In the industry filed oil and gas exploration, few components are as critical as the drill string. This marvel of engineering acts as the direct link between the surface drilling rig and the drill bit thousands of feet below ground, enabling the vital process of creating a wellbore. Understanding its intricate design and function is fundamental to successful and safe drilling operations.

This guide will demystify the drill string, breaking down its essential components and explaining how they work in harmony. We’ll explore how this robust assembly transmits power, circulates drilling fluid, and withstands immense forces to continuously penetrate geological formations, bringing energy resources to the surface.

What is a Drill String?

The drill string is the complete assembly of tools and pipes that connects the drilling rig‘s surface equipment to the drill bit at the bottom of the wellbore. Its primary purpose is to transmit rotational power and drilling fluid to the bit, enabling it to cut rock and create a well.

Drill String Components

The drill string is composed of several critical components, each playing a specific role in the drilling process. These components are joined together to form a continuous conduit that extends from the surface rig down to the drill bit.

- Kelly or Top Drive: Provides the rotational power to the entire drill string from the surface.

- Drill Pipe: The main body of the drill string, consisting of numerous sections of steel pipe that transmit torque and circulate drilling fluid. This includes various drill pipe sizes and heavy-weight drill pipe.

- Tool Joints: Thickened, threaded ends of drill pipes that allow individual sections to be securely connected.

- Drill Collars: Heavy, thick-walled steel pipes located just above the drill bit, providing weight-on-bit (WOB) to help the bit cut efficiently and keep the drill string in tension.

- Stabilizers: Components with blades that centralize the drill collars or drill pipe in the wellbore, reducing vibration and maintaining hole gauge.

- Subs (Crossover Subs, Bit Subs, etc.): Short, specialized adapters used to connect components with different thread types or sizes within the drill string.

- Drill Bit: The cutting tool at the very bottom of the drill string that grinds, scrapes, or shears rock to create the wellbore.

How Does a Drill String Work?

The drill string operates as a complex system, transforming power from the surface into effective downhole cutting action. The process begins with either a kelly drive or, more commonly today, a top drive unit on the drilling rig. This unit rotates the entire drill string, transmitting torque down through each section of drill pipe, through the drill collars, and finally to the drill bit. Simultaneously, drilling fluid, or “mud,” is pumped down the hollow center of the drill pipe.

This drilling fluid exits through nozzles in the drill bit, cooling and lubricating it while also flushing rock cuttings away from the cutting face. The fluid then carries these cuttings up the annulus (the space between the drill string and the wellbore walls) back to the surface.

The weight of the drill collars, positioned just above the bit, provides the necessary weight-on-bit (WOB) to enable the drill bit to efficiently break rock, while the drill pipe remains largely in tension, preventing buckling and maintaining stability. This continuous cycle of rotation, fluid circulation, and weight application allows for the progressive extension of the wellbore.

- Rotation: Top drive/Kelly rotates the drill string, transferring torque to the bit.

- Fluid Circulation: Drilling fluid pumped down drill pipe, exits bit nozzles, and returns up the annulus.

- Weight on Bit (WOB): Drill collars provide downward force for cutting efficiency.

- Cutting Removal: Drilling fluid carries rock cuttings to the surface.

- Wellbore Stability: Fluid pressure and pipe tension help maintain wellbore integrity.

Drill String Assembly

The drill string assembly is a meticulous process, connecting various components to form the vital link between the surface rig and the drill bit downhole. This systematic procedure ensures proper functionality and safety for effective drilling operations.

Step 1: Running the Drill Bit and BHA

The process begins with running the drill bit and the Bottom Hole Assembly (BHA) into the wellbore. The BHA, comprised of drill collars, stabilizers, and specialized tools, is carefully assembled first on the rig floor, setting the foundation for the entire drill string.

Step 2: Connecting Drill Pipe Sections

Individual sections of drill pipe, typically 30 or 45 feet long, are then picked up from the pipe racks. Each pipe section is carefully threaded onto the top of the BHA or the previously connected drill pipe, ensuring secure and robust connections to form a continuous column.

Step 3: Lowering and Adding Stands

As sections of drill pipe are connected, the entire drill string is progressively lowered into the wellbore. Once three sections of drill pipe are joined to form a “stand,” this stand is then racked back in the derrick, ready to be added to the string when more depth is required.

Step 4: Circulating Drilling Fluid

Throughout the assembly and drilling process, drilling fluid is continuously pumped down the drill string and returned up the annulus. This circulation is crucial for cooling the bit, lifting rock cuttings to the surface, and maintaining wellbore stability and pressure control.

Step 5: Monitoring and Adapting

The drill string assembly is continuously monitored for optimal performance. Parameters like weight-on-bit, torque, and fluid pressure are closely observed. Adjustments are made as needed to adapt to changing downhole conditions, ensuring efficient penetration and wellbore integrity.

Drill String vs Drill Pipe

Understanding the distinction between a “drill string” and “drill pipe” is fundamental in drilling operations. While often used interchangeably by newcomers, they refer to different, though related, concepts. Here’s a breakdown of their unique roles and characteristics.

What is Drill Pipe?

Recommended Drill Pipes

Drill pipe refers to the individual sections of seamless steel tubing that constitute the majority of the drill string’s length. Each section is typically around 30 feet long and features threaded tool joints at both ends, allowing them to be connected together. Drill pipe’s primary function is to transmit rotational torque and provide a conduit for drilling fluid.

These individual lengths are manufactured to specific API standards, defining their material grade, outer and inner diameters, wall thickness, and connection types. Drill pipe comes in various drill pipe sizes and weights, including heavy-weight drill pipe 4 1/2″ and smaller diameters like 1 2 pipe drill size, chosen based on the well’s depth, drilling conditions, and desired hydraulic performance.

Beyond just drill pipe, the drill string includes critical elements such as the kelly or top drive, drill collars, stabilizers, various subs, and the drill bit itself. It’s the entire functional unit that rotates, pushes, and removes cuttings to create the wellbore.

Components

Drill pipe is a single component – the cylindrical steel tube with tool joints. It’s a building block. Its components are essentially its specific features like material grade, dimensions (OD, ID, wall thickness), and connection design, chosen to meet specific stress and flow requirements.

The drill string, however, is an assembly of multiple distinct components. It includes the drill pipe, but also heavier drill collars for weight, stabilizers for centralization, subs for connections, and the drill bit for cutting. Each part serves a specialized function contributing to the whole system’s operation.

Function

The primary function of drill pipe is to act as a conduit for rotation and fluid flow. It must be strong enough to withstand torsional forces and internal pressure from drilling fluid, while also having the appropriate dimensions for the wellbore and hydraulic efficiency.

The drill string’s function encompasses all aspects of drilling. It is responsible for transmitting mechanical energy from the surface to the bit, applying sufficient weight for rock cutting, circulating drilling fluid to clean the wellbore, and providing a means to lower and retrieve downhole tools.

Handling & Storage

Individual drill pipes are handled and stored in racks on the rig floor or in pipe yards. They are picked up one by one, inspected, and then threaded together to form the drill string, or laid down after being unthreaded. Their handling focuses on preventing damage to threads and pipe body.

The drill string, as a complete assembly, is managed as a single unit during drilling operations. When trips are made, sections of the drill string (typically 90-foot stands, comprising three drill pipes) are racked in the derrick. Its handling involves sophisticated rig equipment designed for heavy, long sections.

Inspection

Inspection of drill pipe focuses on individual joints before they are run into the hole or after they are pulled out. This includes visual inspection, electromagnetic inspection (EMI) for flaws, dimensional checks on the pipe body, and meticulous gauging and visual inspection of tool joint threads. API 5DP dictates many of these requirements.

Inspection of the drill string often refers to the condition of the entire assembly in service or during trips. While individual pipe inspection is part of it, drill string inspection might also involve monitoring vibration, torque, and drag to infer the overall health and performance of the combined components downhole.

Here are the differences between drill pipe and drill string:

| Aspect | Drill Pipe | Drill String |

| Definition | Individual sections of steel tube with tool joints | The complete assembly of all downhole drilling components |

| Components | Pipe body, tool joints, threads | Drill pipe, drill collars, stabilizers, subs, drill bit, etc. |

| Primary Function | Transmit torque, circulate fluid | Transmit power, apply WOB, circulate fluid, create wellbore |

| Handling Unit | Individual joints | Sections (stands) or the entire assembled string |

| Scope of Inspection | Individual joint integrity (body, threads) | Overall performance and condition of the entire assembly |

What is a Drill String Used For?

The drill string is the fundamental assembly used in rotary drilling to create a wellbore. Its primary functions are to transmit rotational energy from the surface to the drill bit, enabling it to cut through rock formations, and to act as a conduit for drilling fluid.

- Transmitting Torque and Rotating the Bit: The drill string effectively transfers the rotational power from the rig’s top drive or rotary table down to the drill bit, causing it to spin and break rock.

- Applying Weight on Bit (WOB): The heavy drill collars at the bottom of the drill string provide the necessary downward force, or weight on bit, to ensure efficient penetration of the rock by the drill bit.

- Circulating Drilling Fluid: It provides the pathway for drilling fluid (mud) to be pumped down to the bit, where it cools and lubricates the cutting elements, and then returns up the annulus, carrying rock cuttings to the surface.

- Guiding the Drill Bit: Stabilizers within the drill string help to centralize the assembly in the wellbore, reducing vibration and ensuring a straighter hole.

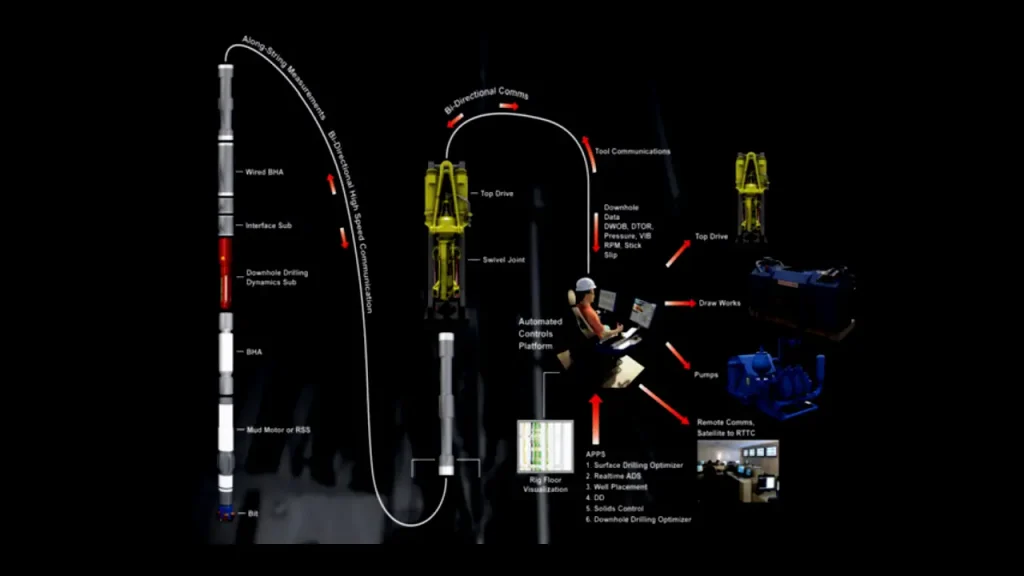

- Allowing for Directional Drilling: Specialized components within the drill string, such as steerable motors and MWD (Measurement While Drilling) tools, enable precise control over the wellbore trajectory for directional and horizontal drilling.

Difference Between Drill String and BHA?

Understanding the distinct roles of the drill string and the Bottom Hole Assembly (BHA) is crucial for effective drilling operations. While the BHA is a vital part of the drill string, it serves a specialized purpose different from the rest of the drill string.

What is the Bottom Hole Assembly (BHA)?

The Bottom Hole Assembly (BHA) is the lower, more specialized section of the drill string, located directly above the drill bit. It comprises a selection of heavier, stiffer, and technologically advanced tools tailored to specific drilling objectives. The BHA’s primary role is to provide weight-on-bit, control wellbore trajectory, provide measurement while drilling (MWD) and logging while drilling (LWD) data, and stabilize the bit during drilling.

Components

The drill string consists of a long column primarily made up of drill pipe sections, along with tool joints and other connecting subs that facilitate its overall length and function. Its components are generally standardized for transmitting torque and fluid.

The BHA, conversely, is a specific collection of heavier and more specialized components. These typically include drill collars, stabilizers, mud motors (for directional drilling), MWD/LWD tools, reamers, and the drill bit itself, all selected to achieve precise drilling objectives.

Primary Function

The drill string’s main function is the global transmission of power and fluid from the surface to the cutting edge, and the removal of cuttings. It acts as the backbone, enabling the entire drilling process by providing the necessary mechanical connection and fluid pathway.

The BHA’s primary function is highly localized to the immediate vicinity of the drill bit. It is engineered to maximize drilling efficiency, control wellbore direction, provide real-time downhole data, and stabilize the drilling assembly for optimal bit performance and hole quality.

Weight Distribution

The drill string’s weight is distributed along its entire length, with the drill pipe comprising the vast majority of this weight. While contributing to overall system tension, the drill pipe’s weight is not primarily used for applying force to the bit.

The BHA is designed to concentrate significant weight directly above the drill bit through the use of heavy drill collars. This concentrated weight is crucial for providing the necessary weight-on-bit (WOB), which drives the drill bit into the formation.

Dynamic Role in Drilling

The drill string’s dynamic role is to continuously rotate and move axially (up and down) as new sections are added or removed, facilitating the overall drilling progress. It must be flexible enough to navigate turns in directional wells while maintaining integrity under torsion and tension.

The BHA’s dynamic role is more focused on direct interaction with the formation. It manages the forces acting on the bit, controls the trajectory through specialized tools, and gathers real-time data about the formation and wellbore, directly influencing drilling optimization and decision-making.

Location in Wellbore

The drill string extends from the surface to the bottom of the well, occupying most of the wellbore’s length at any given time. It is the continuous connection spanning the entire drilled depth.

The BHA is specifically located at the very bottom of the drill string, immediately above the drill bit. It is the part of the string that is always in closest proximity to the active drilling operation.

Conclusion

Understanding the components of the drill string and their collaborative functions is crucial for any successful drilling endeavor. This intricate assembly—from the robust drill pipe and heavy-weight drill pipe to essential drill collars and specialized tools—is the backbone of efficient and safe wellbore creation. Its proper selection, maintenance, and operation directly impact project timelines and costs.

Mastering the mechanics of how the drill string transmits torque, applies weight-on-bit, and circulates drilling fluids is key to optimizing penetration rates and ensuring wellbore stability. Recognizing the critical role each part plays prevents costly failures and enhances overall drilling performance, from shallow wells to complex directional bores.

For reliable, high-quality drill string components that you can trust for your projects, including wholesale drill pipes and heavy-weight drill pipe, choose Sinodrills. We offer a comprehensive range of drill pipe specifications, custom solutions, and unwavering support to meet your drilling needs effectively.