Custom Step Drag Bit Manufacturer in China

As a leading supplier, Sinodrills offers step drag bits engineered for efficient drilling in softer geological formations. Our step drag bits, typically featuring three wings with tungsten carbide cutting tips, are designed for aggressive cutting and a high rate of penetration in materials like clay, loam, and silt. These cost-effective tools are ideal for water well drilling, mining exploration, and environmental applications at shallower depths.

Sinodrills - Your Trusted Step Drag Bit Manufacturer from China

Sinodrills, a reputable drill bit manufacturer based in China, provides reliable step drag bits for diverse drilling needs. Our expertly engineered bits, often featuring robust tungsten carbide inserts, ensure efficient and cost-effective penetration in unconsolidated formations like clay, sand, and soft rock. We offer various sizes and configurations, adhering to stringent quality standards, making us your trusted partner for water well, mining, and geotechnical drilling projects.

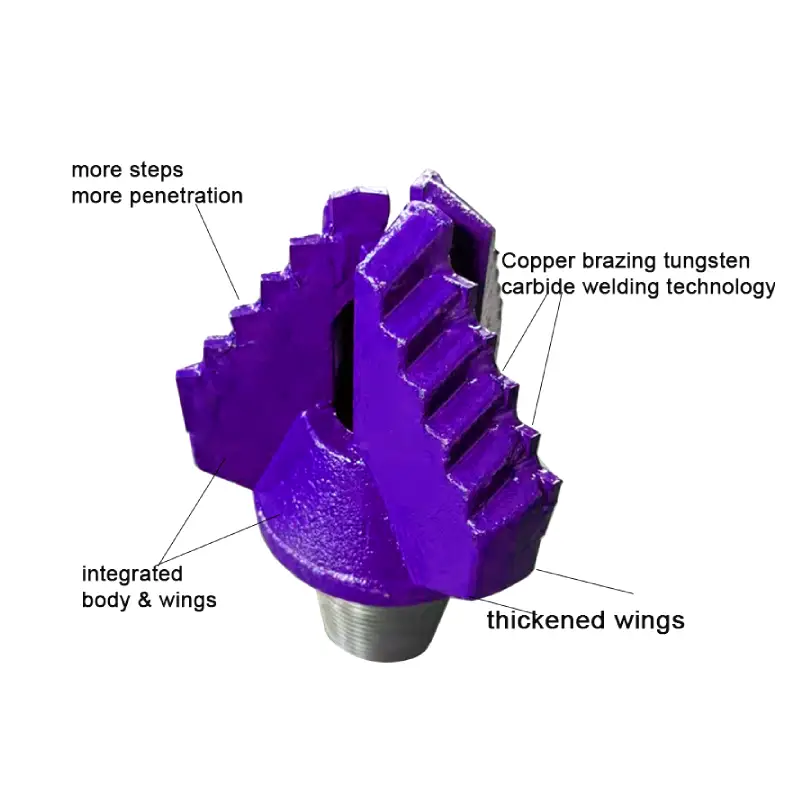

Why Step Drag Drill Bits

More Steps, More Penetration: The multi-step design optimizes cutting action, allowing each “step” to engage the rock independently. This segmented approach ensures consistent and aggressive removal of material, leading to a significantly higher rate of penetration (ROP) and faster drilling progress in various formations.

Integrated Body & Wings: Crafted as a single, cohesive unit, the integrated design eliminates weak points often found in multi-part bits. This robust construction delivers exceptional strength and stability, allowing the bit to endure severe torsional and impact stresses without failing, thus extending its operational lifespan.

Copper Brazing Tungsten Carbide Welding Technology: This advanced joining method creates an incredibly strong, high-temperature bond between the bit body and its tungsten carbide cutters. This superior adhesion prevents premature shedding of the durable cutting elements, ensuring sustained drilling performance and reliability even in challenging abrasive conditions.

Thickened Wings: Designed with increased material thickness, the wings offer superior rigidity and resistance to wear. This reinforcement minimizes bit deflection and vibration, leading to a smoother drilling operation and better hole quality. The robust wings also provide excellent protection against gauge loss.

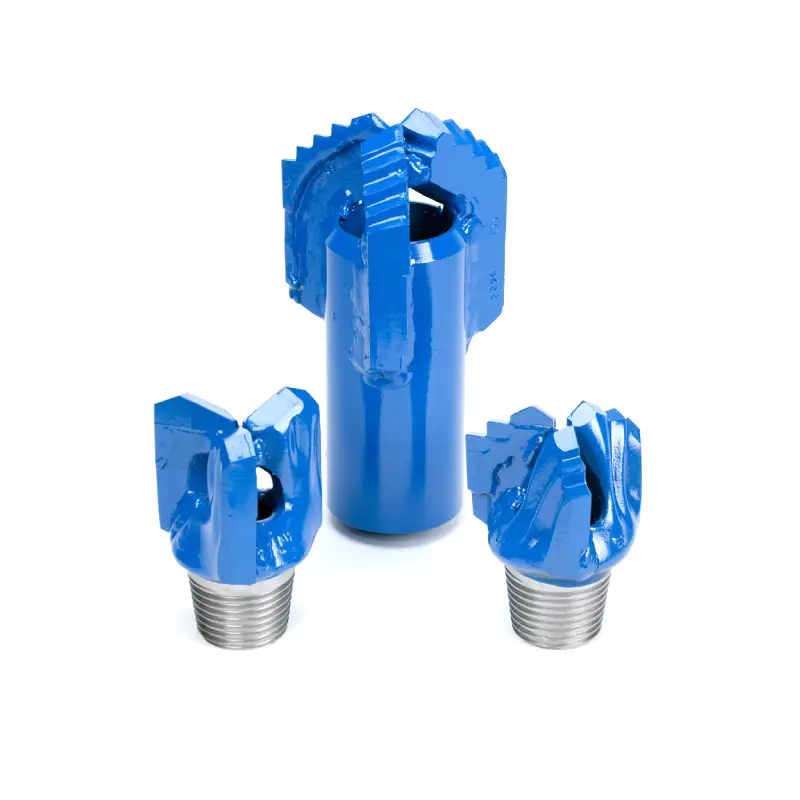

Various Step Drag Bit

step drag drill bits

Step drill bits are versatile tools for drilling multiple hole sizes in metal, plastic, and wood. We offer durable, precision-made step drill bits suitable for professional use. Designed for smooth cutting, long life, and easy operation, our selection ensures efficiency and accuracy for every project.

3 wing step drill bit

Sinodrills offers durable and efficient 3-wing step drill bits, expertly designed for rapid penetration in softer geological formations. Featuring robust tungsten carbide cutting edges, these bits deliver cost-effective performance in materials like clay, sand, and shale. Ideal for water well drilling, geotechnical investigations, and shallow oil and gas exploration, our 3-wing step drill bits are manufactured to high standards for reliable and consistent results. Choose Sinodrills for your drilling needs.

alloy step drag bit for drilling

Sinodrills offers robust alloy step drag bits designed for efficient drilling in various formations. Constructed with high-quality alloy steel and often featuring durable tungsten carbide inserts, our bits ensure effective penetration and longevity in softer to medium-hard ground conditions. The stepped design facilitates aggressive cutting action and efficient cuttings removal, making them ideal for water well, mining exploration, and geotechnical applications. Choose Sinodrills for reliable and cost-effective drilling solutions.

rotary drilling three wing step drag bits

Sinodrills offers a wide range of rotary drilling three-wing step drag bits, engineered for efficient and cost-effective penetration in soft to medium-hard formations. Our bits feature durable tungsten carbide cutting edges, ensuring aggressive cutting action and high rates of penetration in applications like water well drilling, geotechnical investigations, and shallow oil and gas exploration. Available in various sizes and connections, our step drag bits provide reliable performance and extended service life.

carbide step drag bit

Sinodrills offers a wide selection of carbide step drag bits, engineered for optimal performance in soft to medium-hard formations. Our bits feature durable tungsten carbide inserts strategically placed for aggressive cutting action and efficient hole cleaning. Designed for water well drilling, mining exploration, and geotechnical investigations, our carbide step drag bits provide a cost-effective and reliable solution for achieving high penetration rates and extended service life in various subsurface conditions.

rock drilling step drag bits

Sinodrills provides durable and efficient rock drilling step drag bits, expertly designed for optimal performance in softer to medium-hard rock formations. Our bits, often featuring robust tungsten carbide cutting edges, ensure effective penetration and a high rate of advance. Ideal for water well drilling, mining exploration, and geotechnical investigations, our step drag bits offer a cost-effective and reliable solution for your rock drilling needs. Choose Sinodrills for quality and performance.

step drag drill bits for water well

We offer a wide selection of step drag drill bits, perfect for water well drilling in soft to medium formations like clay, sand, and weathered rock. Our bits, often featuring robust tungsten carbide cutting tips, ensure aggressive cutting and high penetration rates. We provide various sizes and configurations for efficient and cost-effective drilling.

Chevron drag bit for mining water well drilling

We offer Chevron drag bits, ideal for mining and water well drilling. Our bits feature robust alloy steel bodies with durable tungsten carbide inserts, ensuring extended life and efficient penetration in medium to hard formations like shale and limestone. Available in various sizes and wing configurations (3 or 4 wings), they provide stability and effectiveness for diverse drilling projects.

3 wing step drag drill bit

We offer 3-wing step drag drill bits, ideal for drilling in soft to medium formations like clay, sand, and shale. These bits feature durable alloy steel construction with tungsten carbide cutting tips, ensuring fast penetration and efficient spoil removal. Perfect for water well, mining, geothermal, and environmental drilling applications.

3 wing step API reg pin drag bit

We offer a high-performance 3-wing step API regular pin drag bit, engineered for efficient drilling in various formations. Its robust design ensures durability and stability, minimizing wear and tear. The precision-engineered cutting structure provides optimal penetration rates and superior hole quality. Ideal for soft to medium-hard ground, this bit reduces drilling time and costs, enhancing productivity for your operations.

PDC step drag drill bits

We offer well-designed PDC step drag drill bits, engineered for efficient drilling in soft to medium formations like sand, clay, shale, and limestone. Designed with robust PDC cutters, these bits deliver superior penetration rates and extended tool life. Ideal for water well, mining, geothermal, and mineral exploration, our step drag bits ensure productivity in various drilling applications.

multi-function step drag drill bits with 4 wings

Introducing our multi-function step drag drill bits with 4 wings, a versatile tool for efficient drilling. Each bit features a unique step design for varying hole sizes and four durable wings for enhanced stability and faster penetration. Our premium steel construction ensures long-lasting performance across diverse materials.

3 wing step drag drill bits for water well

We offer three-wing step drag drill bits for water well drilling. Our bits are designed for fast penetration and superior performance in soft to medium rock formations. They feature a unique stepped design and high-quality carbide inserts for maximum durability and efficiency.

wing type step drag bits

Step drag bits are an ideal choice for drilling in soft to medium rock formations. Their unique design features a stepped cutting profile, which reduces torque and enhances drilling efficiency. They are especially effective for drilling applications in oil, gas, mining, and water well industries. We offer a variety of sizes and configurations to meet your specific needs.

TCI step drag bits

We offer TCI step drag bits designed for efficient rock drilling and long-lasting performance. Engineered with durable tungsten carbide inserts, our step drag bits ensure precise cutting, enhanced wear resistance, and maximum drilling speed. Ideal for various mining and construction applications, we provide reliable solutions that improve productivity and reduce operational costs.

step drag bit with 3 blades

We offer high-performance Step Drag Bits with 3 blades, designed for efficient rock drilling and extended durability. Our bits ensure precise cutting, improved penetration, and reduced wear, making them ideal for various geological conditions. Engineered for reliability, these 3-blade step drag bits deliver consistent results, boosting productivity and minimizing downtime on every drilling project.

chevron step drag bits

We specialize in chevron step drag drill bits, engineered for superior performance in various ground conditions. Their unique chevron-patterned cutting steps enhance rock engagement and optimize debris removal, leading to faster penetration rates and extended bit life. These robust bits deliver exceptional drilling efficiency, making them ideal for demanding applications requiring consistent performance and durability.

alloy steel 4 blade step drag bit

We specialize in providing high-quality alloy steel 4-blade step drag bits, engineered for superior performance in various drilling applications. Our bits feature a robust design with precisely angled steps on each blade, maximizing penetration rates and drilling efficiency in soft to medium-hard formations. We offer a range of sizes to meet diverse project requirements.

3 wing PDC step drag drill bits

We offer 3 wing PDC step drag drill bits designed for efficient drilling in soft to medium-hard formations. These bits feature precision-engineered PDC cutters that enhance penetration rates and reduce wear. Ideal for mining and construction applications, our 3 wing PDC step drag drill bits deliver reliable performance, durability, and cost-effective drilling solutions.

4 wing PDC step drag drill bits

We offer 4 wing PDC step drag drill bits designed for efficient drilling in medium to hard rock formations. These bits feature four cutting wings with polycrystalline diamond compact (PDC) inserts, ensuring high penetration rates, enhanced durability, and long service life. Ideal for oil, gas, and mining applications.

5 wing PDC step drag drill bits

We offer 5 wing PDC step drag drill bits designed for efficient and precise drilling in various rock formations. These bits provide superior penetration rates, enhanced stability, and long-lasting durability. Ideal for both soft and medium-hard rocks, our 5 wing PDC step drag drill bits ensure consistent performance and reduced operational costs for every drilling project.

6 wing PDC step drag drill bits

We offer 6 wing PDC step drag drill bits designed for high-performance drilling in soft to medium-hard formations. These bits feature six cutting wings with precision PDC cutters, ensuring efficient penetration, reduced vibration, and long-lasting durability. Ideal for both oil, gas, and geothermal drilling projects.

tooth rotary step drag bits three wings

Our tooth rotary step drag bits with three wings are designed for efficient, precise drilling in metal and hard materials. We offer robust, long-lasting bits that reduce vibration and improve cutting performance. Perfect for industrial applications, they ensure smooth operation, multiple hole sizes, and consistent, accurate results every time.

PDC cutters 3 drag drill bit for mining

Our PDC cutters 3-drag drill bits are engineered for mining applications, providing exceptional durability and penetration in hard rock formations. We offer precision-designed bits that enhance drilling efficiency, reduce wear, and deliver consistent performance. Ideal for demanding mining operations, they ensure longer service life and reliable results in challenging conditions.

PDC tri-wing coreless drag drill bit

Our PDC tri-wing coreless drag drill bits are engineered for efficient rock cutting and drilling. We offer durable, high-performance bits designed to maximize penetration rate and reduce downtime. Ideal for mining and construction applications, these coreless bits provide precision, reliability, and long service life for demanding drilling projects.

custom step drag drill bits with 5 blades

We offer custom step drag drill bits with 5 blades, engineered for precise and efficient cutting in metal, plastic, and other materials. Designed for durability and smooth operation, these drill bits provide consistent performance, long service life, and high accuracy, making them ideal for professional applications and industrial use.

Customize Your Desired Step Drag Bit

Material Selection

We carefully choose the materials for your step drag drill bits based on your application. Whether you need high-speed steel for toughness, cobalt for heat resistance, or carbide for extreme durability, we ensure the material enhances cutting efficiency, longevity, and reliability, matching your specific industrial or professional needs.

Blade Configuration

We customize the number and shape of blades on your step drag drill bits to suit your drilling requirements. With options like 3, 5, or more blades, we optimize cutting speed, reduce vibration, and maintain precision. Each configuration is designed to deliver smooth, clean holes every time.

Coating and Surface Treatment

We apply specialized coatings and surface treatments to improve wear resistance, reduce friction, and extend the service life of your drill bits. Options like titanium nitride or black oxide enhance cutting performance and heat management, ensuring your customized bits remain reliable under heavy use.

Step Size and Taper Design

We tailor the step size and taper design to match the exact hole dimensions you need. By adjusting the increments and taper angle, we provide smooth drilling transitions, minimize material stress, and achieve precise hole diameters, ensuring your drill bits meet your project’s exact specifications.

what are step drag bits?

Step drag bits are a type of fixed cutter drill bit primarily used for drilling in softer geological formations such as clay, sand, and soft shale.

Characterized by their stepped cutting structure with multiple tiers or steps, these bits typically feature two to five wings or blades made of steel with tungsten carbide inserts brazed onto the cutting edges.

As the drill string rotates, these cutting edges shear and scrape away the formation, allowing for relatively fast penetration rates in their intended applications, making them a cost-effective solution for water well drilling, mining exploration, and geotechnical investigations in unconsolidated or lightly consolidated materials。

what are step drag bits made of?

Step drag bits are primarily constructed from high-quality steel alloys that provide the necessary strength and durability to withstand the stresses of drilling. The main body and the wings of the bit are typically forged or cast from these steel alloys, ensuring a robust structure capable of penetrating the target formations. This steel base provides the foundation to which the cutting elements are attached and the threaded connection for the drill string.

The cutting action of step drag bits is achieved through the use of tungsten carbide inserts that are brazed onto the leading edges of the wings. Tungsten carbide is an extremely hard and wear-resistant ceramic material, crucial for effectively shearing and scraping away softer geological materials.

The brazing process securely bonds these carbide inserts to the steel body, allowing them to withstand the abrasive nature of the drilling process.

- Steel Alloy Body: Provides the structural integrity and strength required for drilling.

- Tungsten Carbide Inserts: Serve as the primary cutting elements due to their exceptional hardness and wear resistance.

- Brazing Material: A high-strength alloy, often a copper-based alloy, used to securely attach the tungsten carbide inserts to the steel body.

what are step drag bits used for?

Step drag bits are specifically designed for drilling in softer, unconsolidated, or lightly consolidated geological formations. Their stepped cutting structure and tungsten carbide inserts excel at shearing and scraping away materials like clay, sand, silt, and soft shale.

Due to their efficient cutting action in these less abrasive environments, they are a cost-effective and widely used solution for various shallow to medium-depth drilling applications where high penetration rates are desired without the need for more aggressive or complex drilling tools.

The primary applications for step drag bits include water well drilling, where they are commonly used to create boreholes in aquifers composed of softer sediments. They are also frequently employed in mining exploration for drilling shallow boreholes to assess subsurface mineral deposits in unconsolidated overburden.

Additionally, step drag bits find utility in geotechnical investigations, such as drilling for soil sampling and installing monitoring wells in softer ground conditions. Their relatively simple design and efficient performance in these specific formations make them a practical and economical choice.

- Water Well Drilling: Used to create boreholes in softer formations to access groundwater resources.

- Mining Exploration: Employed for shallow drilling to investigate mineral deposits in unconsolidated overburden.

- Geotechnical Investigations: Utilized for soil sampling and the installation of monitoring wells in softer ground conditions.

- Environmental Drilling: Used for drilling boreholes for environmental monitoring and remediation in suitable geological settings.

step drag bit Types

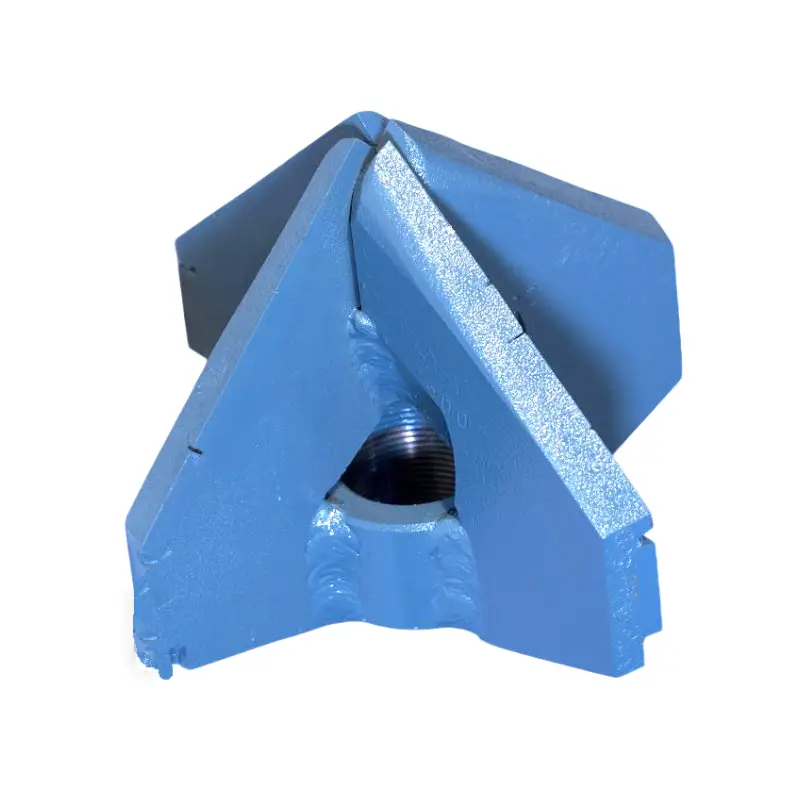

Three-Wing Step Drag Bits

Three-wing step drag bits are a common configuration known for their aggressive cutting action and ability to achieve a high rate of penetration in softer formations. Featuring three distinct cutting wings, each with multiple stepped cutting edges tipped with tungsten carbide, these bits are designed to efficiently shear and remove larger cuttings.

The three-wing design tends to drill faster than four-wing designs in comparable formations but may offer slightly less stability and potentially a rougher borehole. They are widely used in water well drilling and other applications where speed in softer materials is a priority.

Four-Wing Step Drag Bits

Four-wing step drag bits offer enhanced stability and can produce a straighter, more uniform borehole compared to their three-wing counterparts. With four cutting wings, each containing stepped tungsten carbide inserts, these bits distribute the cutting load more evenly.

While potentially having a slightly slower rate of penetration in very soft formations compared to three-wing bits, the four-wing design typically exhibits increased durability and can handle slightly more consolidated materials. They are a preferred choice when borehole straightness and longevity of the bit are important factors in the drilling operation.

Short Step Drag Bits

Short step drag bits are characterized by a shorter overall length and a more compact stepped cutting structure. This design often provides increased rigidity and can be advantageous in specific drilling scenarios, such as drilling in confined spaces or when encountering slightly more variable formations.

The shorter profile can also contribute to improved cutting efficiency in certain soft to medium-soft materials by reducing bit wobble. These bits are available in both three and four-wing configurations to suit different drilling preferences and formation types.

Long Step Drag Bits

Long step drag bits feature an extended overall length and a more gradual stepped cutting structure. This design is often favored for drilling deeper boreholes in consistent, soft formations. The longer profile can help with borehole alignment over greater depths, and the gradual steps can facilitate smoother cutting and better chip evacuation over longer drilling intervals. Like short step drag bits, they are available with varying numbers of wings to optimize performance based on the specific geological conditions and drilling objectives.

why choose our step drag bits?

Step drag drill bits are vital for precision and efficiency in professional applications. Choosing the right supplier ensures durability, performance, and accuracy. Our step drag bits are designed to meet the highest standards, providing consistent results and long-lasting reliability across various materials and industrial needs.

-

Superior Durability: We craft our step drag bits from premium materials to withstand repeated use and high-pressure drilling, ensuring resistance to wear, heat, and deformation, giving professionals confidence in long-term performance for heavy-duty and delicate applications.

-

Precision Cutting: We design our bits for accurate, clean cuts with minimal burrs, optimized blade geometry, and precise step sizes, reducing material stress and maintaining exact hole dimensions for consistent results in metal, plastic, and other industrial materials.

-

Customizable Options: We offer customization including blade number, step size, material, and coatings, allowing clients to get drill bits tailored to their specific project needs, ensuring efficiency, reduced downtime, and optimal performance in all professional drilling tasks.

-

Enhanced Performance: We apply advanced coatings and surface treatments to improve cutting speed, reduce friction, minimize heat buildup, extend bit lifespan, and maintain sharpness longer, ensuring faster, smoother, and more reliable drilling under demanding conditions.

Send Your Inquiry Now

All-in-one Step Drag Bit Solutions for Your Project

Sinodrills provides step drag bit solutions tailored to your specific project needs. Our extensive range encompasses various wing configurations, cutting tip designs, diameters, and connection threads. We offer expert consultation to ensure you select the ideal bit for optimal penetration rates and longevity in your target formations. From water well to geotechnical drilling, rely on Sinodrills for quality, customization, and efficient all-in-one step drag bit solutions.