ahead of the excavation face, preventing collapses and ensuring worker safety. Their ability to be installed in challenging ground conditions, including fractured rock and squeezing ground, makes them invaluable for rapid and effective ground control in underground environments.

Foundation Support and Underpinning

Self-drilling anchors are an excellent solution for underpinning existing foundations or providing support for new structures, especially in areas with poor bearing capacity or where traditional piling is not feasible. They transfer structural loads to deeper, more competent soil or rock layers, preventing settlement and ensuring the long-term stability of buildings, bridges, and other infrastructure.

Marine and Coastal Engineering

In marine and coastal environments, self-drilling anchors are employed for securing structures like seawalls, wharves, and jetties. Their corrosion-resistant options, such as GFRP anchors, are particularly valuable in saltwater conditions where steel anchors would rapidly degrade. They provide reliable anchoring in submerged or saturated ground, crucial for the longevity and stability of coastal infrastructure.

Temporary Ground Support

Self-drilling anchors are frequently used for temporary ground support during excavation for basements, trenches, or retaining walls. They offer rapid installation and provide immediate stability to the surrounding soil, minimizing the risk of collapse during construction activities. Once the permanent structure is in place, these temporary anchors can often be left in the ground, saving time and resources on removal.

How to Choose the Best Self Drilling Anchor

Choosing the best self-drilling anchor requires a careful evaluation of various project-specific factors to ensure optimal performance and cost-effectiveness. The selection process should always begin with a thorough understanding of the site’s geological conditions and the structural demands of the application.

- Geological Conditions: Different soil and rock types necessitate specific anchor designs. For instance, highly fractured rock might benefit from a robust R-thread, while cohesive soils could be suitable for T-thread profiles, ensuring maximum bond strength and efficient drilling.

- Load Requirements: The anticipated tensile, compressive, and shear loads that the anchor needs to withstand are critical. This dictates the required diameter and steel grade of the anchor bar, ensuring the chosen anchor can safely support the design loads without failure.

The desired service life and environmental factors also heavily influence the choice of anchor material and corrosion protection. Consider long-term durability and the potential for aggressive ground conditions.

- Corrosion Resistance: In aggressive environments like saltwater or areas with corrosive groundwater, specifying stainless steel or GFRP anchors is essential for longevity. These materials resist degradation, ensuring the anchor’s integrity over its design life.

- Installation Equipment: Compatibility with available drilling equipment is practical. Ensure the chosen anchor system can be efficiently installed with the drill rigs and grouting equipment on hand, optimizing the installation process.

Conclusion

Self-drilling anchors offer a highly efficient and reliable solution for various construction needs, streamlining the drilling and anchoring process. Their versatility and robust performance make them indispensable in challenging ground conditions.

For a comprehensive range of high-quality self-drilling anchors, consider Sinodrills. We provide wholesale options to meet your project demands, ensuring you have access to top-tier equipment.

Choose Sinodrills for your self-drilling anchor needs and experience the benefits of superior products and dedicated service.