The tricone drill bit is a cornerstone of modern drilling, crucial for efficiently penetrating diverse geological formations. Its robust design, featuring three conical rollers, allows for effective crushing and shearing of rock, making it indispensable in oil and gas, mining, and water well drilling operations.

This blog delves into the intricate world of tricone drill bit design. We’ll explore the key components, material science, and engineering principles that contribute to their performance, longevity, and adaptability in challenging downhole environments.

What is Tricone Drill Bit?

Recommended Tricone Drill Bits

A tricone drill bit is a type of rotary drill bit widely used in various drilling applications, including oil and gas, mining, and water well drilling. It is characterized by its three independently rotating conical rollers, or cones, which are fitted with cutting teeth or inserts.

As the drill string rotates, these cones roll along the bottom of the borehole, and their teeth crush, chip, and abrade the rock, breaking it into smaller fragments to create the wellbore. The design and material of the teeth (either milled steel or tungsten carbide inserts) vary depending on the hardness and characteristics of the rock formation being drilled, allowing tricone bits to be highly versatile in penetrating everything from soft soils to hard, abrasive rock.

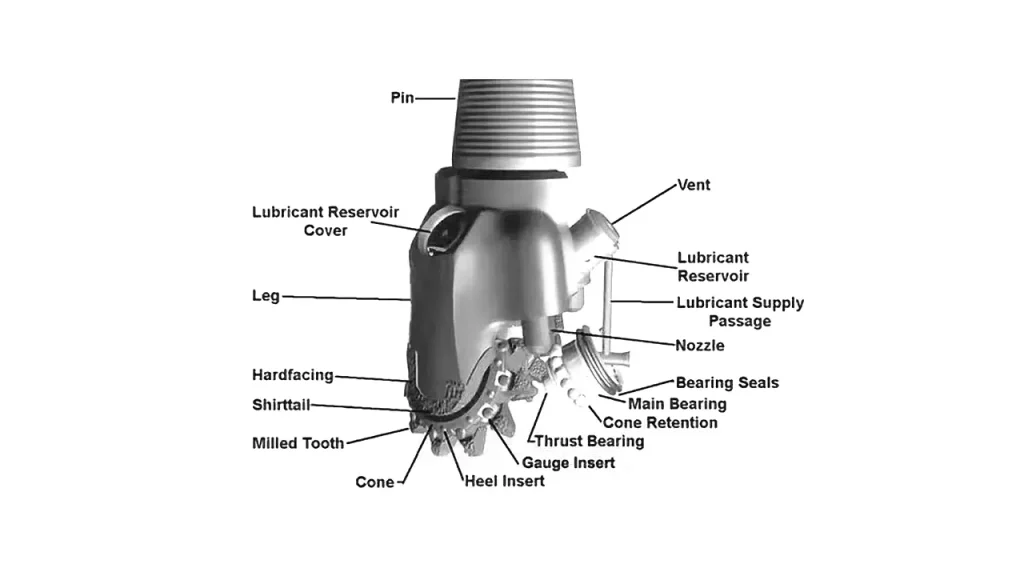

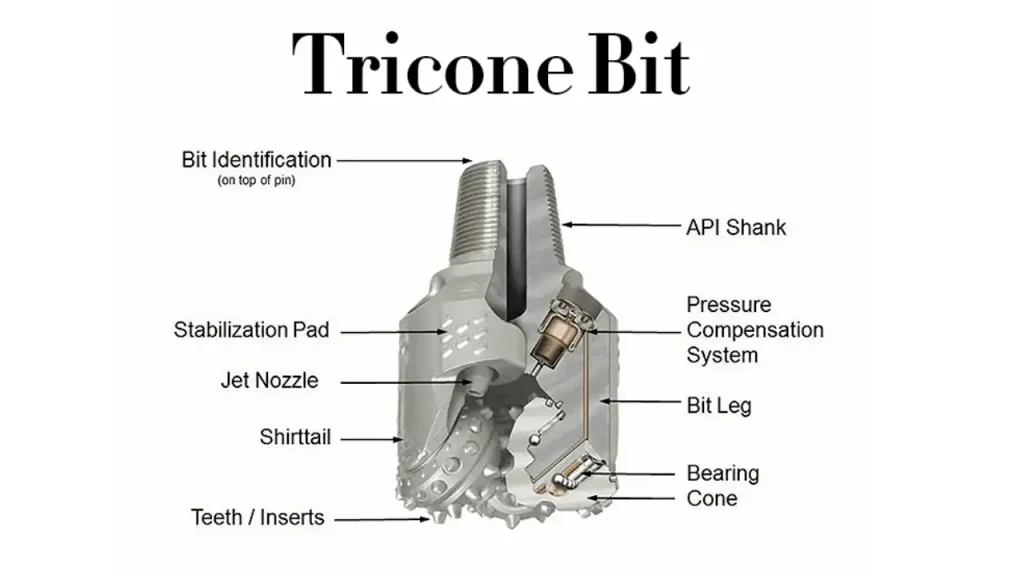

Tricone Drill Bit Components

A tricone drill bit is a complex piece of engineering designed for efficient rock penetration, comprising several critical components that work in synergy. These include:

- Cones: The three main rotating elements, featuring cutting structures on their outer surfaces.

- Cutting Structure: The teeth or inserts on the cones, made from milled steel for softer formations or tungsten carbide inserts (TCI) for harder, more abrasive rocks.

- Bearings: Located within each cone, these allow for independent rotation and reduce friction, with types including roller bearings and sealed journal bearings.

- Seal System: Crucial for protecting the bearings from abrasive drilling fluids and maintaining lubrication, often utilizing O-rings or metal face seals.

- Lubrication System: Provides oil to the bearings and seals, extending the bit’s operational life, often with a pressure compensation system.

- Bit Body/Shank: The main structural part of the bit that connects to the drill string and holds the cones, often hardfaced for wear resistance.

- Nozzles: Strategically placed orifices that allow drilling fluid to be jetted to the bottom of the hole, cooling the bit and carrying away rock cuttings.

Tricone Drill Bit Design

Tricone drill bit design is a highly specialized field, aiming to optimize performance across a vast range of geological formations. The core principle revolves around maximizing the mechanical action of the three cones to break rock efficiently. This involves careful consideration of several interconnected design elements:

Cutting Structure Optimization:

- Tooth/Insert Type: Milled steel teeth (for softer formations) or tungsten carbide inserts (TCI) (for harder, more abrasive rocks) with varying shapes (chisel, conical, spherical) and projections.

- Cone Offset: The degree to which the cones are offset from the bit’s centerline, influencing the scraping and gouging action. Greater offset is for softer formations, while little to no offset is for crushing in hard formations.

- Intermesh: The extent to which teeth or inserts on one cone penetrate the grooves of an adjacent cone, crucial for cleaning the cutting structure and preventing “balling” in sticky formations.

- Gauge Protection: Inserts or hardfacing on the bit’s outer diameter to prevent wear and maintain hole size, particularly important in abrasive formations.

Beyond the cutting elements, the internal mechanics are equally vital for longevity and efficiency. This includes:

Bearing System:

- Types: Open/roller bearings (often fluid-cooled for shallower wells or workovers) versus sealed journal bearings (oil/grease lubricated, providing superior durability for deeper, hotter wells).

- Lubrication: The type of lubricant and the effectiveness of the system in maintaining bearing integrity under high pressure and temperature.

- Seal System: The quality and design of seals (e.g., O-rings, metal face seals) that prevent drilling fluids and abrasives from contaminating the bearings.

Hydraulics:

- Nozzle Design and Placement: Optimizing the number, size, and orientation of nozzles to effectively clean the bit face, cool the cutting structure and bearings, and lift cuttings from the borehole.

- Flow Paths: Internal channels within the bit body that direct drilling fluid for efficient chip removal and hydraulic horsepower utilization.

- Materials Science: Selection of high-strength alloys for the bit body and cones, and advanced wear-resistant materials for inserts and hardfacing to ensure durability in extreme drilling environments.

How to Design a Tricone Drill Bit?

Designing a tricone drill bit is a meticulous process that balances geological demands with engineering principles. It involves a series of critical steps to create a bit optimized for specific drilling conditions.

Step 1: Formation Analysis

This initial and crucial step involves thoroughly understanding the geological formation to be drilled. Engineers analyze rock properties such as hardness, abrasiveness, and stickiness, as well as the presence of any unique challenges like interbedded layers or fractured zones. This detailed analysis forms the bedrock for all subsequent design decisions, ensuring the bit is tailored to overcome specific downhole challenges effectively.

Step 2: Cutting Structure Selection

Based on the formation analysis, the appropriate cutting structure is chosen. For softer formations, milled steel teeth are typically selected, while harder, more abrasive rocks necessitate robust tungsten carbide inserts (TCI) with specific shapes and projections. The design also considers cone offset and intermesh to optimize the crushing, gouging, and scraping actions for maximum penetration and efficient chip removal.

Step 3: Bearing and Seal System Design

The heart of the bit’s durability lies in its bearing and seal system. Designers select between open/roller bearings for less demanding applications or sealed journal bearings for high-temperature, high-pressure environments, focusing on lubrication effectiveness. The seal system is critical, employing advanced materials and designs to protect the bearings from drilling fluid contamination and ensure extended bit life in harsh downhole conditions.

Step 4: Hydraulic Optimization

Efficient hydraulics are paramount for bit performance and hole cleaning. This step involves designing the number, size, and orientation of the nozzles to effectively direct drilling fluid to cool the bit and lift cuttings. Optimal flow paths within the bit body are also engineered to maximize hydraulic horsepower at the bit face, leading to improved penetration rates and reduced bit wear.

Step 5: Material Selection and Manufacturing

Choosing the right materials is vital for the bit’s structural integrity and wear resistance. High-strength alloy steels are selected for the bit body and cones, while specialized wear-resistant materials are used for inserts and hardfacing on critical surfaces. The manufacturing process, including heat treatment and precision machining, ensures that the final product meets stringent quality standards for performance and reliability in demanding drilling operations.

Tricone Drill Bit Uses

Tricone drill bits are incredibly versatile tools, making them a staple across numerous industries that require efficient and reliable rock penetration. Their ability to adapt to varying rock hardness and formations, largely due to their diverse cutting structures and bearing types, makes them a preferred choice for:

- Oil and Gas Drilling: Widely used for drilling both shallow and deep wells, including exploration, production, and workover operations, capable of penetrating a vast range of formations from soft shales to hard granite.

- Mining: Essential for extracting various minerals, including coal, iron ore, and diamonds, by drilling blast holes, exploration holes, and production wells in diverse rock types.

- Water Well Drilling: Employed for accessing groundwater resources, particularly in areas with challenging rock formations that require robust and efficient drilling.

- Geothermal Drilling: Utilized for creating boreholes for geothermal energy extraction, often encountering high temperatures and abrasive rock.

- Construction and Geotechnical Drilling: Used for foundation drilling, piling, and other civil engineering projects where precise and deep penetration through rock, concrete, and soil is required.

Conclusion

The ongoing evolution of tricone drill bit design continues to push the boundaries of drilling efficiency and cost-effectiveness. From optimized bearing systems to advanced cutting structures and material innovations, each improvement contributes to enhanced performance in diverse geological conditions.

Understanding these design intricacies is key to selecting the right bit for your specific application, maximizing penetration rates, and extending bit life. The right bit can significantly impact project timelines and overall operational expenses.

For your drilling needs, consider the high-quality, durable PDC drill bits available wholesale from Sinodrills. Our advanced designs are engineered for superior performance and longevity, helping you achieve efficient and cost-effective drilling operations.