In the world of drilling, selecting the correct tricone bit is paramount to success. The diverse geological formations encountered globally demand a nuanced understanding of bit types to ensure optimal performance, efficiency, and cost-effectiveness. Choosing the wrong bit can lead to slow penetration, premature wear, and costly downtime.

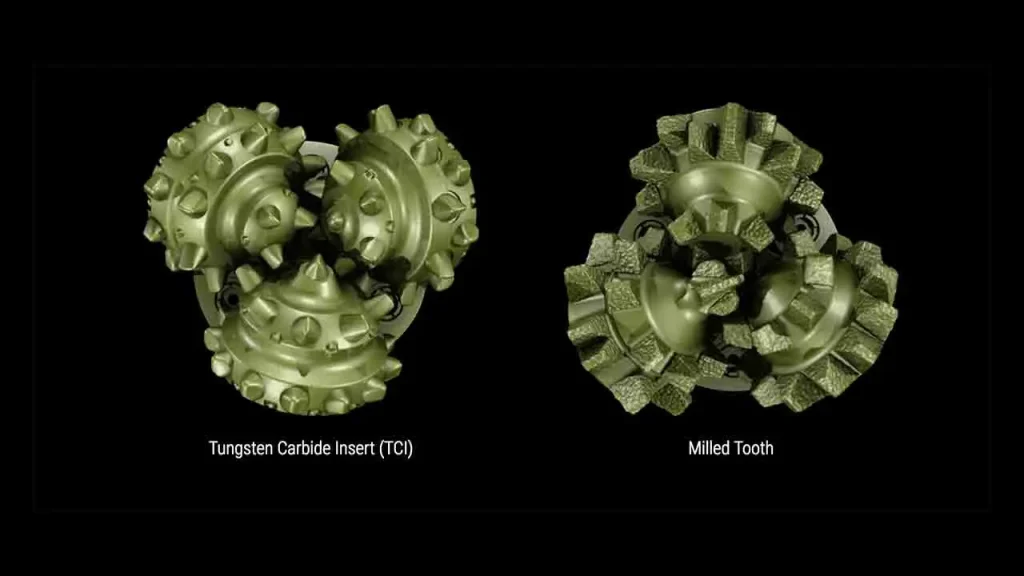

This guide will delve into the various tricone bit types, exploring their unique features and the rock formations they are best suited for. By understanding the distinctions between milled tooth and TCI bits, bearing designs, and other critical aspects, you can make informed decisions to maximize your drilling productivity and achieve superior results on every project.

What is a Tricone Bit?

Recommended Tricone Bits

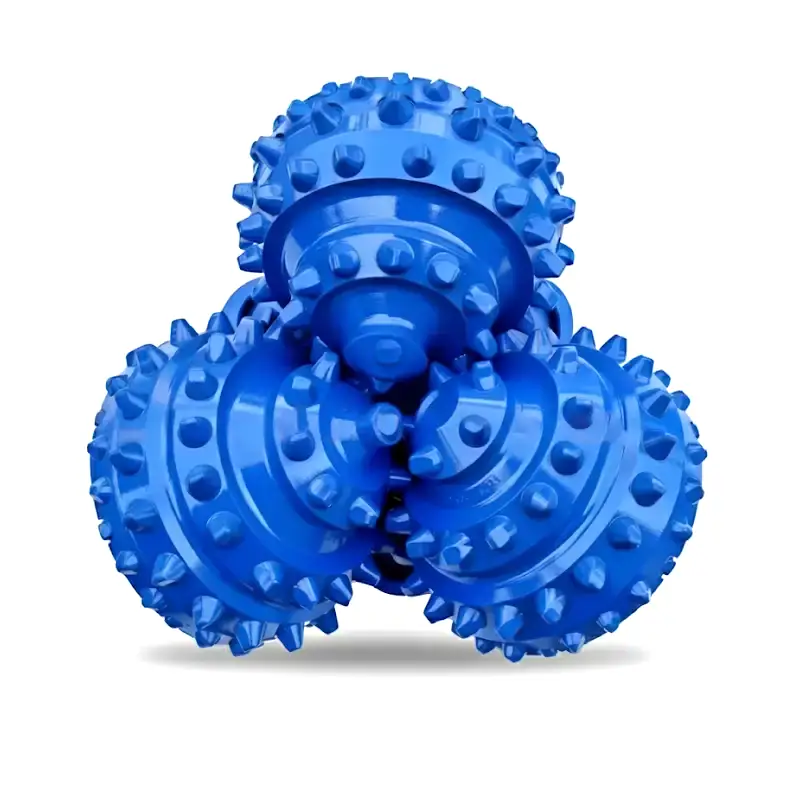

A tricone bit is a type of drill bit widely used in rotary drilling, characterized by its three conical steel bodies that are independently mounted and rotate as the bit turns.

Each cone is typically armed with either milled steel teeth or durable tungsten carbide inserts, which engage the rock at the bottom of the borehole. As the bit rotates, these cones roll and crush, gouge, or shear the rock, effectively breaking it into fragments that are then carried to the surface by drilling fluid.

This design makes tricone bits highly versatile and efficient for drilling through a broad spectrum of geological formations, from soft shales to hard granites.

Tricone Bit Types

Tricone drill bits come in various types, each meticulously designed to optimize drilling performance across different rock formations and operational conditions. Understanding these distinctions is key to selecting the most effective bit for your specific project, ensuring maximum efficiency and bit longevity.

Milled Tooth Tricone Bit

Milled tooth tricone bits feature steel teeth machined directly from the cone’s body. These bits are known for their aggressive cutting action, which involves scraping and gouging the formation.

- Benefits: Their primary benefit lies in achieving high penetration rates in softer, less abrasive formations. The larger, more widely spaced teeth allow for efficient removal of cuttings and prevent bit balling in sticky shales or clays, leading to faster drilling.

- Uses: Milled tooth tricone bits are predominantly used in soft to medium-soft, non-abrasive rock formations such as soft shales, clays, unconsolidated sands, and some limestones. They are ideal for top-hole sections where high ROP is desired.

Tungsten Carbide Insert (TCI) Tricone Bit

TCI tricone bits are equipped with durable tungsten carbide inserts pressed into holes in the bit cones. These inserts come in various shapes and sizes, tailored for different rock types.

- Benefits: TCI bits offer superior wear resistance and extended bit life, especially in hard and abrasive formations. The hardness of the tungsten carbide allows for a crushing and chipping action, providing consistent performance and reducing the need for frequent bit changes.

- Uses: TCI tricone bits are highly versatile and used across a wide spectrum of rock formations, from medium-hard to extremely hard and abrasive rocks. This includes hard limestones, dolomites, granites, quartzites, and basalt, making them suitable for deep drilling and challenging environments.

Sealed Bearing Tricone Bit

Sealed bearing tricone bits incorporate a sealed lubrication system that protects the bit’s internal bearings from drilling fluids and abrasive particles.

- Benefits: The sealed bearing system significantly extends the bit’s operational life by preventing contamination and maintaining proper lubrication. This leads to longer runs, reduced tripping time, and improved overall drilling economics, especially in demanding conditions.

- Uses: Sealed bearing tricone bits are preferred for applications requiring extended drilling intervals, particularly in deep wells, high-temperature environments, or formations with abrasive drilling fluids where bearing integrity is crucial for prolonged performance.

Open Bearing Tricone Bit

Open bearing tricone bits utilize bearings that are exposed to the drilling fluid for lubrication.

- Benefits: These bits are generally more cost-effective due to their simpler bearing design. They are easy to manufacture and maintain, making them a suitable choice for projects with budget constraints or where very long bit runs are not the primary concern.

- Uses: Open bearing tricone bits are typically used in shallower drilling applications, blast hole drilling, or in formations where bearing life is less critical. They are often employed in scenarios where the drilling fluid itself provides sufficient lubrication and cooling for the bearings.

Journal Bearing Tricone Bit

Journal bearing tricone bits feature a robust, friction-based bearing system, often incorporating a floating bushing.

- Benefits: Journal bearings are designed for heavy-duty applications, offering exceptional load-carrying capacity and reliability. Their robust construction allows them to withstand significant weight-on-bit and high rotational speeds, leading to very long bit runs in challenging conditions.

- Uses: Journal bearing tricone bits are primarily used in deep drilling, high-weight-on-bit applications, and very hard, abrasive formations where maximum durability and extended bit life are paramount. They are a staple in oil and gas and geothermal drilling.

PDC Cutter Enhanced Tricone Bit

PDC cutter enhanced tricone bits combine the traditional rolling cone action with fixed Polycrystalline Diamond Compact (PDC) cutters.

- Benefits: This hybrid design leverages the crushing action of the cones and the shearing action of PDC cutters, resulting in improved rate of penetration and enhanced stability in transitional or interbedded formations. It offers a versatile solution for varied rock strengths.

- Uses: These bits are ideal for drilling through formations that exhibit varying hardness or interbedded layers, where a pure roller cone or pure PDC bit might struggle. They are increasingly used in directional drilling and challenging unconventional plays.

Air Drilling Tricone Bit

Air drilling tricone bits are specifically engineered for drilling operations that use compressed air or air/foam as the circulating medium instead of liquid mud.

- Benefits: These bits feature optimized nozzle designs for efficient cuttings evacuation with air, and robust bearing systems capable of handling the higher rotational speeds often associated with air drilling. This leads to faster penetration rates in suitable formations.

- Uses: Air drilling tricone bits are primarily used in formations where water is scarce, where lost circulation is a concern, or where faster penetration rates can be achieved by removing cuttings more efficiently with air, such as in hard, dry rock.

Roller Reamer Tricone Bit

Roller reamer tricone bits integrate reaming elements, typically additional rolling cutters, on the bit’s gauge pads.

- Benefits: The main benefit is the ability to drill and simultaneously ream the borehole to a precise and consistent diameter. This ensures the hole remains in gauge, which is critical for casing installation and maintaining wellbore stability, reducing the need for separate reaming runs.

- Uses: These bits are used in applications where maintaining a precise hole diameter is crucial, especially in unstable formations or when drilling through abrasive sections that tend to wear down the bit’s gauge prematurely.

Extended Nozzle Tricone Bit

Extended nozzle tricone bits feature nozzles that project further down, closer to the bottom of the borehole.

- Benefits: The extended nozzles deliver high-velocity fluid jets directly to the cutting structure and the bottom of the hole, ensuring superior cleaning of the bit face and more efficient removal of cuttings. This prevents bit balling and improves penetration rates.

- Uses: These bits are particularly effective in sticky, reactive, or highly viscous formations where cuttings tend to adhere to the bit face, hindering drilling performance. They are also beneficial in applications requiring maximum hydraulic energy at the bottom of the hole.

Gauge Protected Tricone Bit

Gauge protected tricone bits incorporate additional wear-resistant material, such as tungsten carbide inserts, on the shirttail and gauge pads.

- Benefits: The primary benefit is the enhanced durability of the bit’s gauge, preventing premature wear and maintaining a consistent hole diameter throughout the drilling run. This extends the bit’s service life and reduces the risk of drilling an under-gauge hole.

- Uses: Gauge protected tricone bits are essential for drilling in highly abrasive formations, such as hard sandstones or conglomerates, where the side of the bit is subjected to significant wear. They are also used in directional drilling to maintain hole stability.

Here’s a table showing you the different types of tricone bits:

| Bit Type | Primary Cutting Structure | Key Benefit | Ideal Use Case |

| Milled Tooth Tricone Bit | Steel Teeth | High ROP in soft, non-abrasive formations | Soft shales, clays, unconsolidated sands |

| TCI Tricone Bit | Tungsten Carbide Inserts | Superior wear resistance, extended life | Medium to extremely hard and abrasive rocks |

| Sealed Bearing Tricone Bit | Varies | Extended operational life, reduced tripping | Deep wells, high-temperature, demanding environments |

| Open Bearing Tricone Bit | Varies | Cost-effective | Shallow drilling, blast holes, less critical runs |

| Journal Bearing Tricone Bit | Varies | High load capacity, maximum durability | Deep wells, high WOB, very hard/abrasive formations |

| PDC Enhanced Tricone Bit | TCI + PDC Cutters | Improved ROP and stability in mixed formations | Transitional/interbedded formations |

| Air Drilling Tricone Bit | Varies | Optimized for air/foam drilling, high ROP | Dry, hard rock, lost circulation zones |

| Roller Reamer Tricone Bit | Varies + Reaming Elements | Drills and reams simultaneously, maintains gauge | Unstable formations, precise hole diameter required |

| Extended Nozzle Tricone Bit | Varies | Superior bit cleaning, prevents balling | Sticky, reactive, or highly viscous formations |

| Gauge Protected Tricone Bit | Varies + Carbide/Hardfacing | Maintains hole size, extends gauge life | Highly abrasive formations, directional drilling |

Tricone Bit Functions

The Tricone drill bit is a highly effective tool in rotary drilling, primarily functioning to break rock formations through a combination of crushing, chipping, and scraping. Its design features three independently rotating conical rollers, allowing it to maintain consistent contact with the bottom of the wellbore and adapt to various geological hardness levels from soft soil to hard granite.

- Rock Crushing and Chipping: The three conical rollers spin as the entire bit rotates, causing the teeth (steel milled teeth or tungsten carbide inserts) to alternately impact and press into the rock. This combined crushing and chipping action efficiently pulverizes hard and medium-hard formations into small cuttings for removal.

- Formation Scraping and Tearing: The cones are often slightly offset from the bit’s center line, which introduces a necessary sliding or scraping motion as they roll across the bottom. This shearing effect enhances penetration in softer formations, helping to tear and dislodge the less consolidated rock material quickly.

- Hole Gauge Protection: The outer row of teeth, known as gauge teeth, work to constantly ream and protect the diameter of the newly drilled hole. This ensures the borehole remains the correct size for subsequent casing or tools, maintaining hole integrity and minimizing excessive wear on the bit’s body.

- Bearing and Seal Integrity: Essential internal bearing systems (roller or friction journal bearings) allow the cones to rotate freely, and a seal system protects these bearings from abrasive drilling fluid and cuttings. This sealed lubrication maintains the bit’s mechanical efficiency and extends its lifespan, especially in deep drilling.

How to Choose Suitable Tricone Bits?

Choosing the suitable tricone bit is a critical decision that significantly impacts drilling efficiency, cost, and overall project success. The selection process primarily revolves around understanding the geological conditions and the specific requirements of your drilling operation. Factors like rock hardness, abrasiveness, formation stability, and the presence of interbedded layers all play a crucial role in determining the ideal bit design.

An informed choice involves evaluating various bit features beyond just the size. Consider the type of cutting structure, the bearing system’s durability, the effectiveness of the bit’s hydraulics, and any specialized features like gauge protection. Matching these characteristics to your specific drilling environment will optimize penetration rates, extend bit life, and minimize costly downtime, ensuring a more productive drilling program.

- Rock Formation Type and Hardness: This is the most crucial factor. Soft formations call for aggressive milled tooth bits, while hard, abrasive rocks require durable TCI bits with specific insert geometries.

- Abrasiveness of the Formation: Highly abrasive formations necessitate bits with enhanced gauge protection and more robust cutting structures to prevent premature wear.

- Drilling Fluid Type and Hydraulics: The type of drilling fluid (mud, air, foam) influences nozzle selection and overall bit hydraulics for efficient cuttings removal and cooling.

- Required Bit Life and Cost-Effectiveness: Consider the desired drilling interval. Longer runs in challenging conditions may justify the higher cost of sealed or journal bearing bits.

- Wellbore Stability and Gauge Requirements: If maintaining a precise hole diameter is critical, bits with enhanced gauge protection or reaming features are important.

- Available Weight on Bit (WOB) and RPM: The drilling rig’s capabilities influence the type of bit that can be run effectively; different bits perform optimally under specific WOB and RPM ranges.

Conclusion

Selecting the optimal tricone drill bit is a critical decision that directly impacts drilling efficiency and cost. By carefully considering the formation type, bit design, cutting structure, and bearing system, you can significantly enhance penetration rates, extend bit life, and ultimately achieve more successful and economical drilling operations.

Understanding the nuances between milled tooth and TCI bits, along with the various bearing options and hydraulic configurations, empowers you to make informed choices. This knowledge ensures your drilling program is equipped with the precise tools needed to overcome geological challenges and maximize productivity.

For reliable performance and competitive pricing, consider Sinodrills for your wholesale tricone drill bits. We offer a comprehensive range of high-quality bits designed to meet diverse drilling requirements, ensuring you get the right tool for your specific formation and project needs.