When considering a private water source, two common options emerge: bored wells and drilled wells. While both aim to tap into underground aquifers, their construction methods, typical depths, and suitability for various applications differ significantly. Understanding these distinctions is crucial for making an informed decision for your water supply.

This guide will delve into the fundamental differences between bored wells and drilled wells. We’ll explore how each type is constructed, the typical water sources they access, their respective advantages and disadvantages, and which option might be best suited for your specific needs, whether for domestic use or agricultural irrigation.

What is Bored Well?

A bored well is a type of water well constructed by excavating a relatively wide, shallow hole into the ground, typically using a large auger.

Unlike drilled wells that penetrate deep into bedrock, bored wells primarily access water from the shallower water table and unconsolidated materials like sand, gravel, and clay, usually not exceeding 100 feet in depth.

They are often lined with concrete tiles or other materials to prevent collapse and are more susceptible to fluctuations in the water table and potential contamination from surface runoff compared to deeper, more protected drilled wells.

Bored Well Drilling Tools Needed

Bored well drilling, while less complex than deep well drilling, still requires specific tools designed for excavating wide, shallow holes in unconsolidated formations. These tools are primarily focused on efficient material removal and maintaining the stability of the borehole during the digging process. The selection of tools often depends on the specific soil conditions encountered at the site in Qingdao.

- Auger Bits: These are the primary digging tools for bored wells. They come in various diameters to create the wide bore, and their helical blades are designed to efficiently scoop and lift loose soil, sand, and gravel to the surface.

- Crane or Excavator with Auger Attachment: A heavy-duty crane or excavator serves as the main machinery, providing the power and lifting capacity to operate the large auger bits and remove excavated material.

- Casing or Liner (e.g., Concrete Culverts, Large Diameter PVC Pipe): These materials are crucial for lining the bored well to prevent the walls from collapsing, especially in loose or unstable soil conditions, and to help filter water.

- Tripod and Winch System: For manual or semi-manual bored well digging, a robust tripod and winch system can be used to lift and lower the auger and excavated material.

- Hand Tools (Shovels, Picks): Often used for initial ground preparation, clearing debris, and fine-tuning the well bottom after the main auger work is complete.

- Water Pumps: Necessary for dewatering the well during construction if the water table is encountered, or for testing the well’s yield once complete.

What is Drilled Well?

A drilled well is a type of water well created by boring a relatively narrow hole deep into the ground using specialized drilling equipment.

Unlike shallower bored or dug wells, drilled wells can penetrate hundreds or even thousands of feet to access deeper aquifers, often those located within bedrock.

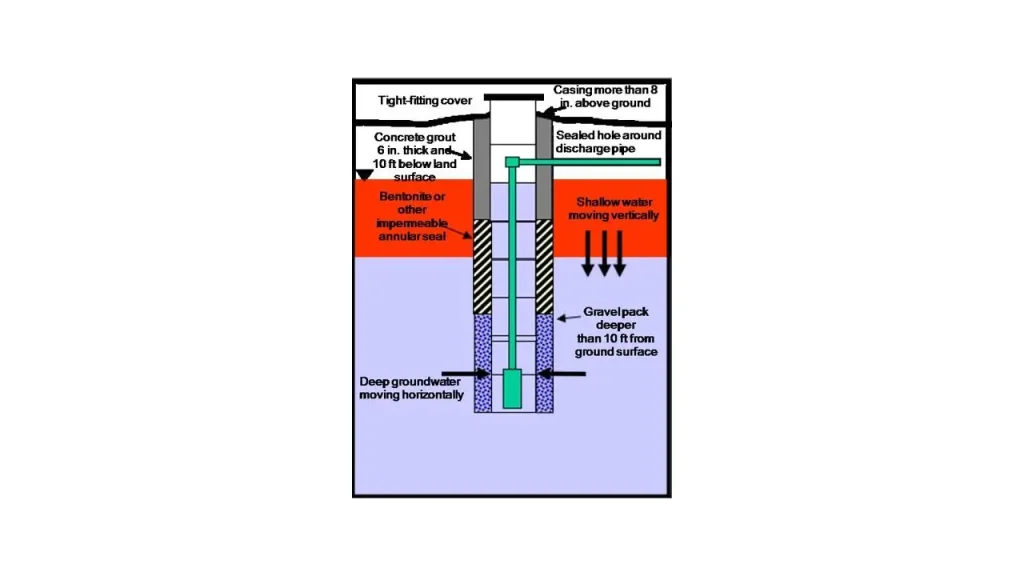

This method provides a more reliable and consistent water supply, as deeper aquifers are typically less susceptible to seasonal fluctuations in the water table and are better protected from surface contamination. Drilled wells are typically lined with a durable casing and sealed with grout to ensure the integrity of the borehole and prevent pollutants from entering the water source.

Drilled Well Drilling Tools Needed

Recommended Well Drilling Tools

Drilled well drilling requires a specialized and robust set of tools designed to penetrate various geological formations, often reaching significant depths. The specific tools utilized depend heavily on the chosen drilling method (rotary, air rotary, cable tool) and the type of rock and soil encountered. These tools are engineered for high performance, durability, and precision to ensure the successful creation of a stable and productive deep well.

- Drilling Rig: This is the core piece of equipment, providing the power to rotate the drill string and bits, and to lift and lower casing. Rigs can be truck-mounted for mobility or crawler-mounted for stability on rough terrain, essential for various sites in Qingdao.

- Drill Pipe/Drill Rods: These heavy-duty steel pipes are connected together to form the drill string, transmitting rotational force and drilling fluid/air to the drill bit at the bottom of the borehole. Their strength and durability are critical for deep penetration.

- Drill Bits: As discussed previously, specialized bits like tricone, PDC, drag, or DTH hammer bits are used to cut through different rock types. The choice is crucial for efficient penetration and longevity, adapting to Qingdao’s varied geology.

- Drilling Fluids (Mud or Air): Drilling mud (a mixture of water, clay, and additives) or compressed air is circulated down the drill string to cool the bit, lubric lubricate it, and carry rock cuttings to the surface, maintaining borehole stability.

- Well Casing: Steel or PVC pipes inserted into the borehole to prevent collapse, isolate water-bearing zones, and ensure the integrity of the well. Its selection depends on depth, formation, and water quality requirements.

- Well Screen: A specialized section of casing with slots or perforations, placed at the aquifer level. It allows water to enter the well while keeping out sand, gravel, and other particulate matter, crucial for clean water in Qingdao.

- Grout Mixer and Pump: Used to mix and pump grout (typically cement or bentonite) into the annular space between the casing and the borehole wall. This creates a sanitary seal, preventing surface contamination from entering the well.

- Submersible Pump and Accessories: Once the well is completed, a submersible pump is installed to draw water from the well to the surface. This includes the pump itself, motor, electrical wiring, and a pressure tank for water storage and delivery. Drilled well construction demands a sophisticated array of specialized tools and machinery to penetrate deep into various geological formations, common in areas like Qingdao, China. These tools are designed for efficiency, durability, and precision, ensuring the successful creation of a long-lasting and reliable water source. The specific equipment used can vary depending on the chosen drilling method and the nature of the subsurface.

The investment in high-quality drilling tools is critical for deep wells, as they must withstand immense pressure, abrasion, and often extreme temperatures. Proper maintenance and skilled operation of these tools are paramount to the success, safety, and cost-effectiveness of any deep well drilling project.

- Drilling Rig: This is the central piece of equipment, providing the power and mechanism to rotate the drill string and apply downward force. Rigs come in various types (e.g., rotary, air rotary, cable tool), chosen based on the geology and desired well depth, like those used to penetrate hard rock in Qingdao.

- Drill Pipe/Drill Rods: These are heavy-duty steel pipes that connect the drilling rig to the drill bit. They transmit rotational force and drilling fluid down the borehole, extending in sections as the well deepens.

- Drill Bits: As discussed previously, these are the cutting tools at the very end of the drill string. Types include tricone roller bits, PDC bits, drag bits, and DTH (Down-the-Hole) hammer bits, each designed for specific rock and soil conditions encountered during drilling.

- Air Compressor: Essential for air rotary drilling and DTH hammer operations. The compressor provides high-pressure air that powers the DTH hammer and carries rock cuttings up the borehole to the surface, efficiently clearing the well.

- Mud Pump and Drilling Fluids (Mud): Used in rotary drilling, the mud pump circulates drilling fluid (a mixture of water, clay, and additives) down the drill pipe. This fluid cools and lubricates the drill bit, stabilizes the borehole, and transports cuttings to the surface.

- Well Casing and Screen: Durable pipes (steel or PVC) that are lowered into the borehole to prevent collapse and isolate the water-bearing aquifer. The well screen, a perforated section, allows water to enter while keeping out sediment.

- Grout and Grouting Equipment: Grout, typically a cement mixture, is pumped into the annular space (the gap between the casing and the borehole wall) to create a sanitary seal, preventing contamination from surface water or shallower aquifers.

- Bailers: Used to remove water and fine sediments from the well during development or for collecting water samples for quality testing. They are typically long, cylindrical containers with a check valve at the bottom.

- Fishing Tools: In the event of a lost drill bit or broken drill pipe in the borehole, specialized “fishing” tools are used to retrieve the lost equipment, preventing costly project delays.

Bored Well vs Drilled Well

Choosing between a bored well and a drilled well involves understanding their fundamental differences in construction, depth, water access, and long-term performance. Each type offers distinct advantages and disadvantages depending on your specific needs and local geology.

Construction Method

Bored wells are constructed using a large auger or excavation equipment, creating a wide, relatively shallow hole. This method is suitable for unconsolidated formations like sand, gravel, and clay, where the water table is close to the surface.

Drilled wells, on the other hand, utilize specialized drilling rigs that bore a narrow hole deep into the ground, often penetrating bedrock. This method is necessary when accessing deeper, more stable aquifers.

Depth and Water Source

Bored wells typically draw water from shallow, unconfined aquifers, usually reaching depths of up to 100 feet. Their water source is more susceptible to seasonal variations in the water table and surface influences.

Drilled wells access deeper, confined aquifers, often extending hundreds or even thousands of feet. This provides a more consistent and reliable water supply, less affected by surface conditions or short-term climatic changes.

Water Quality and Contamination

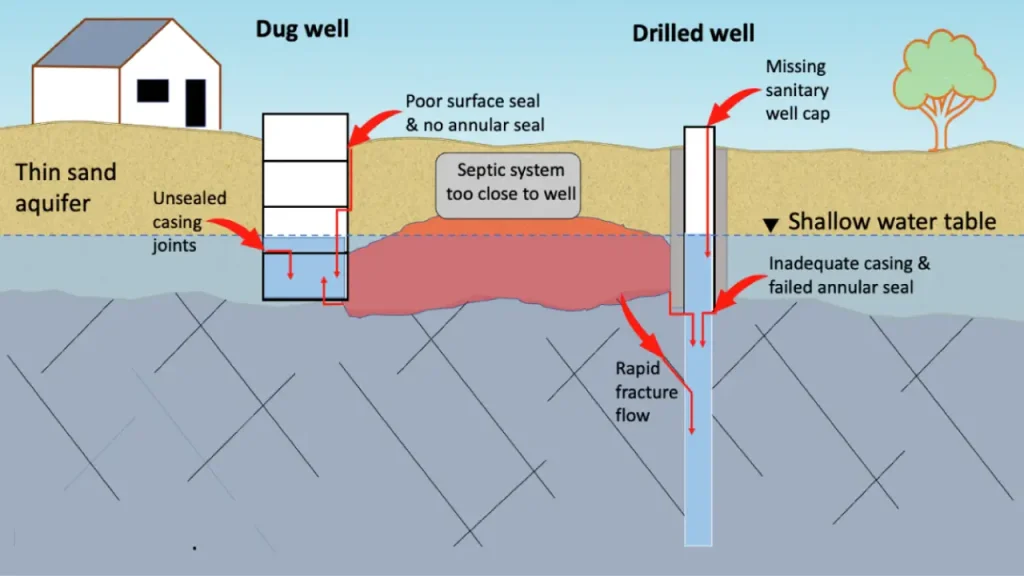

Water from bored wells is generally more vulnerable to contamination from surface runoff, agricultural pollutants, and septic systems due to their shallower depth and wider opening. Regular testing and maintenance are crucial.

Drilled wells offer better protection against surface contaminants because of their depth, narrower diameter, and the sealing provided by casing and grout. This often results in higher quality, safer drinking water.

Cost and Installation Time

Bored wells generally have lower initial drilling costs due to simpler equipment and shallower depths. The installation time is also typically shorter, making them a quicker solution for immediate water needs.

Drilled wells are usually more expensive to install due to the specialized equipment, longer drilling times, and higher labor costs associated with penetrating harder rock formations and greater depths.

Well Drilling Bits Needed

For bored wells, large auger bits are primarily used to excavate wide holes in softer soils and unconsolidated materials. These bits are designed for efficient material removal rather than rock penetration.

Drilled wells require a variety of specialized well drilling bits, depending on the geological conditions. These can include tricone roller bits for various rock types, PDC bits for softer to medium-hard formations, drag bits for very soft materials, and DTH (Down-the-Hole) hammer bits for extremely hard rock.

Comparison Table: Bored Well vs. Drilled Well

| Feature | Bored Well | Drilled Well |

| Construction Method | Large auger/excavation | Rotary, Air Rotary, Cable Tool rigs |

| Typical Depth | Shallow (up to 100 feet) | Deep (hundreds to thousands of feet) |

| Water Source | Shallow, unconfined aquifers | Deep, confined aquifers |

| Water Quality Risk | Higher susceptibility to surface contamination | Lower susceptibility to surface contamination |

| Initial Cost | Generally lower | Generally higher |

| Reliability | More prone to seasonal fluctuations | More consistent and reliable |

| Well Drilling Bits | Large auger bits | Tricone, PDC, Drag, DTH Hammer bits |

How to Choose Bore and Drilled Well

Choosing between a bored well and a drilled well requires a careful evaluation of several critical factors. The best choice depends significantly on the specific geological conditions of your property in Qingdao, China, your expected water usage, and your budget constraints. Understanding these elements will help you make an informed decision for a reliable water supply.

It’s highly recommended to consult with a local hydrogeologist or experienced well drilling contractor. They can conduct a site-specific assessment, providing valuable insights into the subsurface conditions and recommending the most suitable well type for your long-term water needs.

- Geological Conditions:If your property consists primarily of soft soils, sand, or gravel with a shallow water table, a bored well might be a cost-effective solution. However, if hard rock or deep, stable aquifers are present, a drilled well is essential for proper penetration and access.

- Water Table Depth:Bored wells are suitable for areas where the water table is consistently shallow, typically less than 100 feet deep. If the water table is deep or fluctuates significantly with seasons, a drilled well is necessary to ensure a consistent water supply.

- Desired Water Quantity and Quality:For high water demand (e.g., irrigation, multiple households) or if high water quality is paramount, a drilled well reaching deeper, confined aquifers is generally superior. Bored wells, being shallower, can be more susceptible to surface contamination and have lower yields.

- Budget and Long-Term Costs:Bored wells often have lower initial construction costs due to simpler equipment and shallower depths. However, considering potential future costs for water treatment or deepening if the water table drops, a drilled well’s higher upfront investment might lead to lower long-term expenses.

- Risk of Contamination:If your property is near potential sources of surface contamination (e.g., agricultural runoff, septic systems), a drilled well offers better protection due to its depth and the sealed casing. Bored wells, being shallower and wider, have a higher inherent risk of contamination.

Conclusion

Choosing between a bored well and a drilled well requires a thorough understanding of their fundamental differences. Bored wells, typically shallower and wider, are suited for areas with high water tables and unconsolidated materials. They are generally less expensive to construct but more susceptible to surface contamination and seasonal water fluctuations.

Drilled wells, conversely, can reach much deeper into bedrock, offering a more stable and often purer water supply. While initially more expensive due to specialized equipment and expertise required, they provide greater reliability and protection from contaminants, making them a superior long-term investment for consistent water needs.

Ultimately, the best choice depends on your specific geological conditions, water demand, and budget. For any well drilling project, ensuring you have the right tools is paramount. Get wholesale well drilling tools from our Sinodrills to guarantee efficiency and quality for your project.