Custom 5 Wing PDC Drill Bit Manufacturer in China

As a custom 5 wing PDC drill bit manufacturer in China, we offer tailored designs to match different formations and drilling requirements. Our 5 wing PDC drill bits feature durable PDC cutters, stable cutting structure, and precise machining, delivering efficient penetration, smooth drilling performance, and long service life for oil, gas, and geological drilling projects.

Sinodrills - Your Trusted 5 Wing PDC Drill Bit Manufacturer from China

Sinodrills is your trusted 5 wing PDC drill bit manufacturer from China, delivering reliable solutions for oil, gas, and geological drilling. We combine advanced manufacturing, strict quality control, and customized designs to produce durable 5 wing PDC drill bits with stable performance, efficient cutting, and long service life in complex formations worldwide.

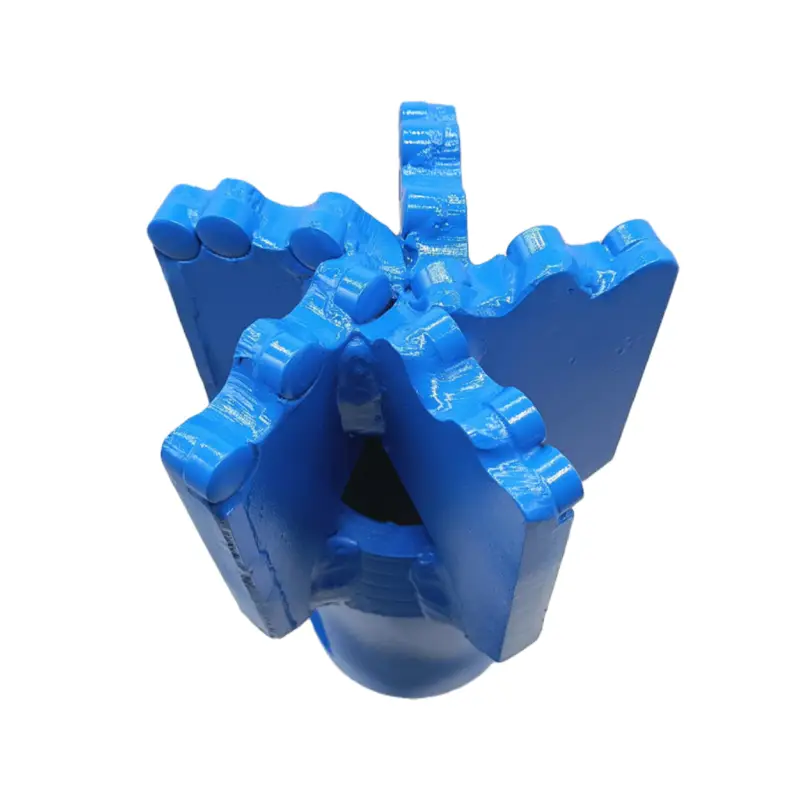

Various 5 Wing PDC Drill Bit

Standard 5 Wing PDC Drill Bits

Standard 5-wing PDC drill bits are a type of fixed-cutter bit with five blades embedded with Polycrystalline Diamond Compact (PDC) cutters. This design provides enhanced stability, improved cutting efficiency, and exceptional durability. They are ideal for drilling in soft to medium-hard formations like shale, sandstone, and limestone, offering a high rate of penetration and long tool life.

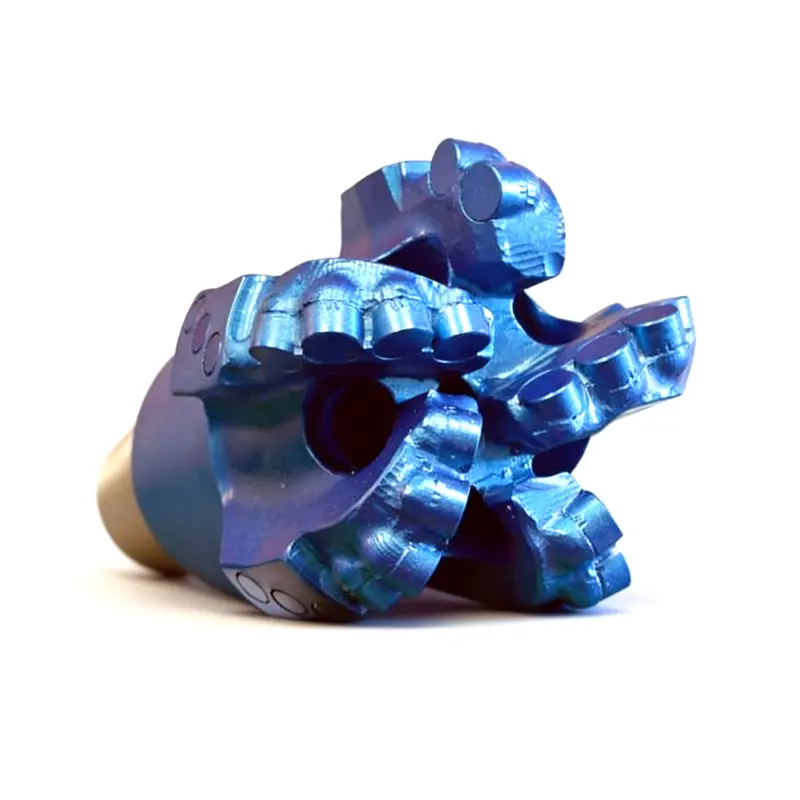

Aggressive 5 Wing PDC Drill Bits

Experience unparalleled drilling efficiency with our aggressive 5-wing PDC drill bits. Designed for maximum penetration and durability, these bits feature premium polycrystalline diamond cutters for superior performance in soft to medium-hard formations. The optimized design ensures fast ROP, extended bit life, and reduced drilling costs.

5 blade Drag drill bits

Our 5-blade drag bits are engineered for superior performance in soft to medium-hard formations like sand, clay, and soft shale. The five-wing design provides exceptional stability, minimizing vibration and ensuring a straighter hole. With a balanced cutter placement and enhanced hydraulics, these bits offer fast penetration and efficient cuttings removal, extending bit life and reducing overall drilling costs.

5 wings deep oil drilling diamond fixed cutters PDC bits

Harness superior performance for deep oil drilling with our 5-wing PDC bits. Featuring fixed polycrystalline diamond cutters, these bits are engineered for exceptional durability and rapid penetration in various geological formations. The advanced design ensures enhanced stability, optimal fluid dynamics, and a longer tool life, significantly boosting drilling efficiency and reducing costs.

5 wing PDC concave drill bit

Our 5-wing PDC concave drill bits are engineered for exceptional performance in soft to medium-hard formations. The concave face and five-bladed design enhance stability and torque control, delivering a high rate of penetration (ROP) and a straighter hole. With superior wear resistance and durability, these bits offer a long service life and reduce overall drilling costs.

5 wing long blade drag drill bit

Our 5-wing long blade drag bits are designed for superior performance in soft to medium-hard formations. The long, aggressive blades with tungsten carbide tips ensure a fast rate of penetration and efficient removal of cuttings, preventing bit “balling.” Ideal for water well, mining, and exploration drilling, these bits offer excellent durability and a long service life.

5 wing PDC bit for water well drilling

Our 5-wing PDC bits for water well drilling are engineered for peak performance in soft to medium-hard formations. The aggressive cutting structure, featuring premium polycrystalline diamond cutters, delivers a superior rate of penetration (ROP) and exceptional durability. The optimized design ensures efficient cuttings removal and extended bit life, reducing drilling costs and downtime.

5 wing diamond core drill bit

Our 5-wing diamond core drill bits are engineered for superior performance in hard and abrasive formations. Featuring premium industrial diamonds, these bits deliver exceptional cutting efficiency, extended tool life, and precise core recovery. The 5-wing design enhances stability and flush across a wide range of applications, optimizing drilling speed and reducing costs.

API reg pin 5 wing pcd bit

Our API Reg Pin 5-wing PDC bits deliver superior drilling performance, specifically designed for various geological conditions. Featuring robust polycrystalline diamond compact cutters and an API Regular Pin connection, these bits ensure efficient penetration, extended bit life, and reduced vibration. Experience reliable and cost-effective drilling with optimized ROP and enhanced durability.

5 blade steel body PDC drill bits

Our API Reg Pin 5-wing PDC bits deliver superior drilling performance, specifically designed for various geological conditions. Featuring robust polycrystalline diamond compact cutters and an API Regular Pin connection, these bits ensure efficient penetration, extended bit life, and reduced vibration. Experience reliable and cost-effective drilling with optimized ROP and enhanced durability.

5 blade button drill bits

We offer 5 blade button drill bits designed for efficient rock breaking, stable drilling, and extended service life. Featuring wear-resistant carbide buttons and balanced blade layout, our 5 blade button drill bits perform reliably in mining, quarrying, tunneling, and construction drilling applications across medium to hard rock formations.

Customize Your Desired 5 Wing PDC Drill Bit

Formation Type

We analyze the geological formation you’ll be drilling through—be it soft shale, medium sandstone, or hard limestone. This dictates the cutter size, density, and exposure we select for optimal penetration and durability against specific abrasive or compressive strengths.

Connection Type

We ensure seamless integration with your existing drilling rig by offering various connection types, including API Regular Pin, IF, and others. This guarantees a secure and efficient connection, preventing downtime and maximizing the transfer of power from the rig to the bit.

Bit Body Material

We choose between steel or matrix body materials based on the required strength and wear resistance. Steel bodies offer toughness, while matrix bodies provide superior erosion resistance in highly abrasive conditions, ensuring your bit withstands harsh downhole environments.

Nozzle Configuration

We customize the nozzle count and placement to optimize hydraulic efficiency. This controls the flow and velocity of drilling fluid, effectively cleaning the bit face, cooling the PDC cutters, and removing cuttings from the borehole for faster and more efficient drilling.

All-in-one 5 Wing PDC Drill Bit Solutions for Your Project

We provide 5-wing PDC drill bit solutions tailored to your project’s unique demands. From geological analysis to custom bit design, we ensure optimal performance in diverse formations. Our expertise delivers enhanced ROP, extended bit life, and reduced costs through superior material selection and precise engineering. Partner with us for efficient, reliable drilling results.