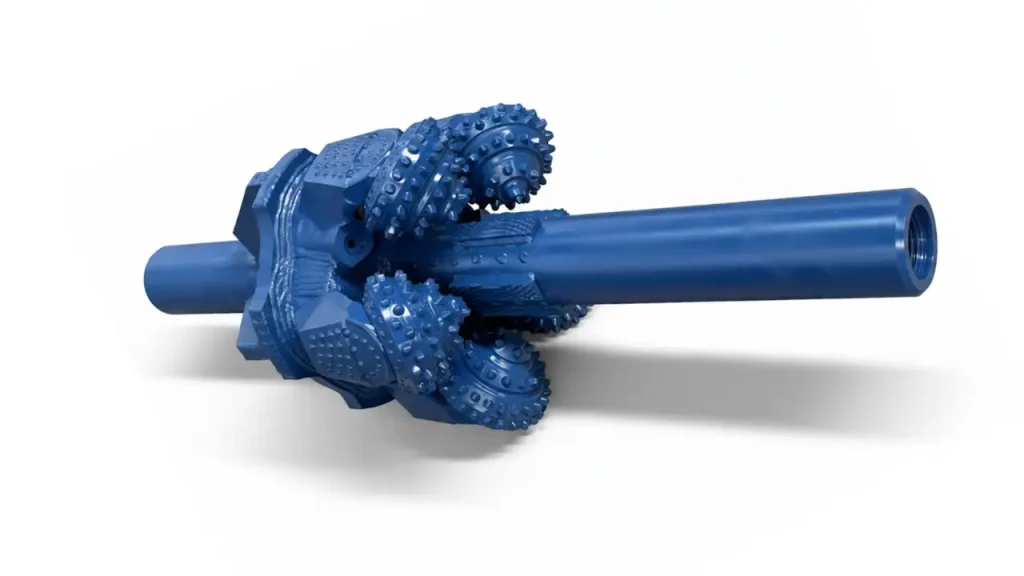

A reamer bit is a specialized drilling tool designed to enlarge and smooth existing holes in rock, soil, or other materials. Its precise cutting edges ensure consistent diameter and improved hole quality, making it essential for construction, mining, and engineering projects where accuracy and efficiency are critical.

Reamer bits come in various designs and sizes to suit different drilling applications. They help reduce wear on main drill bits, improve drilling stability, and optimize overall project performance. Understanding their functions and applications can help professionals choose the right tool for specific drilling needs.

What is a Reamer Bit?

A reamer bit is a specialized drilling tool used to enlarge, smooth, and accurately finish existing holes in materials like rock, soil, or concrete. Unlike standard drill bits that primarily create holes, reamer bits are designed to maintain a precise diameter, improve hole quality, and enhance overall drilling efficiency.

Reamer bits are commonly used in construction, mining, tunneling, and industrial applications. They help reduce wear on main drill bits, provide stability during drilling, and allow for better alignment of bolts, anchors, or casings. Available in various sizes and designs, reamer bits are essential for projects requiring precision and durability.

Types of Reaming Tools

Reaming tools come in various designs to suit specific drilling needs, materials, and hole sizes. Choosing the right type ensures precise hole enlargement, improved stability, and longer tool life. Below are five common types of reaming tools widely used in construction, mining, and industrial applications.

Shell Reamers

Shell reamers are cylindrical tools with cutting edges around their exterior. They are ideal for enlarging existing holes without changing the drill’s trajectory. Shell reamers provide smooth finishes and maintain accurate diameters, reducing the risk of misalignment during construction or mining operations.

These reamers are often used in large-diameter drilling applications. Their modular design allows easy replacement of cutting edges, enhancing durability and efficiency. They work well in both soft and hard rock environments, ensuring consistent performance over extended projects.

Rotary Reamers

Rotary reamers operate by rotating around the hole’s axis, gradually enlarging it to the desired size. They are commonly used in metalworking, tunneling, and foundation drilling. Rotary reamers ensure high precision and smooth hole surfaces, which is essential for alignment-sensitive projects.

They come in various sizes and configurations, allowing adaptation to different materials and hole diameters. These tools minimize vibration and wear on primary drill bits, providing cost-effective and reliable performance for repeated drilling tasks in construction and mining.

Expandable Reamers

Expandable reamers feature adjustable cutting heads, allowing flexibility in hole size. They are perfect for projects where variable diameters are required, offering efficiency and adaptability in drilling operations. Expandable reamers reduce the need for multiple tools, saving time and resources.

Their robust design ensures stability during drilling, preventing wobbling or uneven cuts. These tools are widely used in rock, soil, and concrete applications, providing accurate and smooth holes, especially in large-scale construction or industrial projects where precision is critical.

Taper Reamers

Taper reamers are designed to create or enlarge tapered holes for fasteners, anchors, or machine parts. They gradually widen the hole from one end to the other, ensuring precise fits. These tools are essential for engineering and mechanical applications where exact taper angles are required.

They provide clean, accurate cuts with minimal material stress. Taper reamers are used in both metal and construction projects, allowing easy assembly of components and ensuring proper alignment and stability in the finished structure.

Machine Reamers

Machine reamers are designed for use with drilling machines or lathes to achieve precise hole diameters. They are highly accurate and provide smooth finishes, making them suitable for industrial and mechanical operations requiring tight tolerances.

These reamers come in various configurations, including straight, spiral, and adjustable types. Machine reamers help reduce manual labor, improve consistency, and extend the life of other drilling tools by minimizing stress on the primary cutting equipment.

How to Use a Reamer Bit?

Using a reamer bit correctly ensures precise hole enlargement, smooth finishes, and longer tool life. Following proper steps prevents damage to the bit and the workpiece, enhancing efficiency and accuracy for construction, mining, and industrial drilling projects.

Step 1: Select the Right Reamer Bit

Choosing the correct reamer bit for your material and hole size is critical. Consider diameter, type, and cutting edge design to match your drilling requirements. Using the wrong bit can result in poor hole quality and increased wear on equipment.

Ensure compatibility with your drill or machine. Check the material hardness and hole depth to avoid overloading the reamer. Proper selection minimizes vibration, reduces cutting resistance, and guarantees smooth, precise results for efficient drilling performance.

Step 2: Prepare the Hole and Equipment

Before using the reamer bit, ensure the existing hole is clean and free of debris. Verify that your drill or machine is secure and properly aligned with the hole for accurate reaming. Safety equipment should be worn.

Check lubrication and cooling if required, as these reduce heat buildup and extend the life of the reamer bit. Proper preparation ensures stable operation, prevents tool breakage, and allows the reamer to create consistent, precise holes with minimal effort.

Step 3: Ream the Hole

Insert the reamer bit into the hole and apply steady, controlled pressure. Rotate the bit at the recommended speed, allowing it to gradually enlarge the hole without forcing it, which could damage both the bit and the material.

Maintain alignment and consistent feed rate throughout the operation. Regularly withdraw the reamer to clear chips and debris. This technique prevents jamming, ensures smooth cuts, and achieves the desired hole diameter and finish efficiently and safely.

Step 4: Inspect and Finish

After reaming, remove the bit and inspect the hole for accuracy, diameter, and surface finish. Make any adjustments or minor passes if needed to achieve the desired result. Proper inspection ensures quality and reliability.

Clean the reamer bit and store it properly to maintain sharpness and durability. Accurate inspection and maintenance prevent premature wear, extend tool life, and guarantee consistent performance for future projects, making reaming operations safe and effective.

Why Choose Our Reamer Bits?

Our reamer bits are engineered for precision, durability, and efficiency, ensuring smooth hole enlargement for construction, mining, and industrial applications. Choosing the right reamer bit can save time, reduce equipment wear, and improve overall project performance, making our products a reliable choice.

- Durable Construction: We use high-quality materials and advanced manufacturing techniques to ensure our reamer bits withstand heavy use and harsh conditions, minimizing tool replacement, reducing downtime, and providing consistent performance for repeated drilling tasks.

- Precision and Accuracy: Our reamer bits maintain exact diameters and smooth finishes, ensuring accurate hole enlargement, proper alignment of anchors or bolts, and consistent professional-grade results across all drilling applications.

- Versatile Applications: We offer various reamer bit types and sizes suitable for rock, concrete, and soil, allowing contractors and engineers to use a single supplier for multiple projects, simplifying procurement and improving operational efficiency.

- Optimized Performance: Our reamer bits reduce vibration, cutting resistance, and wear on primary drill bits, enhancing drilling efficiency, prolonging tool life, and ensuring smoother operation for faster, safer, and cost-effective projects.

- Reliable Support: We provide technical guidance, product selection advice, and prompt customer service, helping users maximize performance, longevity, and value of every reamer bit purchased.

Conclusion

Reamer bits are indispensable tools for achieving precise hole enlargement and maintaining drilling efficiency. They enhance project accuracy while protecting primary drill bits, making them a cost-effective solution for construction, mining, and industrial applications.

At Sinodrills, we offer a wide range of high-performance reamer bits to meet diverse drilling requirements. Our products are built to deliver durability, reliability, and superior performance for every project.

For those looking to purchase in bulk, get wholesale reamer bits from Sinodrills. We provide competitive pricing, fast delivery, and professional support to ensure your drilling projects run smoothly and efficiently.