Choosing the right drill bit is crucial for efficient and cost-effective drilling operations. Two of the most common and widely utilized types of drill bits in the industry are PDC (Polycrystalline Diamond Compact) bits and tricone bits. While both are designed to penetrate rock, they employ fundamentally different mechanisms to achieve this, leading to distinct performance characteristics and ideal applications.

Understanding these differences is key to optimizing drilling projects, ensuring that the chosen bit is best suited for the specific geological conditions and operational goals. This blog will explore the core distinctions between PDC and tricone drill bits, comparing their design, working principles, advantages, disadvantages, and ideal applications to help you make an informed decision for your drilling needs.

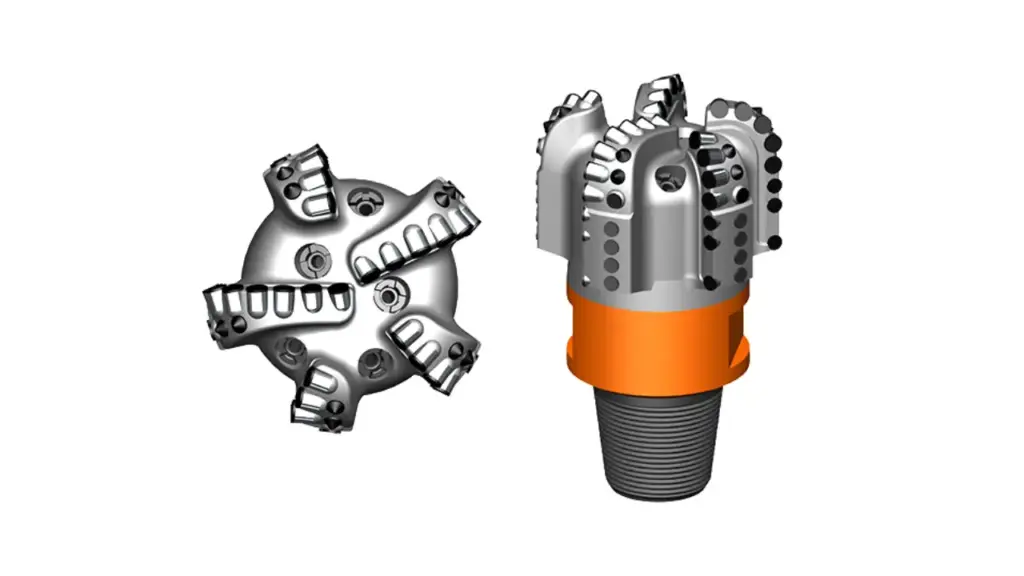

What is a PDC Drill Bit?

A PDC (Polycrystalline Diamond Compact) drill bit is a type of fixed-cutter drill bit widely used in various drilling applications, particularly in the oil and gas, mining, and geothermal industries. It is characterized by its cutting elements, known as PDC cutters, which consist of a layer of industrial-grade synthetic diamond bonded to a tungsten carbide substrate. This innovative design allows the bit to cut rock formations by a shearing and scraping action rather than a crushing motion.

This unique cutting mechanism provides several advantages, including significantly higher rates of penetration (ROP) and a longer lifespan compared to traditional roller cone bits, especially in softer to medium-hard and even some harder, abrasive formations. PDC bits are an integral part of modern drilling operations, designed for efficiency, durability, and reduced operational costs by minimizing the need for frequent bit changes.

What is a Tricone Drill Bit?

A tricone drill bit is a type of rotary drill bit characterized by its three conical rollers, each equipped with teeth or inserts, that rotate independently as the entire bit rotates. Invented by Howard Hughes Sr. in the early 20th century, these bits revolutionized drilling by providing a more effective method for penetrating hard rock formations than previous designs. As the drill string rotates, the cones on the tricone bit roll along the bottom of the borehole, and the teeth crush, chip, and abrade the rock, breaking it into smaller fragments.

Tricone bits are highly versatile and are classified based on their tooth material (steel tooth or tungsten carbide inserts – TCI), bearing type, and suitability for various rock formations (soft, medium, or hard). Steel tooth bits, or milled tooth bits, are typically used for softer formations, featuring longer and widely spaced teeth.

TCI bits, on the other hand, incorporate harder, more durable tungsten carbide inserts and are designed for medium to extremely hard and abrasive rock formations, offering extended bit life and enhanced performance.

PDC Drill Bit vs Tricone

When it comes to drilling through rock, selecting the right drill bit is paramount for efficiency, cost-effectiveness, and project success. Two of the most common and widely used types of drill bits are Polycrystalline Diamond Compact (PDC) bits and Tricone bits.

While both are designed to penetrate rock, they employ fundamentally different mechanisms and are best suited for distinct geological conditions. Understanding these differences is key to optimizing any drilling operation.

This comparison will delve into some critical aspects: their cutting mechanism, formation suitability, durability and lifespan, rate of penetration (ROP), and overall cost and maintenance considerations. By examining these factors, drillers can make informed decisions to maximize performance and minimize downtime in their specific applications.

Cutting Mechanism

PDC drill bits operate primarily through a shearing or scraping action. Their fixed cutters, made of synthetic diamond, are designed to continuously shave off layers of rock as the bit rotates. This continuous cutting motion generates less friction and heat compared to other bit types, allowing for smoother drilling and a more consistent borehole. The fixed nature of the cutters means there are no moving parts to wear out or seize, contributing to their extended lifespan in appropriate formations.

In contrast, tricone drill bits break rock through a combination of crushing, chipping, and grinding. Comprising three independently rotating cones, these bits utilize teeth or inserts (either milled steel or tungsten carbide) that impact and pulverize the rock as the cones roll along the bottom of the borehole. This dynamic action effectively fractures and dislodges rock fragments, making tricone bits particularly effective in formations that respond well to compressive forces.

Formation Suitability

PDC drill bits are generally most effective in soft to medium-hard, homogeneous formations, such as shales, limestones, and sandstones, that can be efficiently sheared. Their design allows for high rates of penetration in these consistent rock types, as the PDC drill bit cutters can maintain continuous contact and efficiently remove cuttings. However, they can be less effective and prone to damage in highly abrasive, fractured, or interbedded formations, where impact forces might chip or break the diamond cutters.

Tricone drill bits, due to their crushing and chipping action, are highly versatile and excel in a broader range of formations, including hard, fractured, or interbedded rock. They are particularly well-suited for formations with varying hardness layers or those containing chert, granite, or basalt, where the impact forces help break up the rock effectively. While they can also drill softer formations, their efficiency might be lower than PDC bits in those specific conditions.

Durability and Lifespan

PDC drill bits are known for their exceptional durability and long lifespan in ideal drilling conditions. The synthetic diamond cutters are extremely hard and wear-resistant, allowing them to maintain their sharpness over extended periods. The absence of moving parts like bearings further contributes to their longevity, reducing the risk of mechanical failure downhole. However, impact damage in very hard or fractured formations can lead to premature cutter wear or breakage.

Tricone drill bits, while robust, have moving parts, including bearings in each cone. The bearing type is a component crucial to the tricone bit’s performance and durability and can be a common point of failure. These moving parts are subject to wear and tear, especially in abrasive environments or at high rotational speeds, which can limit their overall lifespan. Regular lubrication and maintenance are essential for tricone bits to avoid premature failure.

Rate of Penetration (ROP)

PDC drill bits generally offer a significantly higher Rate of Penetration (ROP) in formations where they are well-suited. Their continuous shearing action allows for faster cutting and more efficient removal of rock chips, which translates to quicker drilling times. This high ROP is a major advantage in projects where maximizing drilling speed and minimizing rig time are critical, such as in long horizontal wells.

Tricone drill bits, while robust, typically have a lower ROP compared to PDC bits in soft to medium formations. Their crushing and chipping action, while effective for hard rock, is inherently less efficient for continuous, rapid penetration. However, in extremely hard or fractured formations where PDC bits might struggle or become damaged, tricone bits can maintain a more consistent, albeit slower, ROP without experiencing excessive wear or failure.

Cost and Maintenance

The initial cost of PDC drill bits is generally higher than that of tricone bits, primarily due to the complex manufacturing process and the use of synthetic diamond materials. However, their extended lifespan and higher ROP can often lead to lower overall drilling costs by reducing the number of bit changes required, minimizing tripping time, and increasing overall drilling efficiency. PDC bits require less maintenance downhole due to the absence of moving parts.

Tricone drill bits typically have a lower upfront cost, making them an attractive option for projects with tighter budgets or less demanding drilling conditions. However, their moving parts (bearings) require lubrication and are prone to wear, which can lead to higher maintenance requirements and potential failure during drilling operations. If a part of the tricone bit is lost in the borehole, it can result in costly fishing operations to retrieve the lost components.

Here is the table showing you the differences between PDC drill bits and Tricone drill bits as follows:

| Feature | PDC Drill Bit | Tricone Drill Bit |

|---|---|---|

| Cutting Mechanism | Shearing and scraping rock | Crushing, chipping, and grinding rock |

| Primary Motion | Fixed cutters shear rock continuously | Rotating cones with teeth/inserts impact rock |

| Moving Parts | None (fixed cutters) | Three independently rotating cones with bearings |

| Formation Suitability | Soft to medium-hard, homogeneous, non-abrasive rocks (e.g., shale, limestone, sandstone) | Wide range: soft, medium, hard, fractured, abrasive, or interbedded rocks (e.g., granite, basalt, chert) |

| Durability & Lifespan | Excellent in suitable formations; diamond cutters highly wear-resistant; no mechanical failure points. | Good; lifespan limited by bearing and seal wear; more prone to mechanical failure from moving parts. |

| Rate of Penetration (ROP) | Generally higher in suitable formations (faster drilling). | Generally lower than PDC in soft/medium formations; consistent in hard/fractured formations. |

| Initial Cost | Higher | Lower |

| Long-term Cost | Often lower due to fewer bit changes and higher ROP. | Can be higher due to more frequent replacements and maintenance. |

| Maintenance | Low (no moving parts to lubricate or wear out). | Higher (requires lubrication, susceptible to bearing failure). |

How to Choose PDC Drill Bit and Tricone Drill Bit?

Choosing between a PDC drill bit and a tricone drill bit is a critical decision that significantly impacts drilling efficiency, cost, and overall project success. The optimal selection depends on a thorough analysis of geological conditions, desired performance, and economic considerations. Here are key factors to consider:

- Formation Type and Hardness: Evaluate the rock’s characteristics, including its hardness, abrasiveness, and homogeneity. PDC bits excel in soft to medium-hard, consistent formations that can be sheared (e.g., shale, sandstone), while tricone bits are highly versatile and preferred for harder, more fractured, or interbedded formations that require crushing (e.g., granite, chert).

- Desired Rate of Penetration (ROP): If maximizing drilling speed is the top priority in suitable formations, a PDC bit is often the better choice due to its continuous cutting action and higher ROP. For hard, challenging formations where speed might be secondary to consistent performance and bit survival, a tricone bit can provide a reliable, albeit slower, drilling rate.

- Drilling Environment and Conditions: Consider factors like temperature, pressure, and the presence of abrasive materials or junk in the hole. PDC bits are generally more sensitive to impact damage from hard stringers or junk, whereas tricone bits, with their robust rolling action, can often handle such conditions more effectively, though their bearings can be susceptible to wear in abrasive environments.

- Cost and Lifespan (Total Cost of Ownership): While PDC bits typically have a higher initial purchase price, their longer lifespan and faster drilling can lead to lower overall costs per foot by reducing trips and downtime. Tricone bits have a lower upfront cost but may require more frequent replacement and maintenance due to moving parts, potentially increasing long-term expenses.

- Directional Control Requirements: PDC bits often offer better steerability and smoother torque, which can be advantageous for directional drilling applications where precise wellbore trajectories are needed. Tricone bits, while capable of directional drilling, might offer less precise control in comparison, depending on the specific bit design and formation.

Conclusion

PDC and tricone drill bits each offer distinct advantages, making the choice dependent on specific geological conditions and project goals. PDC bits excel in shearing softer to medium-hard abrasive formations with superior ROP, while tricone bits dominate in crushing harder, more fractured, or interbedded rock types.

Understanding these fundamental differences is crucial for optimizing drilling efficiency and extending tool life. Selecting the appropriate bit minimizes operational costs and enhances overall project productivity. Both technologies continue to evolve, offering increasingly specialized solutions for diverse drilling challenges.

For all your drilling needs, including wholesale PDC and tricone drill bits, consider Sinodrills. We offer a comprehensive range of high-quality drill bits engineered for optimal performance across various rock formations and drilling applications, ensuring your projects are equipped for success.