Custom Hole Opener Drill Bit Manufacturer in China

As a leading custom hole opener drill bit manufacturer in China, we specialize in designing and producing bespoke drilling solutions. Our expertise lies in creating high-performance tools tailored to specific geological conditions and project requirements. Utilizing advanced technology and premium materials, we deliver durable, efficient, and reliable hole openers for challenging drilling operations worldwide.

Sinodrills - Your Trusted Hole Opener Drill Bit Manufacturer from China

Sinodrills is your trusted hole opener drill bit manufacturer from China, specializing in custom solutions. We deliver high-performance tools engineered with premium materials for durability and efficiency in diverse geological conditions. Our commitment to quality, backed by years of expertise, ensures reliable results and the lowest drilling cost per meter for your projects worldwide.

Your Leading Hole Opener Drill Bit Manufacturer from China

Sinodrills provides a comprehensive range of hole opener drill bits, specializing in creating high-performance, custom drilling tools. Our commitment to excellence ensures we deliver durable and efficient solutions for various drilling applications.

Custom-Engineered Solutions: We design and manufacture bespoke hole openers tailored to specific geological conditions and project needs.

Superior Quality & Durability: Made with premium materials and advanced manufacturing techniques, our tools offer exceptional longevity and reliability.

Global Expertise: With years of experience serving clients worldwide, we understand the diverse challenges of drilling and provide expert advice to optimize your operations.

Hole Opener Drill Bit Functions

Borehole Enlargement: The main function is to increase the diameter of a pre-drilled pilot hole. This is essential for accommodating larger casing, production equipment, or simply to meet project specifications.

Wellbore Stabilization: By enlarging the borehole, the hole opener creates a smoother and more uniform wellbore wall. This reduces the risk of wellbore instability, such as collapse or swelling, which can hinder subsequent operations.

Improved Casing Installation: A smoother, larger borehole allows for easier and more efficient installation of casing, minimizing the risk of the casing getting stuck.

Reaming and Cleaning: Hole openers are used to clean out the borehole, removing accumulated cuttings, debris, and mud cake. This is particularly important in directional or horizontal drilling to ensure a clear path for the drill string.

Enhanced Drilling Performance: By providing more clearance for the drill string, the enlarged borehole can reduce torque and drag, allowing for better weight transfer to the bit and potentially increasing the rate of penetration.

Various Hole Opener Drill Bit

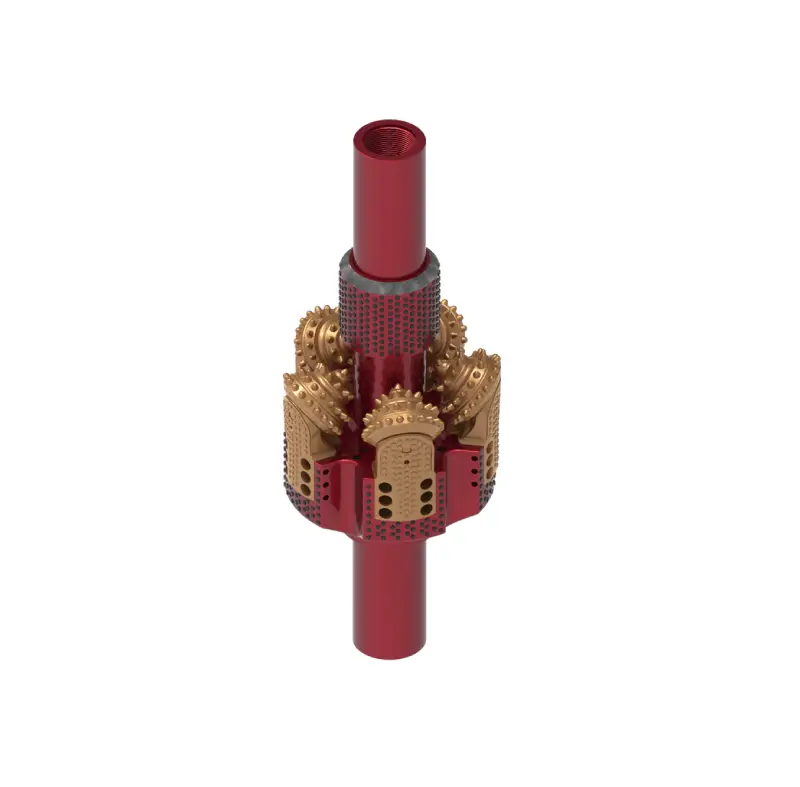

Hole Opener PDC drill bit

We offer high-performance Hole Opener PDC Drill Bits designed for efficient and fast drilling in medium to hard formations. Our bits feature superior Polycrystalline Diamond Compact cutters for enhanced durability and rate of penetration. With a robust design, they minimize vibration and ensure a stable and clean borehole, optimizing your drilling operations and reducing costs.

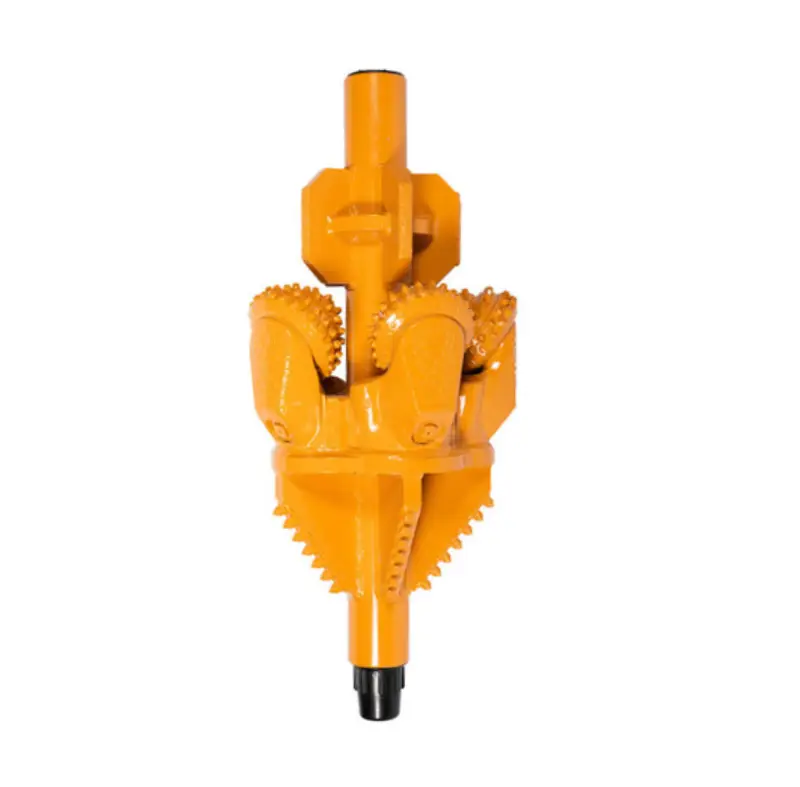

concentric/symmetric casing overburden drilling system with ring bit

We offer high-performance hole openers for rock drilling. Our robust tools feature durable cutters and optimized designs to enlarge boreholes in hard and abrasive formations efficiently. Whether for mining, water well, or foundation projects, our rock-drilling hole openers ensure superior stability, extended tool life, and a lower cost per meter.

DTH hole opener drill bits

We offer high-performance DTH hole opener drill bits, engineered for efficiency and durability in a variety of drilling applications. Our custom solutions are designed to enlarge pilot holes to your precise specifications, ensuring optimal performance in diverse rock formations. Our tools are made with premium materials for a long lifespan.

HDD hole opener drill bits

We offer a wide selection of HDD hole opener drill bits for horizontal directional drilling. Our range includes durable TCI and PDC cutters designed for different rock formations, from soft soil to hard rock. We provide both standard and custom-engineered solutions to meet your specific project requirements, ensuring efficiency and reliability in every bore.

hole opener reamer bit

We offer high-performance hole opener reamer bits designed for enlarging existing boreholes. Our reamers are engineered with robust cutters and durable bodies to ensure efficient and stable reaming in diverse rock formations. We provide customized solutions to match your specific drilling requirements, helping you achieve optimal performance and extended tool life.

roller cone hole opener drill bit

We offer roller cone hole opener drill bits for various drilling applications. Our bits feature robust designs with either milled steel teeth for softer formations or tungsten carbide inserts for harder rock, ensuring durability and efficiency. With a focus on superior engineering and quality materials, we provide reliable tools that optimize your drilling performance and reduce costs.

offshore hole opener drill bit

We offer a wide range of offshore hole opener drill bits, engineered for the demanding conditions of marine drilling. Our specialized tools are designed to enlarge boreholes in challenging subsea environments with exceptional efficiency and reliability. Utilizing corrosion-resistant materials and robust designs, our bits ensure superior performance and longevity, minimizing downtime and reducing operational costs for your offshore projects.

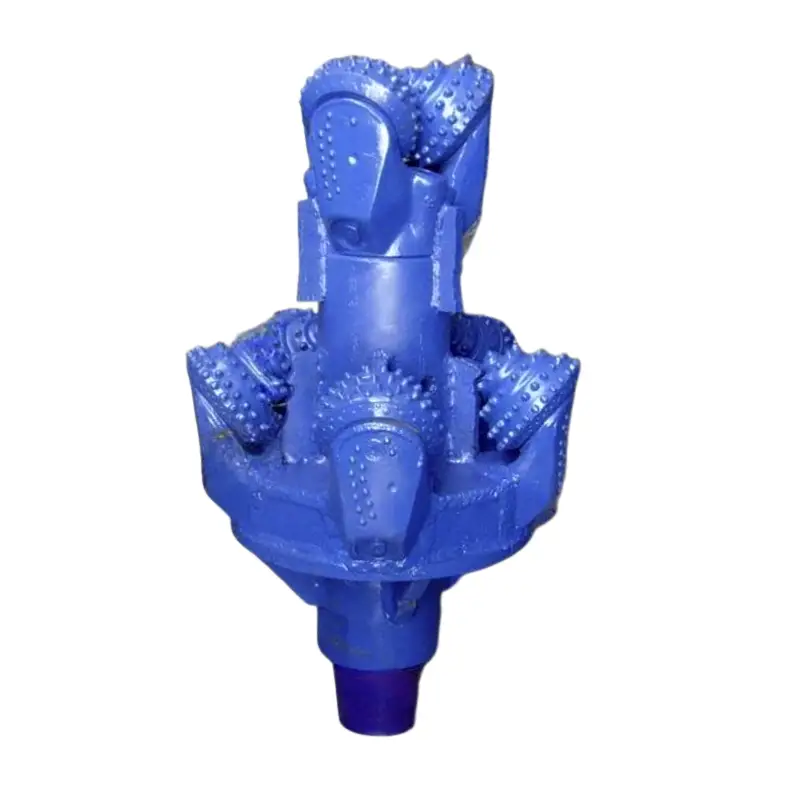

roller cone embedded hole opener

We offer a wide range of offshore hole opener drill bits, engineered for the demanding conditions of marine drilling. Our specialized tools are designed to enlarge boreholes in challenging subsea environments with exceptional efficiency and reliability. Utilizing corrosion-resistant materials and robust designs, our bits ensure superior performance and longevity, minimizing downtime and reducing operational costs for your offshore projects.

rock reamer hole opener

We offer heavy-duty rock reamer hole openers designed for Horizontal Directional Drilling (HDD) projects. These tools aggressively enlarge pilot holes in hard rock and mixed ground using TCI (Tungsten Carbide Insert) cutters. Our customizable, field-replaceable designs ensure maximum durability, low torque, and superior efficiency, minimizing trip time and overall drilling costs for large-diameter bores.

Customize Your Desired Hole Opener Drill Bit

Cutting Structure & Formation Type

We design the cutting structure to match the geological formation you’re drilling. Whether it’s soft, medium, or hard rock, we select the ideal cutters—from steel tooth to TCI (tungsten carbide inserts) or roller cones—to ensure maximum efficiency and penetration, minimizing wear and tear.

Bit Body & Diameter

The bit body is engineered to withstand extreme downhole conditions. We customize the body’s design and diameter to meet your specific project requirements, ensuring a precise and stable cut. This includes adjusting the number of cutters and overall tool length for optimal performance.

Connection Type & Size

To ensure seamless integration with your existing drill string, we customize the connection type and size. We can manufacture the tool with various API and proprietary connections, ensuring it fits perfectly with your equipment. This reduces rig time and prevents compatibility issues.

Additional Features & Functionality

We can add specialized features to enhance performance. This includes designing for specific flow rates and nozzle configurations for improved cuttings removal, or integrating stabilizers to maintain directional control and reduce vibration. We tailor these elements to optimize your drilling operation.

What is a hole opener drill bit?

A hole opener drill bit is a specialized tool used in drilling operations to enlarge a pre-drilled pilot hole to a larger, specified diameter.

Unlike a conventional drill bit that starts a new hole, its primary purpose is to ream an existing one. This process is essential in various industries, including oil and gas, horizontal directional drilling (HDD), and mining.

Key components of a hole opener typically include:

Pilot Bit/Reamer: A smaller bit at the front of the tool that guides it by following the path of the initial pilot hole.

Cutters: These are positioned around the tool’s body and are responsible for enlarging the hole. They can be either fixed blades (used for softer formations) or rotating roller cones (for harder rock formations).

Body: The central structural component that holds the cutters and connects the tool to the drill string.

The function of a hole opener is to ensure that a borehole is wide enough to accommodate larger casing, pipelines, or other downhole equipment. By providing a clean, stable, and correctly sized borehole, it helps prevent issues like borehole collapse and allows for more efficient and successful completion of a drilling project.

What is hole opener drill bit used for?

A hole opener drill bit is primarily used to enlarge a pre-drilled pilot hole to a larger, specified diameter. This process is crucial in various drilling operations where a single-pass drilling system is not feasible or efficient.

By following a smaller pilot hole, the hole opener ensures the final borehole is straight, stable, and precisely sized for the next phase of the project. Its applications are vital across multiple industries, including:

Oil and Gas: To prepare wellbores for the installation of larger-diameter casing, which is essential for well integrity and production.

Horizontal Directional Drilling (HDD): Used to ream and enlarge boreholes for the installation of large pipes for utilities like water, sewer, and gas lines, or fiber optic cables.

Mining and Quarrying: To create large-diameter holes for ventilation shafts, access points, or for blasting purposes.

Civil Construction: For creating foundations, pilings, and other large-diameter holes in various ground conditions.

How do you maintain a hole opener drill bit?

Proper maintenance is crucial for extending the life of a hole opener and ensuring safe operation. Key maintenance practices include:

Regular Inspection: Before and after each run, check for cracks, worn cutters, and loose connections.

Lubrication: If the tool has roller cone cutters, ensure the bearings are properly lubricated according to the manufacturer’s guidelines.

Proper Handling: Avoid dropping or mishandling the tool, which can damage the cutters and body.

Cleaning: Thoroughly clean the tool after each use to remove drilling fluid and cuttings, preventing corrosion and buildup.

Can hole openers be customized for specific projects?

Yes, customization is one of the most significant advantages of using hole openers. Manufacturers can design and build tools to meet specific project requirements. Customization can include:

Diameter: The exact size of the enlarged hole.

Number and Type of Cutters: Tailored for the specific rock formation.

Connection Type: To ensure compatibility with the rig’s drill string.

Fluid Nozzles: To optimize mud flow for better cuttings removal.

why choose our hole opener drill bits?

Choosing our hole opener drill bits means choosing a partner committed to your project’s success. We stand out for our unwavering focus on performance, quality, and customer-centric solutions.

Here’s why you should choose us:

-

Customization to Your Needs: We don’t offer a one-size-fits-all solution. Our team designs and manufactures bespoke hole openers tailored to your specific geological formations, rig capabilities, and project requirements, ensuring optimal performance and efficiency.

-

Superior Quality and Durability: We use only the highest-grade materials and advanced manufacturing techniques. Our bits are engineered to withstand the most demanding conditions, providing exceptional longevity, reducing downtime, and lowering your drilling cost per meter.

-

Expert Support and Service: With decades of experience in the drilling industry, our experts provide comprehensive technical support, from initial consultation and design to after-sales service. We are committed to helping you find the perfect solution and troubleshooting any challenges.

-

Competitive Pricing: As a leading manufacturer from China, we offer a unique blend of high-quality products at competitive prices, giving you an excellent return on investment without compromising on performance or reliability.

Send Your Inquiry Now

All-in-one Hole Opener Drill Bit Solutions for Your Project

We provide all-in-one hole opener solutions, from initial consultation and custom design to manufacturing and after-sales support. We tailor each tool with the ideal cutting structure and body configuration for your specific geological conditions, ensuring maximum durability and efficiency. Our goal is to deliver a complete, high-performance drilling tool that maximizes your project’s success.