Milled-tooth (MT) drill bits are a foundational tool in the drilling industry, known for their efficiency in softer rock formations. This ultimate guide will demystify the design and function of MT bits, which feature teeth cut directly from the steel cone body.

Understanding this technology is key to optimizing drilling performance and selecting the most cost-effective solution for your soft-to-medium rock projects.

We’ll cover everything from their unique scraping and gouging mechanism to the specific geological environments where they excel. Whether you’re a drilling veteran or new to the field, this guide provides the crucial knowledge needed to properly select, use, and maintain milled-tooth rock bits for maximum efficiency and longevity in various applications.

What is Milled Tooth?

A Milled-Tooth (MT) bit, also known as a Steel-Tooth bit, is a type of roller cone drill bit distinguished by its cutting elements: the teeth are machined or “milled” directly from the steel body of the rotating cones. This construction results in a monolithic structure where the steel teeth are an integral part of the cone itself.

These MT drill bits are typically used in drilling applications where the rock formations are soft to medium-hard, such as soft shales, clays, and soft limestones, where they offer a cost-effective and efficient solution.

The primary mechanism of rock destruction for a milled-tooth bit is an aggressive gouging, scraping, and tearing action, which is highly effective at removing the material from less abrasive, lower compressive strength formations.

For enhanced durability, the surface of the steel teeth is often hard-faced with a wear-resistant carbide composite, especially on the gauge rows.

While they generally have a shorter operational life than their Tungsten Carbide Insert (TCI) counterparts, their simpler construction and high rate of penetration in suitable soft formations make them a staple in water well, geothermal, and shallow oil and gas drilling.

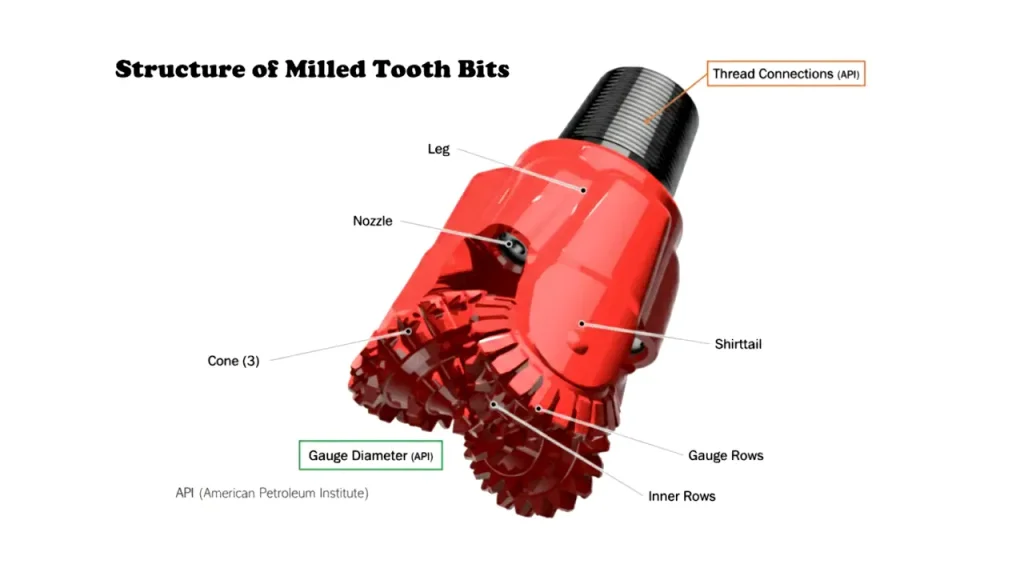

Milled Tooth Bit Structure

Understanding the intricate structure of a Milled Tooth (MT) drill bit is fundamental to appreciating its function and optimizing its performance in soft formations. Each component plays a vital role in the bit’s ability to efficiently penetrate rock, manage drilling fluids, and maintain borehole integrity. A detailed look at these parts illuminates their contribution to the overall drilling process.

From the robust steel cones with their integrated teeth to the critical bearing systems and fluid dynamics, every element is designed for specific tasks. Recognizing how these components interact under downhole conditions empowers operators to select the right bit, troubleshoot issues, and maximize the operational lifespan of the bit, ensuring effective and economical drilling.

Here’s an explanation of the key structural components of a Milled Tooth Bit:

- Thread Connections (API): Located at the top of the bit body, these threads conform to American Petroleum Institute (API) standards. They ensure a secure and robust connection between the drill bit and the drill string. This critical interface transmits rotational power, weight on bit (WOB), and drilling fluid from the surface down to the cutting elements, ensuring reliable operation throughout the drilling process.

- Leg: The leg is the main structural component extending downwards from the thread connection, housing the bearings and supporting the cones. It’s designed to withstand significant compressive and torsional forces encountered during drilling. Its robust construction ensures stability and channels drilling fluid to the nozzles, playing a crucial role in the bit’s overall integrity and performance.

- Nozzle: Nozzles are precisely engineered openings on the bit body through which drilling fluid (mud) is expelled at high velocity. Their primary functions include cooling and lubricating the cutting structure and bearings, and, most importantly, cleaning the bottom of the hole. This powerful jetting action prevents cuttings from re-drilling and ensures the teeth remain exposed to fresh rock for optimal penetration.

- Shirt Tail: The shirttail is the lower, skirt-like extension of the leg that partially covers and protects the bearing assembly. It acts as a shield against abrasive cuttings and formation debris, preventing them from entering and damaging the critical bearing components. This protection significantly extends the life of the bearing system, contributing to overall bit durability and reliability.

- Cone (3): Milled tooth bits typically feature three rotating cones, each with its own set of integrated steel teeth. These cones are designed to roll and interact with the rock formation as the bit rotates. Their unique offset and geometry are engineered to maximize the gouging, scraping, and tearing action essential for effective penetration in soft to medium-soft formations, ensuring efficient rock removal.

- Gauge Rows: These are the outermost rows of teeth or inserts located on the perimeter of each cone, responsible for maintaining the diameter of the borehole. Gauge rows cut the wellbore to its exact specified size, preventing the hole from becoming undersized. They are critical for ensuring proper casing fit and are often reinforced with hardfacing or inserts to resist wear and maintain hole integrity.

- Inner Rows: The inner rows of teeth are positioned closer to the center of the bit, extending towards the core of the wellbore. These teeth primarily break up the rock in the central part of the hole. Their design (length, shape, and spacing) is optimized to efficiently crush and shear the core material, working in conjunction with the gauge rows to achieve full-face rock destruction.

- Gauge Diameter (API): This refers to the maximum outer diameter of the drill bit, which corresponds to the size of the hole it will drill. Defined by API standards, the gauge diameter is crucial for ensuring that the wellbore is drilled to the correct size, allowing for the subsequent passage of casing or other downhole tools. Maintaining an accurate gauge is vital for overall well construction.

Tricone Bit Milled Tooth

The Tricone Bit with Milled Tooth (MT) design represents a robust and cost-effective solution for drilling in softer geological formations. Its unique construction, where cutting teeth are forged directly from the bit’s steel cones, allows for an aggressive scraping and gouging action. This mechanism efficiently removes material from formations that are less abrasive and possess lower compressive strengths, making it a staple in various drilling operations.

This type of bit is particularly favored where high penetration rates are achievable without excessive wear on the cutting structure.

Understanding its optimal applications is crucial for maximizing drilling efficiency and extending bit life, ultimately contributing to project success and cost savings.

Here are some key applications for Tricone Milled Tooth bits:

- Water Well Drilling: MT bits are extensively used in drilling water wells through unconsolidated sediments, clays, shales, and soft sandstone. Their ability to achieve rapid penetration in these softer layers makes them ideal for quickly reaching aquifers, which significantly reduces the overall time and cost associated with well installation.

- Geothermal Drilling: In geothermal projects, MT bits are often employed for drilling the upper, softer sections of the wellbore before transitioning to harder rock. They efficiently penetrate the sedimentary layers covering geothermal reservoirs, setting the stage for deeper, more challenging drilling phases with specialized equipment.

- Shallow Oil & Gas Drilling: For conventional and unconventional shallow oil and gas wells, especially in regions with soft caprock or reservoir formations, MT bits are a go-to choice. They deliver high rates of penetration through soft shales, sands, and limestones, aiding in the rapid deployment of surface and intermediate casing strings.

- Construction & Mining Exploration: Milled tooth bits find use in foundational drilling for large construction projects, such as pilings and bridge supports, and in mining exploration for overburden removal or sampling soft ore bodies. Their performance in softer ground conditions ensures efficient site preparation and accurate geological assessment.

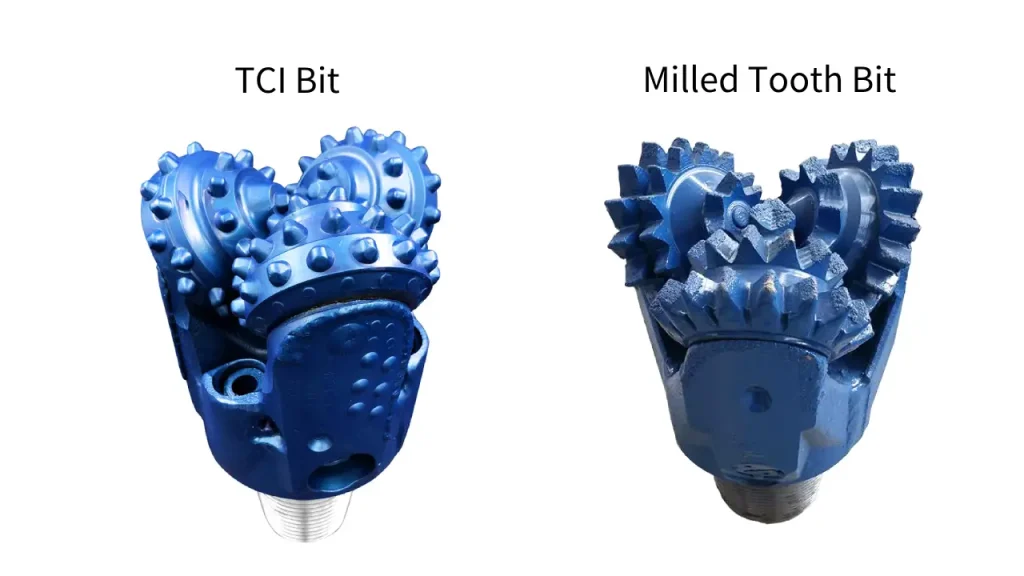

Milled Tooth Bit vs Insert Bit

Choosing between a Milled Tooth (MT) bit and an Insert (TCI) bit is critical for drilling success, as each is designed for specific rock types and drilling conditions. This comparison highlights their fundamental differences in construction, performance, and application.

Cutting Structure

Milled Tooth bits feature cutting elements that are an integral part of the steel cone body, machined directly from the steel. These steel teeth are designed to gouge, scrape, and tear through softer formations aggressively. Their robust, yet comparatively softer, steel construction is ideal for formations that don’t rapidly abrade the cutting elements, offering a cost-effective solution for shallow and softer drilling environments.

Insert bits, on the other hand, utilize individual tungsten carbide inserts (buttons) pressed into pre-drilled holes on the bit cones. Tungsten carbide is an extremely hard and wear-resistant material, allowing TCI bits to effectively crush and chip away at much harder and more abrasive rock formations. This construction significantly extends bit life and performance in challenging conditions, though at a higher manufacturing cost.

Formation Suitability

Milled Tooth bits are optimally suited for drilling through soft to medium-soft rock formations. These include materials like soft shales, clays, unconsolidated sands, gypsum, and soft limestones. In these conditions, the aggressive scraping action of the steel teeth achieves very high rates of penetration, making them highly efficient and economical.

Insert bits excel in medium to extremely hard and abrasive rock formations, such such as granite, quartzite, hard sandstone, and dolerite. The superior hardness and wear resistance of tungsten carbide inserts allow them to withstand the crushing forces required to break these dense and unyielding rocks, providing consistent performance and longer bit life in demanding environments.

Drilling Mechanism

The primary drilling mechanism of a milled tooth bit is through a combination of gouging, scraping, and tearing. As the bit rotates, the elongated steel teeth dig into the softer rock, peeling away layers of material. This action is most effective in formations that deform easily under pressure and do not cause rapid blunting or breaking of the steel teeth, maximizing material removal.

Insert bits primarily operate by crushing and chipping the rock. The hard tungsten carbide inserts concentrate immense pressure onto small areas of the rock, causing it to fracture and spall. This mechanism is ideal for brittle and hard formations, where the localized stress created by the inserts efficiently breaks the rock structure, allowing for penetration.

Bit Life and Durability

Milled Tooth bits generally have a shorter lifespan compared to TCI bits, especially when encountering harder streaks or abrasive materials. The steel teeth are more susceptible to wear, blunting, and deformation when subjected to highly abrasive or high-compressive-strength rocks. Regular monitoring for tooth wear is crucial to ensure efficient drilling and prevent premature bit failure.

Insert bits boast significantly longer bit life and superior durability due to the exceptional hardness and wear resistance of tungsten carbide. They can maintain their cutting edge for extended periods in abrasive and hard rock environments, reducing the frequency of bit trips. This extended durability translates to less downtime and greater overall drilling efficiency, especially in deep or complex wells.

Cost

Milled Tooth bits typically have a lower manufacturing cost, which translates to a lower purchase price. This makes them a more economical choice for projects primarily involving soft formations, where their shorter lifespan is offset by their initial affordability and high penetration rates in suitable ground. They represent a good value proposition for specific applications.

Insert bits are generally more expensive due to the higher cost of tungsten carbide materials and the more complex manufacturing process involved in precisely setting each insert. However, their extended lifespan and superior performance in hard formations often result in a lower cost per foot drilled over the life of the bit, justifying the higher initial investment for challenging conditions.

| Feature | Milled Tooth (MT) Bit | Insert (TCI) Bit |

| Cutting Structure | Steel teeth milled from cone body | Tungsten carbide inserts pressed into cones |

| Formation Suitability | Soft to medium-soft (e.g., shale, clay, soft limestone) | Medium to extremely hard (e.g., granite, quartzite) |

| Drilling Mechanism | Gouging, scraping, tearing | Crushing, chipping |

| Bit Life & Durability | Shorter lifespan, susceptible to wear in hard rock | Longer lifespan, highly durable in hard rock |

| Cost | Lower initial cost | Higher initial cost |

| Rate of Penetration (ROP) | High in soft formations | High in hard formations |

How to Choose Milled Tooth Drill Bits?

Selecting the correct Milled Tooth (MT) drill bit is crucial for optimizing drilling efficiency and maximizing bit life in soft to medium-soft formations. An informed choice ensures that the bit’s design features align perfectly with the specific geological conditions and operational parameters of your drilling project. This guide will walk you through the key factors to consider, helping you make the most effective selection.

Understanding these critical selection criteria will not only enhance your drilling performance but also contribute to significant cost savings by reducing downtime and avoiding premature bit failures. By carefully evaluating each aspect, you can ensure that your chosen MT bit delivers optimal penetration rates and durability in its intended application.

Here’s how to choose Milled Tooth drill bits effectively:

Formation Hardness and Abrasiveness:

Assess the compressive strength and abrasiveness of the rock. For very soft, non-abrasive formations like unconsolidated sand or soft clay, bits with longer, more widely spaced teeth are effective. As formations become slightly harder or mildly abrasive (e.g., firm shale), choose bits with shorter, more closely spaced teeth and robust hardfacing for improved wear resistance and crushing action.

Tooth Geometry (Length, Spacing, Shape):

Longer, widely spaced teeth with aggressive chisel shapes are ideal for soft formations, allowing for maximum penetration and removal of large cuttings. For firmer formations, consider shorter, more numerous, and closely spaced teeth, possibly with a slight rounding or cone shape, which provide better strength and more even distribution of impact to prevent premature wear.

Cone Offset:

Cone offset refers to the degree to which the cones are displaced from the bit’s centerline. A higher offset increases the scraping and twisting action, which is highly effective for soft formations, promoting faster penetration. For slightly firmer formations, a moderate offset balances the scraping action with a more stable rolling motion, preventing excessive wear on the bit’s gauge.

Bearing Type:

The bearing system dictates the bit’s durability and ability to handle downhole conditions. For typical shallow water well or construction drilling in soft rock, open or sealed roller bearings might suffice, offering a balance of cost and performance. For more demanding applications or longer runs, sealed journal bearings provide superior durability and longer life, crucial for preventing premature failure.

Gauge Protection:

Ensure the bit has adequate gauge protection, especially if drilling through alternating soft and slightly harder stringers, or if directional stability is critical. Enhanced gauge inserts or hardfacing on the bit’s circumference prevent wear to the bit’s diameter, ensuring the wellbore remains to size and preventing premature bit retirement due to gauge loss.

Junk Slot Area and Nozzle Configuration:

A large junk slot area is crucial for efficient removal of cuttings, particularly in soft formations that produce large volumes of material. The nozzle configuration (number and size) determines the hydraulic cleaning action, ensuring the bottom of the hole is clear of cuttings and the bit teeth remain clean for optimal penetration.

Conclusion

The milled-tooth tricone bit remains an indispensable asset for soft-to-medium formation drilling due to its cost-effectiveness and aggressive gouging action. By mastering the principles of MT bit design, including tooth shape and offset, drilling operators can ensure higher penetration rates and reduce non-productive time. Properly matching the bit’s features to the rock’s compressive strength is the ultimate secret to drilling success.

For all your soft formation drilling needs, you can secure reliable and high-performance wholesale milled tooth drill bits directly from Sinodrills. We offer a comprehensive range of sizes and designs, manufactured to the highest industry standards for optimal durability and drilling efficiency. Partner with us to maximize your operation’s productivity.

Don’t compromise on quality or performance. Contact Sinodrills today to get the best value on your bulk order of MT rock bits. Our expert team is ready to help you select the precise specifications needed for your specific geological challenges, ensuring you have the right tool for every soft drilling job.