In the industry of rock drilling, a drill bit’s performance isn’t just about its hardness—it’s also about its efficiency. The small, often overlooked flushing holes on a drill bit play a critical role in this. These channels are engineered to perform a crucial function: clearing rock cuttings from the borehole and preventing the bit from getting stuck.

Understanding how a drill bit’s flushing system works is key to achieving optimal results on any drilling project. Proper flushing prevents bit overheating, reduces wear and tear, and ensures a faster, more consistent rate of penetration. In essence, it’s the bit’s built-in cleaning system, maximizing its performance and lifespan.

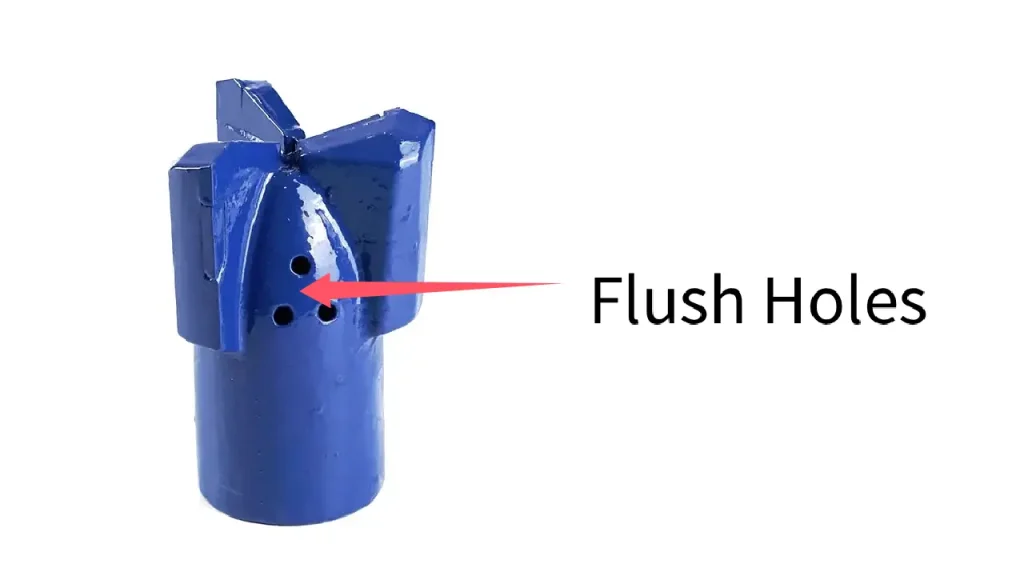

What is Drill Bit Flushing Hole?

A drill bit flushing hole is a channel or port engineered into the bit’s face and body. Its primary function is to allow a flushing medium, such as compressed air or water, to flow through the bit and out into the borehole.

As this medium exits the bit, it forcefully carries away rock cuttings and debris from the drilling area. This process is crucial for preventing the bit from getting clogged, overheating from friction, and becoming stuck in the hole. An effective flushing system ensures a clear drilling path, leading to a faster penetration rate, reduced wear on the bit, and a longer tool life.

What Does Drill Bit Flush Hole Work?

A drill bit flush hole allows smooth and efficient drilling by providing an exit path for debris, water, or slurry during the drilling process. This design reduces clogging, improves cutting efficiency, and extends the life of the drill bit in mining, construction, and tunneling applications.

- Efficient Debris Removal – We design flush holes to quickly remove rock chips, dust, and drilling debris. This prevents clogging, maintains cutting efficiency, and ensures consistent drilling speed, reducing downtime and improving overall productivity in demanding mining or construction environments.

- Enhanced Cooling and Lubrication – We use flush holes to allow water or drilling fluid to flow through the drill bit. This cools the cutting surface, reduces friction, prevents overheating, and increases the bit’s lifespan while maintaining precision during extended drilling operations.

- Improved Drilling Accuracy – We ensure that flush holes help maintain stable bit alignment by reducing resistance from accumulated debris. This allows for straighter, more precise holes, minimizing deviations and ensuring that anchor bolts or other fasteners fit securely and reliably.

- Extended Tool Life – We implement flush hole designs that reduce wear and tear on the drill bit. By minimizing friction, heat, and debris accumulation, the bit maintains its sharpness and structural integrity, delivering longer service life and consistent performance.

Rock Drill Bit Hole Types

Rock drill bits create various types of holes, with the specific type depending on the application, drilling method, and geological conditions. The design of the drill bit itself, including its face shape and the arrangement of its carbide inserts, determines the kind of hole it will produce.

Here are some of the main types of holes created by rock drill bits:

- Blast Holes: These are a very common type of hole created in mining, quarrying, and construction. They are typically deep, large-diameter holes drilled to be filled with explosives. The goal is to clear large sections of rock efficiently for material extraction or site preparation.

- Anchoring/Bolt Holes: Smaller, more precise holes are drilled for installing rock bolts, anchors, or other support systems in tunnels, slopes, and underground excavations. These holes are critical for stabilizing rock formations and ensuring safety.

- Exploration Holes: These holes are drilled to collect geological data and rock samples. They can be full-face holes, or more commonly, “cored” holes, where a core bit drills a ring into the rock, leaving a cylindrical sample intact for analysis.

- Foundation/Piling Holes: Large-diameter holes are drilled for constructing foundations and structural supports in civil engineering projects. The size and depth of these holes are determined by the load-bearing requirements of the structure.

- Utility/Service Holes: Smaller holes are often drilled for utility lines, drainage, or other infrastructure purposes. These can range from simple, shallow holes to more complex, angled bores.

What is Drill Bit Flushing Hole Used for?

A drill bit flushing hole is a channel on the bit’s face that is used to effectively remove rock cuttings and debris from the borehole during drilling. This process, known as flushing, is critical for maintaining drilling efficiency and extending the life of the drill bit. By forcing a medium, such as compressed air or water, down the drill string and out through these holes, the drill bit clears the cuttings and prevents several common issues:

- Preventing Clogging: The flushing action clears debris, ensuring the cutting face of the bit remains exposed to the rock.

- Cooling the Bit: Friction from drilling generates immense heat. The flushing medium helps to cool the bit and prevent overheating, which can dull the cutting inserts and damage the bit body.

- Reducing Wear and Tear: By removing abrasive rock cuttings from the drilling zone, flushing reduces friction and wear on both the bit and the drill string.

- Improving Penetration Rate: A clear borehole allows the bit to maintain contact with fresh rock, leading to a faster and more consistent penetration rate.

- Preventing Sticking: Flushing helps to keep the bit from getting stuck in the borehole due to a buildup of rock cuttings.

What Types of Drill Bits are Designed with Flushing Holes?

Many types of drill bits are designed with flushing holes, as they are essential for efficient rock drilling. While the exact number and placement of these holes vary, they are a standard feature across a wide range of drill bits used in mining, construction, and quarrying.

Recommended Drill Bits with Flushing Holes

Here are some of the most common types of drill bits containing flushing holes:

- Button Drill Bits: These drill bits are popular in top hammer drilling and typically have two to three flushing holes. The holes are strategically placed between the carbide buttons to ensure that cuttings are quickly cleared from the bit face, maintaining high penetration rates.

- Tapered Drill Bits: Used with tapered drill rods, these drill bits come in various designs, including chisel, cross, and button drill bits. They almost always feature flushing holes to remove debris, a crucial function for preventing the drill bit from getting stuck in the borehole.

- Drag Drill Bits: While simpler in design than button drill bits, drag drill bits also rely on flushing holes. The holes are positioned to direct air or water over the blades, which helps to cool the drill bit and efficiently transport cuttings out of the hole, especially in softer rock.

- Tricone Drill Bits: Found in large-scale drilling operations, tricone drill bits feature multiple rollers. Flushing holes are essential on these drill bits, often located on the legs and body, to clean the cutting elements and evacuate large volumes of rock chips generated by the rolling action.

- Down-the-Hole (DTH) Drill Bits: These drill bits are designed for use with a DTH hammer. They feature multiple flushing holes on the bit face that work in tandem with the hammer’s air flow to both power the hammer and remove cuttings from the bottom of the deep hole.

- PDC Drill Bits: Polycrystalline Diamond Compact (PDC) drill bits, used extensively in oil and gas and geothermal drilling, are designed with intricate flushing channels. These channels direct the drilling fluid (mud) to cool the diamond cutters and carry away a large volume of cuttings efficiently.

How Many Flushing Holes for Drill Bits?

The number of flushing holes on a drill bit varies widely depending on the drill bit’s size, design, and intended application. There is no single standard number, as manufacturers engineer the flushing system to be as effective as possible for a specific use case.

Common configurations include:

- Two Holes: This is a very common design, especially for smaller to medium-sized bits. The two holes are typically placed symmetrically on the bit face to provide a balanced and effective flow.

- Three or More Holes: Larger bits, or those designed for very challenging or “sticky” rock formations, may have three, four, or even more flushing holes. This is done to ensure a more powerful and widespread flushing action, helping to remove larger volumes of cuttings and prevent blockages.

- Central Flushing Hole: Some bit designs incorporate a single, larger hole located in the center of the bit’s face. This is often seen in chisel or drag bits where a strong central jet of air or water is required to clear the cuttings.

- Internal Channels: In addition to external holes, some advanced bit designs feature internal channels or grooves on the skirt or body. These channels guide the flow of the flushing medium, ensuring that it reaches all parts of the bit face and the borehole to prevent debris buildup.

Common Drill Bit Flushing Hole Problems

Even with a well-designed flushing system, drill operators can encounter problems that hinder performance. Understanding these issues is key to effective troubleshooting and maintaining efficiency on the job.

1. Clogging of Flushing Holes:

The most common problem is when rock cuttings, mud, or other debris get packed into the flushing holes, restricting the flow of air or water. This leads to a significant drop in flushing power and can cause the bit to overheat and get stuck.

- Solution: Regularly check the bit for blockages. In some cases, a high-pressure air blast can dislodge the debris. For persistent issues, adjusting the drilling parameters, such as reducing the feed pressure or using a bit with larger flushing holes, can help.

2. Insufficient Flushing Pressure or Volume:

If the compressor or pump cannot provide enough pressure or volume, the flushing medium won’t have the force to effectively clear the cuttings. This can be caused by a worn-out pump, a leak in the drilling system, or simply using equipment that is not powerful enough for the application.

- Solution: Inspect the entire drilling system for leaks. Ensure your compressor or pump is correctly sized for the drilling depth and bit diameter. Regular maintenance of your equipment is crucial to prevent pressure drops.

3. Uneven or Misdirected Flow:

Sometimes, a flushing hole can become partially blocked or misaligned, causing the flushing medium to spray unevenly. This can lead to inefficient removal of cuttings from a specific area of the borehole, potentially causing the bit to stick or wear unevenly.

- Solution: Check the bit for damage to the flushing holes. If they are partially blocked, try to clean them. If the holes are a part of the original design, consider using a bit with a different flushing hole configuration that is better suited for your ground conditions.

By proactively addressing these common issues, operators can ensure their drill bits perform at their peak, reducing downtime and extending the life of their tools.

Conclusion

Mastering the use of drill bits with properly designed flushing holes is essential for any successful drilling operation. By ensuring efficient removal of rock cuttings, you can prevent costly blockages, reduce bit wear, and significantly increase your overall drilling speed. This seemingly small design feature has a massive impact on productivity, safety, and project cost-effectiveness.

As you plan your next drilling project, don’t underestimate the importance of a superior flushing system. Choosing a drill bit with an optimized flushing hole configuration can be the difference between a frustrating, slow job and a smooth, efficient one. It is a critical investment in both your equipment’s longevity and your team’s productivity.

For reliable, high-performance drill bits with expertly engineered flushing holes, look no further than Sinodrills. We offer a wide range of wholesale drill bits designed to meet the demands of any project. Contact us today to get a quote and equip your team with the best tools for the job.