Drilling through soft, unconsolidated ground requires specialized tools, and that’s where the drag bit shines. This simple, fixed-cutter bit is a highly efficient and cost-effective solution for penetrating formations like sand, clay, and soft shale. Understanding its design and mechanics is key to successful and rapid shallow drilling operations.

Drag bit drilling operates through a scraping and chipping action as it is rotated against the formation. Unlike rotary bits that crush the rock, the sharp cutting edges of the drag bit slice away the soft material. This method, often paired with air or mud flushing, quickly clears cuttings from the borehole for fast penetration rates in non-abrasive rock.

What is Drag Bit?

Recommended Drag Bits

The drag drill bit, a type of fixed-cutter drill bit, is a simple, cost-effective tool used for fast drilling in soft, unconsolidated formations like sand, clay, and soft shale. It operates by scraping and chipping the rock face as it rotates, and is frequently employed in shallow geotechnical, water well, and mining exploration projects.

What is Drag in Drilling?

In drilling operations, drag refers to the resistance or friction encountered by the drill string components as they rotate and move within the borehole. This mechanical resistance can be a critical operational concern, impacting drilling efficiency, energy consumption, and the overall stability and health of the drilling equipment and the wellbore itself.

Mechanical Friction: Drag is primarily caused by the physical contact and friction between the drill string (pipe, collars, and bit) and the borehole wall or casing. This force opposes the rotational and vertical movement, demanding increased power from the rig to maintain the desired rate of penetration and rotation, thus increasing operational costs.

Cuttings Buildup: Insufficient removal of drilled cuttings from the borehole can significantly increase drag, as the pipe must rotate through a layer of pulverized rock and debris. This can be particularly problematic in directional or horizontal wells where gravity hinders the transport of cuttings, leading to pipe sticking and torque issues.

Wellbore Geometry: The curvature, ledges, and rough spots along the borehole path create points of high contact, intensifying drag, especially in highly deviated or S-shaped wells. Maintaining a smooth, uniform wellbore is crucial for minimizing this friction, reducing stress on the drill pipe, and facilitating the efficient lowering and retrieval of the drilling assembly.

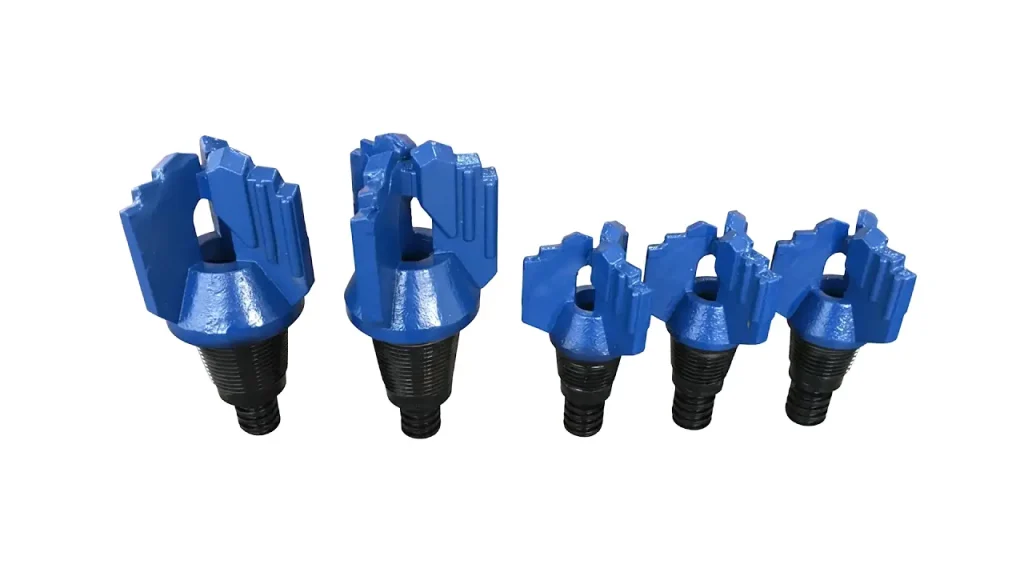

Types of Drag Bits

Drag bits are classified primarily by the number and arrangement of their cutting wings and the type of material they are designed to penetrate. Each distinct configuration optimizes the bit’s performance for specific ground conditions, ranging from highly sticky clays to moderately firm shales, ensuring efficient material removal and penetration rates.

Two-Wing Drag Bits

These bits, often called blade bits or stepped blades, are the simplest design, featuring just two cutting edges. They are best suited for very soft, homogeneous, and unconsolidated formations such as mud, sand, and loose clay. Their large openings allow for excellent fluid circulation and efficient removal of sticky cuttings, minimizing the risk of clogging in adverse conditions.

Three-Wing Drag Bits

Adding a third cutting wing increases the contact area with the formation, offering improved stability and a higher penetration rate than two-wing designs. These bits are more versatile, performing well in soft to medium-hard ground, including packed clay and soft shale. They are a common, economical choice for many shallow water well and geotechnical drilling projects.

Four-Wing Drag Bits

Four-wing designs provide maximum stability and are more aggressive than their two- and three-wing counterparts. The increased number of cutting points allows them to handle slightly harder or more abrasive formations, like moderately firm shales and consolidated soils. The enhanced stability makes them ideal for drilling straighter holes, but they require higher rotational torque.

Stepped Drag Bits

Stepped bits have multiple cutting edges arranged in steps or tiers on each wing, giving the bit a multi-level profile. This design effectively breaks up the formation into smaller cuttings, increasing the rate of penetration in both soft and semi-consolidated ground. They are excellent when transitioning between layers of soft clay and firmer sediments.

How Does Drag Bit Work?

A drag bit operates primarily through a shearing, scraping, and chipping action to remove soft rock and soil. Unlike other bits that crush or hammer, the drag bit’s fixed, sharpened blades are rotated forcefully against the bottom of the borehole. This mechanism makes it highly effective for penetrating unconsolidated or soft sedimentary formations quickly and economically.

- Shearing the Formation: As the drag bit rotates, the sharp cutting wings are forced downward and across the rock face, shearing off the soft material in continuous strips or chips. This action is most efficient in non-abrasive rocks like clay and soft shale, resulting in a high rate of penetration compared to crushing methods in these formations.

- Chipping and Breaking: The rotation and weight-on-bit create a chipping action where the cutter’s edges break the formation at an angle. This is especially true when encountering minor inconsistencies or firmer layers within the soft ground, creating small cuttings that are easily suspended in the drilling fluid and circulated out of the borehole.

- Cuttings Removal: Drilling fluid (air, water, or mud) is pumped through the drill string and out through ports (jets) on the bit face, serving a crucial dual purpose. The high-velocity fluid sweeps the scraped and chipped cuttings away from the bit face and transports them up the annular space to the surface, cooling the bit in the process.

Why Choose Sinodrills Drag Bits?

Choosing Sinodrills drag bits ensures high-quality drilling components designed for maximum performance and longevity in soft ground conditions. Our bits are engineered with superior materials and precision manufacturing, offering exceptional durability and faster penetration rates. We provide cost-effective solutions for all shallow drilling needs, from water wells to geotechnical work.

Superior Material Quality

Sinodrills uses high-grade alloy steel for the bit body and robust tungsten carbide inserts for the cutting edges. This material selection provides exceptional wear resistance and strength, significantly extending the drag bit’s service life, reducing the need for frequent replacement, and lowering overall operating costs.

Optimized Blade Design

Our drag bits feature a geometrically optimized blade and water port design that enhances fluid flow and cutting removal efficiency. This superior configuration prevents bit clogging, especially in sticky formations like clay, ensuring continuous and fast penetration for maximized on-site drilling productivity.

Cost-Effective Wholesale

We provide drag bits directly to customers on a wholesale basis, offering a highly economical solution without compromising on performance or quality. Choosing Sinodrills allows clients to access premium-level drilling tools at competitive prices, significantly improving the cost-per-meter-drilled ratio across multiple projects.

Broad Range of Configurations

Sinodrills offers a comprehensive selection of drag bit types, including two-wing, three-wing, and four-wing designs, tailored for various soft to medium-hard formations. This ensures that customers can select the precise bit configuration to perfectly match their specific ground conditions and drilling requirements.

Conclusion

Drag bit drilling remains a cornerstone of shallow drilling, valued for its simplicity, speed, and exceptional cost-efficiency in soft sedimentary formations. We have explored how its fixed-cutter design effectively scrapes and chips away at materials like clay and sand, offering a distinct advantage over more complex roller cone or hammer systems in these specific geologies.

The continued success of this method depends on selecting the appropriate bit design, such as two-wing or four-wing configurations, to match the exact soil conditions and maintain optimal performance. While they are not suited for hard rock, drag bits are an indispensable and economical tool for geotechnical investigation, water well installation, and certain mining projects.

For all your drilling needs, including high-quality and durable drag bits, trust Sinodrills. We offer a wide selection of wholesale drag drill bits engineered for superior performance and longevity in challenging overburden. Get wholesale drag drill bits from our Sinodrills to enhance your productivity and reduce overall operational costs on your next drilling venture.