Choosing the right drill bit shank is crucial for achieving precision and efficiency in any drilling project. Drill bit shank types vary in shape and design, each offering unique benefits depending on the material, drill type, and application. Understanding these differences ensures better performance and longer tool life.

From round and hex shanks to SDS and tapered designs, each drill bit shank type serves a specific purpose. Selecting the proper shank improves stability, reduces slippage, and enhances safety during operation. Whether for metal, wood, or concrete, knowing which shank type to use simplifies your drilling tasks and saves time.

What is Drill Bit Shank?

A drill bit shank for rock drilling is the part of the drill bit that connects to the drill machine or hammer. It acts as the interface between the drill and the power source, transferring torque and impact force directly to the drill bit tip. The shank design ensures stability, reduces slippage, and allows efficient drilling into hard materials like rock or concrete.

Different shank types are used in rock drilling depending on the drill system and application. Common designs include round shanks, hex shanks, SDS shanks, and tapered shanks. Each type provides a specific fit, enhances performance, and ensures safety during operation. Choosing the correct shank type is crucial for achieving precise, efficient, and durable drilling results.

What is a Shank in Mining?

In mining, a shank is the rear portion of a drilling tool that connects the drill bit to the drilling machine or drill rod.

It transmits impact energy, rotation, and thrust from the drill to the bit. Proper shank design ensures secure connection, efficient power transfer, reduced vibration, and reliable performance during rock drilling operations.

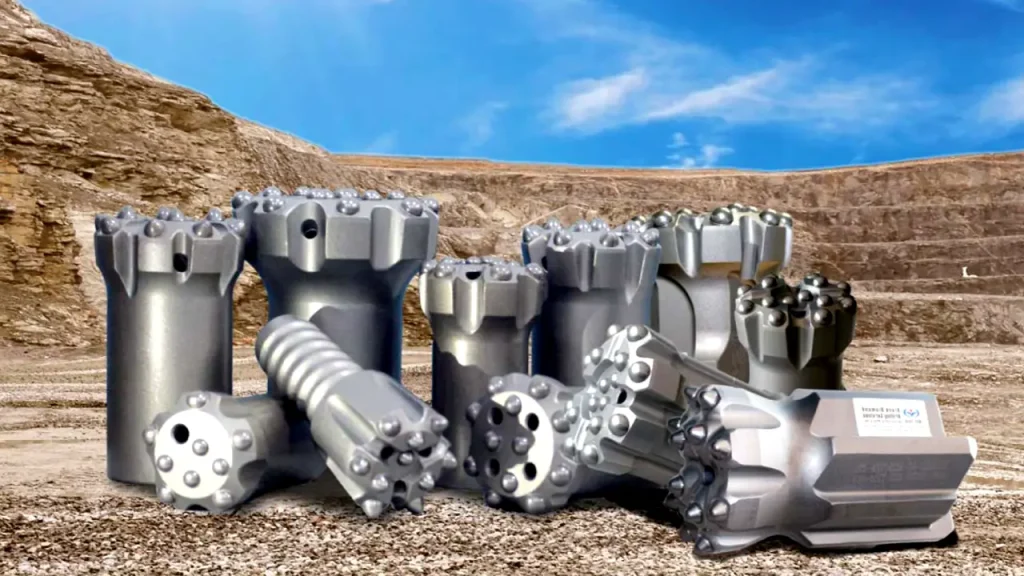

Drill Bit Shank Types

Drill bits are essential tools in various industries, from construction to mining. The performance and efficiency of a drill bit largely depend on its shank type, which is the part that fits into the drilling machine. Different shank designs are engineered to suit specific drilling applications, ensuring optimal power transfer, stability, and durability. Understanding these types is crucial for selecting the right tool for the job.

The choice of drill bit shank can significantly impact drilling speed, accuracy, and the lifespan of both the bit and the drilling equipment. Factors such as the material being drilled, the type of drilling machine, and the required depth all play a role in determining the most suitable shank. Incorrect selection can lead to premature wear, breakage, and inefficient drilling operations.

Tapered Shanks

Tapered shanks are characterized by a conical shape that allows them to fit snugly into a matching tapered bore in the drilling machine spindle. This design relies on friction for secure gripping, eliminating the need for chucks or collets. They are commonly found on larger drill bits and are ideal for applications where high torque and precise alignment are necessary.

The absence of a chuck in tapered shanks reduces potential points of failure and minimizes run-out, which contributes to greater drilling accuracy. While they offer excellent stability and concentricity, tapered shanks require careful handling and maintenance to ensure a clean, damage-free taper for optimal performance.

Straight Shanks

Straight shanks are the most common type, featuring a cylindrical body that is typically held in a drill chuck. Their simplicity and versatility make them suitable for a wide range of drilling tasks, from small handheld drills to larger industrial machines. They come in various diameters, allowing for flexibility in bit size.

These shanks are easy to install and remove, making them convenient for quick bit changes. However, the gripping force of the chuck is crucial for preventing slippage, especially during high-torque applications. Over-tightening or insufficient tightening of the chuck can lead to damage to the shank or inaccurate drilling.

Hex Shanks

Hex shanks have a hexagonal cross-section, which provides a strong, non-slip grip in quick-change chucks. This design is particularly popular in cordless drills and impact drivers, where rapid bit changes and resistance to cam-out are highly valued. The flat sides of the hexagon prevent the bit from rotating independently within the chuck.

The hexagonal shape ensures excellent torque transfer, making them well-suited for demanding applications that involve significant rotational force. While highly efficient for quick changes and robust performance, hex shanks are generally limited to specific chuck types designed to accommodate their shape.

SDS Shanks

SDS (Slotted Drive Shaft) shanks are designed for hammer drills and rotary hammers, featuring indentations and slots that allow the bit to slide freely within the chuck while still maintaining a secure drive. This design enables the hammering action characteristic of these powerful tools, making them highly effective for drilling into masonry and concrete.

The unique design of SDS shanks allows for both rotary and hammering action to be transmitted effectively, significantly improving drilling efficiency in tough materials. They are also designed for quick and easy insertion and removal, enhancing user convenience and productivity in demanding construction environments.

Here are different type of shank in the following:

| Shank Type | Description | Common Applications | Advantages | Disadvantages |

| Tapered Shanks | Conical shape, fits directly into spindle taper. | Larger drilling machines, precision work | High accuracy, strong grip without chuck | Requires clean taper, not quick-change |

| Straight Shanks | Cylindrical body, held by a drill chuck. | Handheld drills, general purpose drilling | Versatile, easy to use, wide size range | Can slip if chuck is not tight enough |

| Hex Shanks | Hexagonal cross-section, fits quick-change chucks. | Cordless drills, impact drivers, driving bits | Non-slip grip, quick changes, high torque transfer | Requires hex-compatible chuck |

| SDS Shanks | Slotted drive shaft, designed for hammer and rotary hammers. | Masonry, concrete drilling, construction | Efficient hammering, quick changes, secure grip | Specific to hammer/rotary drill chucks |

Hammer Drill Bit Shank Types

Rock hammer drill bit shank types determine how bits connect to hammers, affecting energy transfer, efficiency, and compatibility. Different shank designs are used depending on drilling depth, hammer size, and rock hardness. Choosing the right shank ensures optimal performance, reduced wear, and consistent penetration rates across various rock formations.

- QL Shank Type – The QL shank type features a precise alignment for efficient energy transfer between the hammer and bit. It offers durability, improved flushing efficiency, and better hole straightness. Commonly used in mining and quarrying, it provides excellent stability and longer service life under heavy-duty drilling operations.

- Mission Shank Type – Mission shanks are engineered with a strong coupling system that resists deformation and stress fatigue. They ensure steady impact energy delivery for deeper hole drilling. Ideal for large-scale mining, foundation, and geothermal projects, Mission shanks balance power with reliability in hard and abrasive rock conditions.

- DHD Shank Type – DHD shank types are widely adopted due to their compatibility with multiple hammer designs. They provide efficient air distribution and high impact power for superior penetration rates. Known for versatility, DHD shanks are perfect for quarrying, construction, and water well drilling in medium to hard formations.

- SD Shank Type – The SD shank type delivers balanced impact distribution, minimizing stress concentration at the coupling point. It enhances bit stability and operational precision. Frequently used in deep-hole and blast-hole drilling, SD shanks ensure excellent reliability, smooth performance, and reduced risk of misalignment or bit breakage during long runs.

- COP Shank Type – COP shanks are designed for extreme drilling conditions where high impact and penetration rates are critical. They provide secure hammer-bit connection and uniform energy transmission. This shank type reduces vibration, extends tool life, and ensures stable performance in demanding mining and construction drilling environments.

Rock Drill Bit Shank Lengths

Choosing the right shank length for rock drill bits is essential for drilling efficiency and safety. Shank length affects bit stability, reach, and compatibility with drilling equipment. Understanding the differences between long and short shanks helps optimize drilling performance in various rock conditions.

- Long Shank Drill Bits – Long shanks provide extended reach for deep or hard-to-access drilling locations. They reduce the need for repositioning equipment, maintain better alignment in deep holes, and enhance penetration rates. Long shanks are ideal for underground or benching applications where depth is critical.

- Short Shank Drill Bits – Short shanks are suitable for shallow holes or surface drilling projects. They offer greater rigidity, reduce vibration, and improve precision in confined drilling areas. Short shanks are easier to handle, require less torque, and are preferred for quick or repetitive drilling tasks.

- Compatibility with Equipment – The chosen shank length must match the drill machine’s chuck and feed system. Long shanks may require extended drill rods or specialized adapters, while short shanks work efficiently with standard rigs, ensuring proper force transfer and minimizing wear on the equipment.

- Operational Considerations – Long shanks can increase torque demands and may bend under excessive load, while short shanks offer better control and less flex. Selecting the correct shank length balances drilling depth, bit stability, and operator safety, preventing delays and costly equipment damage.

- Project-Specific Needs – Shank length should match the drilling project requirements, including hole depth, rock hardness, and accessibility. Evaluating these factors ensures optimal bit performance, reduces maintenance, and increases overall drilling efficiency, whether for exploration, construction, or mining operations.

How to Choose Suitable Drill Bits?

Choosing the right drill bits for rock drilling is crucial for efficiency, precision, and safety. Different rock types, drilling conditions, and equipment require specific drill bit designs. Selecting the appropriate bit ensures longer service life, faster drilling, and lower operational costs.

- Rock Type Consideration – Hard, medium, or soft rock requires drill bits with different tip designs, materials, and coatings. Matching the bit to the rock type prevents excessive wear and improves penetration rates, ensuring stable and effective drilling throughout the project.

- Shank Type Selection – Drill bit shanks vary, including straight, tapered, and threaded types. The shank must fit the drilling machine securely. A proper shank type minimizes vibration, enhances bit stability, and allows smooth rotation, improving drilling precision and overall efficiency.

- Bit Material – Drill bits come in steel, tungsten carbide, and composite options. The material affects durability, heat resistance, and cutting performance. Choosing a material suited to the drilling environment reduces breakage and maintenance frequency, saving costs over time.

- Drilling Method – Rotary, percussive, or rotary-percussive drilling requires specific bit designs. Using the correct method-compatible bit ensures efficient energy transfer, faster rock penetration, and less wear. This selection is essential for optimizing drilling productivity and project timelines.

- Bit Size and Diameter – The hole size determines the bit diameter needed. Choosing the correct size ensures proper hole formation, minimizes rock fracturing, and supports accurate installation of anchors, bolts, or casing. Oversized or undersized bits can compromise safety and project quality.

Conclusion

In summary, understanding drill bit shank types is essential for both professionals and DIY enthusiasts. The right shank improves drilling efficiency, tool longevity, and overall safety. By considering the material, drill type, and application, you can select the ideal shank for any project.

For projects requiring heavy-duty drilling, having access to a variety of shank types is key. Sinodrills offers a wide selection of wholesale rock drill bits with different shank designs, ensuring you find the perfect fit for every job. Our range supports diverse drilling needs and industrial applications.

By choosing Sinodrills for your drill bit supply, you gain reliable options that meet professional standards. Explore our inventory to find round, hex, SDS, and tapered shank bits, all designed to maximize efficiency and precision in your drilling operations.