The journey of extracting natural gas from deep within the earth is a testament to human ingenuity, transforming solid rock into a vital energy resource. At the heart of this complex process lies the humble yet incredibly sophisticated drill bit. Its design and performance are paramount, directly impacting the efficiency, cost, and overall success of gas well drilling operations.

This blog post will delve into the critical role of drill bits in the gas well drilling process. We’ll explore how technological advancements in drill bit design and materials are optimizing performance, reducing drilling time, and ultimately making the journey from rock to resource more efficient and economically viable for the energy industry.

What is Gas Well Drilling

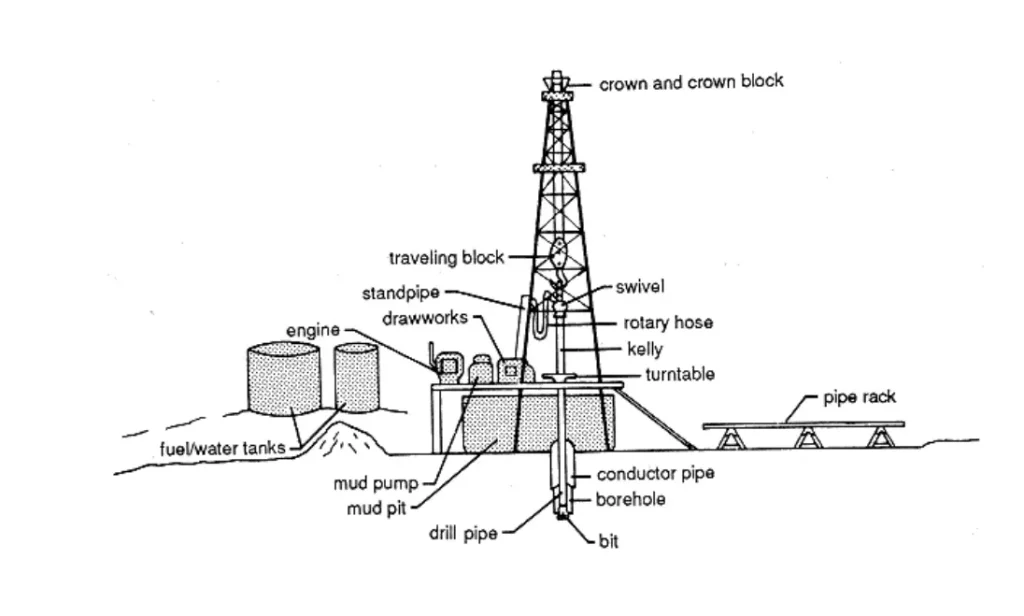

Gas well drilling is a complex engineering process involving the creation of a borehole deep into the Earth’s crust to access and extract natural gas reserves. This involves using specialized drilling rigs that rotate a drill string with a cutting drill bit at its end, penetrating various rock formations. As the hole is drilled, a circulating “drilling mud” cools the bit, carries rock cuttings to the surface, and helps maintain wellbore stability and control subsurface pressures.

Once the target gas-bearing formation is reached, steel casing pipes are inserted and cemented into the wellbore to prevent collapse and isolate different geological layers, ensuring the safe and efficient flow of natural gas to the surface. The entire process, from site preparation and well design to drilling, casing, and eventually well completion, is meticulously planned and executed to maximize gas recovery while adhering to stringent safety and environmental regulations.

Can You Drill Your Own Natural Gas Well?

While the idea of drilling your own natural gas well for personal use might seem appealing for energy independence, it’s generally not a practical or legally simple undertaking for the average individual.

The process of gas well drilling is highly complex, requiring specialized heavy machinery, advanced geological expertise, significant capital investment (as outlined in the previous response), and adherence to a vast array of stringent federal, state, and local regulations.

These regulations cover everything from permitting, well construction and safety standards (including blowout prevention), environmental protection, and eventual well abandonment, all designed to ensure public safety and minimize environmental impact. Even where “home use” wells are permitted, they typically involve strict licensing, ongoing compliance, and a high degree of responsibility that far exceeds a typical homeowner’s capabilities or resources.

Why Gas Well Drilling

Gas well drilling is a fundamental process driven by the world’s increasing demand for energy. It allows us to access crucial natural gas reserves, which offer several compelling advantages:

- Clean Energy Source: Natural gas burns more cleanly than other fossil fuels, producing significantly less carbon dioxide and other pollutants. This makes it a vital transitional fuel as the world moves towards a more sustainable energy future.

- Versatile Applications: Natural gas is incredibly versatile, used not only for electricity generation but also for heating homes, as a feedstock in various industrial processes, and even as a transportation fuel, powering vehicles and contributing to diverse economic sectors.

- Energy Security: Domestic gas well drilling reduces reliance on foreign energy imports, enhancing a nation’s energy independence and economic stability. This ensures a reliable and secure supply for residential, commercial, and industrial needs, minimizing vulnerability to geopolitical fluctuations.

- Economic Benefits: The gas well drilling industry creates numerous jobs, from engineers and geologists to rig operators and support staff. It also generates substantial tax revenues and stimulates local economies through infrastructure development and service demands, fostering regional growth.

Drill Bits for Gas Well Drilling

Recommended Drill Bits for Gas Well Drilling

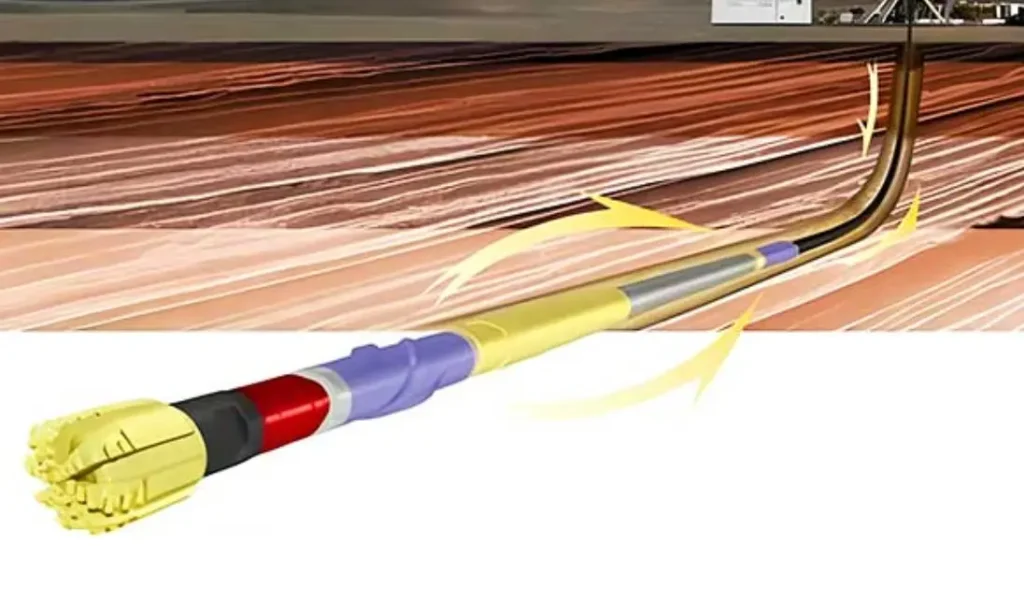

Choosing the right drill bit is paramount for efficient and cost-effective gas well drilling, as different geological formations require specific cutting mechanisms. The widely used drill bits are designed to optimize penetration rates and extend bit life across varying rock hardness and abrasiveness.

- Roller Cone Bits (Tricone Bits): These bits feature three rotating cones with either milled steel teeth or tungsten carbide inserts (TCI). Milled tooth bits are ideal for softer, less abrasive formations by gouging and scraping, while TCI bits, with their harder inserts, are excellent for crushing and fracturing medium to hard, abrasive rock formations.

- PDC (Polycrystalline Diamond Compact) Bits: Fixed cutter bits with no moving parts, PDC bits utilize synthetic diamond cutters to shear rock. They are highly effective in homogeneous, soft to medium-hard formations, offering superior rates of penetration and extended bit life, especially in shales and carbonates.

- Natural Diamond Bits: While less common than PDC bits, natural diamond bits are used for extremely hard and abrasive formations where other bit types struggle. They operate by grinding the rock and are particularly effective in deep, high-temperature wells or for coring operations where formation samples are needed.

- Hybrid Drill Bits: These innovative bits combine the strengths of both roller cone and PDC technologies. They feature a combination of rolling cones and fixed PDC cutters, allowing them to adapt to mixed or interbedded formations, providing both impact resistance and high cutting efficiency.

How Long Does It Take to Drill a Gas Well?

The time it takes to drill a natural gas well can vary significantly, ranging from a few weeks to several months, or even over a year for extremely complex projects. This timeframe is influenced by a multitude of factors, with no two wells being exactly alike. The actual drilling phase is often just one component of the overall timeline, which also includes site preparation, well completion, and testing.

Here are the key factors that determine how long it takes to drill a gas well:

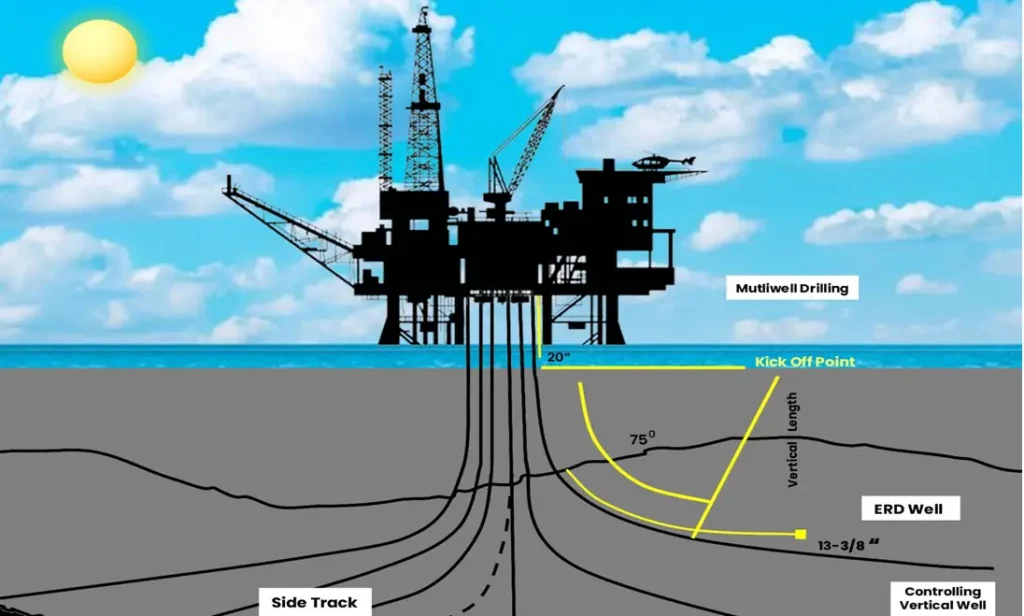

- Well Depth and Design: Deeper wells naturally take longer to drill. Horizontal wells, which involve drilling vertically to a certain depth and then turning to drill horizontally through the gas-bearing formation, add considerable complexity and time compared to simpler vertical wells.

- Geological Formations: Encountering hard, abrasive rock, unstable formations, or high-pressure zones can slow drilling progress significantly. These conditions may require specialized drill bits, slower penetration rates, and additional procedures to maintain wellbore stability and control.

- Location and Accessibility: Wells in remote, challenging terrains or offshore environments require more time for rig mobilization, logistics, and often face weather-related delays, all of which extend the overall timeline.

- Drilling Performance and Efficiency: The performance of the drilling rig, the effectiveness of the drill bits, and the experience of the drilling crew all play a role. Non-productive time (NPT) due to equipment breakdowns, unexpected geological challenges, or waiting on materials can significantly prolong the drilling schedule.

- Well Completion and Stimulation: After drilling, the well needs to be completed, which involves installing casing, cementing, and perforating. For unconventional wells, hydraulic fracturing (fracking) is a multi-stage process that can add days to weeks to the overall timeline, depending on the number of stages.

- Regulatory and Permitting Processes: The time required to obtain all necessary permits and adhere to environmental regulations can vary greatly by region and project, sometimes adding significant delays before drilling can even commence.

How to Drill a Natural Gas Well?

Drilling a natural gas well is a sophisticated multi-stage process, involving meticulous planning, specialized equipment, and highly skilled personnel to safely extract gas from underground reservoirs. Each step is critical to the well’s success.

Step 1: Site Preparation and Permitting

Before any drilling begins, extensive site preparation is required. This involves clearing land, leveling the area for the drilling pad, and constructing access roads. Concurrently, numerous permits must be secured from local, state, and federal authorities, ensuring environmental compliance and adherence to safety regulations.

Step 2: Rigging Up

Once the site is ready, the drilling rig is transported to the location and assembled. This process, known as “rigging up,” involves setting up the derrick, power systems, mud pumps, and other essential components. Safety checks are rigorously performed before operations commence.

Step 3: Spudding In and Surface Casing

“Spudding in” is the term for starting to drill the initial, wide-diameter hole. This shallow section is then lined with steel pipe called surface casing, which is cemented into place. This casing protects groundwater and provides stability for subsequent drilling operations.

Step 4: Drilling Deeper Sections

After the surface casing is set, drilling continues with progressively smaller drill bits to reach deeper geological formations. Intermediate and production casing strings are run and cemented at various depths to support the wellbore and isolate different rock layers and fluids.

Step 5: Well Logging and Evaluation

As drilling progresses, various logging tools are lowered into the wellbore to gather data. These tools measure properties like rock porosity, permeability, and fluid content, helping geologists identify potential gas-bearing formations and assess their commercial viability.

Step 6: Casing and Cementing the Production String

Once the target gas reservoir is reached, the final production casing is run down to the total depth. Cement is then pumped down and around the casing to permanently bond it to the rock, creating a seal that prevents gas migration and protects the well.

Step 7: Well Completion

Well completion prepares the well for gas production. This often involves perforating the casing within the gas-bearing zone, creating pathways for gas to flow into the wellbore. Production tubing is then installed, and the wellhead equipment is set up at the surface.

Step 8: Hydraulic Fracturing (for Unconventional Wells)

For many unconventional gas wells (e.g., shale gas), hydraulic fracturing, or “fracking,” is performed. This involves pumping high-pressure fluid, sand, and chemicals into the well to create and hold open tiny fissures in the rock, enhancing gas flow.

Step 9: Production and Well Abandonment

After completion, the well begins producing natural gas. Once the well’s economic life ends, it undergoes a meticulous abandonment process. This involves plugging the well with cement, removing surface equipment, and restoring the site to its original condition.

Oil and Gas Well Drilling Terminology

The oil and gas well drilling industry employs a specialized vocabulary to describe its complex processes, equipment, and geological conditions. Understanding these terms is essential for anyone involved in or learning about this critical sector of the energy industry, as they facilitate clear communication and technical understanding from the rig floor to the boardroom.

- Wellbore: The actual hole drilled into the earth, which can be vertical, horizontal, or deviated.

- Drill String: The assembly of drill pipe, drill collars, and the drill bit that extends from the rig’s surface equipment down into the wellbore.

- Drilling Mud (or Drilling Fluid): A specially formulated fluid circulated down the drill string and back up the annulus to cool the bit, carry cuttings to the surface, and control subsurface pressures.

- Casing: Steel pipes installed and cemented into the wellbore to prevent the hole from collapsing, isolate different formations, and protect groundwater.

- Blowout Preventer (BOP): A critical safety device installed at the wellhead that can seal off the wellbore to prevent uncontrolled flow of oil, gas, or other fluids to the surface (a “blowout”).

- Formation: A distinct layer of rock or geological material underground, often containing hydrocarbons.

- Rate of Penetration (ROP): The speed at which the drill bit cuts through rock, typically measured in feet per hour or meters per hour.

- Total Depth (TD): The final depth of the well, or the maximum depth drilled.

- Completion: The process of preparing a well for production after drilling, which includes perforating the casing and installing production tubing and wellhead equipment.

- Hydraulic Fracturing (Fracking): A stimulation technique where high-pressure fluid is pumped into the well to create fractures in the rock, allowing hydrocarbons to flow more freely.

How Much Does It Cost to Drill a Gas Well?

The cost to drill a natural gas well can vary dramatically, ranging from hundreds of thousands to tens of millions of US dollars, largely depending on the well’s complexity, depth, location, and the prevailing market conditions. Unconventional horizontal wells, particularly those requiring hydraulic fracturing (fracking), are significantly more expensive than shallower, conventional vertical wells due to the extensive infrastructure, specialized equipment, and personnel required.

This substantial investment encompasses every stage of the project, from initial geological surveys to site restoration, and is influenced by a multitude of factors, making each well a unique financial undertaking.

Here are the key factors influencing the cost of drilling a gas well:

- Depth and Complexity: Deeper wells and those with complex trajectories (e.g., horizontal or highly deviated wells) require more drilling time, specialized equipment, and greater volumes of materials like casing and drilling fluids, significantly increasing costs.

- Geological Formations: Drilling through hard, abrasive, or unstable rock formations, or encountering high-pressure zones, can slow down drilling, wear out drill bits faster, and necessitate more complex drilling techniques and safety measures, driving up expenses.

- Location and Accessibility: Wells in remote, challenging terrains (like mountains or swamps), or offshore environments, incur higher costs due to increased logistics for transporting equipment, personnel, and supplies, as well as the need for specialized offshore rigs.

- Regulatory and Environmental Compliance: Obtaining permits, conducting environmental impact assessments, and adhering to strict safety and environmental regulations can add substantial costs, especially in heavily regulated regions or sensitive ecosystems.

- Well Completion and Stimulation: After drilling, the well needs to be “completed” to allow gas flow. This often involves casing, cementing, and perforation. For unconventional wells, hydraulic fracturing (fracking) is a major cost component, involving large volumes of water, proppants (like sand), and specialized pumping equipment.

- Rig Rates and Service Costs: The daily rental rates for drilling rigs, the cost of specialized services (e.g., logging, cementing, mud engineering), and labor costs for skilled personnel all contribute significantly to the total expenditure and fluctuate with market demand.

| Cost Category | Typical Range (USD) | Notes |

| Leasing & Land Acquisition | $100,000 – $1,000,000+ | Varies widely based on land value, mineral rights, and negotiation complexity. |

| Site Preparation & Infrastructure | $100,000 – $400,000+ | Includes road construction, drilling pad preparation, and establishing necessary facilities. |

| Rig Mobilization & Demobilization | $100,000 – $350,000+ | Cost to transport the drilling rig to the site and set it up, then remove it afterwards. |

| Drilling Operations | $1,000,000 – $10,000,000+ (for horizontal wells) | Includes daily rig rates, drill bits, drilling fluids (mud), casing, cementing, and labor for the actual drilling process. This is often the largest single component. |

| Well Completion & Stimulation (Fracking) | $1,000,000 – $3,000,000+ (for horizontal wells) | Involves inserting production tubing, perforating the casing, and for unconventional wells, hydraulic fracturing with large volumes of fluid and proppant. This can be one of the highest costs for modern shale gas wells. |

| Surface Equipment | $75,000 – $750,000+ | Wellhead, production facilities, separation equipment, and flowlines to connect the well to pipelines. |

| Permitting & Regulatory Compliance | $10,000 – $100,000+ | Costs associated with obtaining necessary permits, environmental impact studies, and adherence to safety and environmental regulations. Can be significantly higher in complex regulatory environments. |

| Total Average Cost (Typical Horizontal Unconventional Well) | $6,000,000 – $8,000,000+ | This is a broad average; complex offshore wells or ultra-deep wells can exceed $100,000,000, while very shallow, conventional wells might be under $1,000,000. Costs are also sensitive to oil and gas prices, which affect market demand for drilling services and materials. |

How to Choose Suitable Drill Bits for Gas Well Drilling

Choosing the suitable drill bit for gas well drilling is a crucial decision that significantly impacts drilling efficiency, cost, and overall project success. This selection process is a careful balance of understanding downhole conditions, desired outcomes, and available technology. It’s not a one-size-fits-all approach, as different geological formations and drilling objectives necessitate specific bit characteristics.

Here are the key factors to consider when selecting the suitable drill bits for gas well drilling:

- Formation Characteristics: This is arguably the most critical factor. Drill bits must be matched to the rock’s hardness, abrasiveness, and stickiness. Soft formations might require bits with long, widely spaced teeth (like certain milled tooth roller cones or aggressive PDC bits), while hard, abrasive formations demand bits with robust tungsten carbide inserts or diamond cutters (like TCI roller cones or durable PDC/natural diamond bits).

- Drilling Objectives & Well Profile: The desired rate of penetration (ROP), the need for directional control, and the overall well trajectory (vertical, horizontal, or complex deviated wells) heavily influence bit choice. For instance, PDC bits are often favored for their superior ROP in directional drilling, while certain roller cones might be chosen for maintaining a straight bore in specific hard rock layers.

- Drilling Parameters & Equipment: The capabilities of the drilling rig, including available weight on bit (WOB), rotary speed (RPM), and pump capacity for drilling fluid circulation, must align with the bit’s requirements. An aggressive bit may require higher WOB and RPM, while a less robust rig might necessitate a more forgiving bit design.

- Hydraulics & Hole Cleaning: Effective removal of cuttings from the bottom of the hole is vital for bit performance and preventing “balling” (cuttings sticking to the bit). The bit’s nozzle design and the properties of the drilling fluid must ensure optimal hydraulic energy at the bit face to clean it efficiently.

- Cost-Effectiveness & Bit Life: While initial bit cost is a factor, the overall cost per foot drilled is more important. A more expensive bit that drills faster and lasts longer, reducing trip time for bit changes, can be more economical in the long run. The balance between ROP and bit durability is constantly evaluated.

- Offset Well Data: Analyzing data from previously drilled wells in similar geological areas provides invaluable insights into which bits performed best under comparable conditions. This historical data often guides initial bit selection and can highlight potential challenges to anticipate.

Conclusion

The continuous innovation in drill bit technology is undeniably a cornerstone of modern gas well drilling. As we’ve explored, optimizing these critical tools is not just about speed, but about achieving greater precision, extending bit life, and ultimately enhancing the economic viability of extracting this essential energy resource from increasingly challenging geological formations.

The future of gas well drilling will undoubtedly see even more sophisticated drill bit designs, incorporating artificial intelligence, advanced materials, and real-time data analysis to push the boundaries of what’s possible. These advancements promise to further reduce environmental impact and improve the safety and efficiency of drilling operations worldwide.

For those looking to leverage these advancements and optimize their drilling operations, high-quality drill bits are essential. Consider sourcing your wholesale drill bits for gas well drilling from Sinodrills, a trusted partner committed to providing cutting-edge solutions that will help you achieve success from rock to resource.