The self-drilling anchor system is a versatile ground anchor solution designed to deliver reliable stability across diverse soil and rock formations. Its unique design integrates drilling and anchoring functions, eliminating the need for separate drilling equipment and streamlining installation processes. Widely applied in critical sectors such as soil nailing for slope reinforcement, rock bolting in underground excavations, micro-piling for foundation support, and tunneling, mining, and infrastructure projects, it ensures structural integrity even in challenging geological conditions. By combining efficiency with robust performance, this system enhances construction safety, reduces project timelines, and adapts seamlessly to varying engineering demands, making it indispensable in modern geotechnical engineering.

The self-drilling anchor system is a versatile ground anchor solution designed to deliver reliable stability across diverse soil and rock formations. Its unique design integrates drilling and anchoring functions, eliminating the need for separate drilling equipment and streamlining installation processes. Widely applied in critical sectors such as soil nailing for slope reinforcement, rock bolting in underground excavations, micro-piling for foundation support, and tunneling, mining, and infrastructure projects, it ensures structural integrity even in challenging geological conditions. By combining efficiency with robust performance, this system enhances construction safety, reduces project timelines, and adapts seamlessly to varying engineering demands, making it indispensable in modern geotechnical engineering.

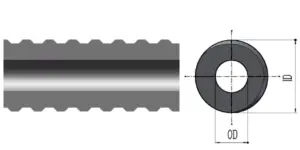

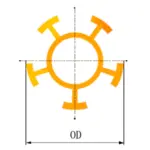

| Size | O.D (mm) | I.D (mm) | Sectional Area (mm²) | Ultimate Load (kN) | Yield Load (kN) | Agt | Weight (kg/meter) | |

| T73 | T73-56 | 73.0 | 56.0 | 1380 | 1035 | 830 | >6% | 10.8 |

| T73-53 | 73.0 | 53.0 | 1780 | 1160 | 970 | >6% | 14.0 | |

| T73-45 | 73.0 | 45.0 | 2230 | 1600 | 1270 | >6% | 17.5 | |

| T73-35 | 73.0 | 35.0 | 2700 | 1865 | 1430 | >6% | 21.2 | |

| Thread direction | Right hand | |||||||

| Thread standard | Internatioanl standard | |||||||

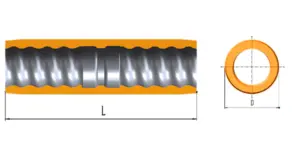

| Thread size | Length(mm) | Out Diameter(mm) | Unit Weight(kg) |

| T73 | 235.0 | 89.0 | 3.7 |

| 245.0 | 95.0 | 3.7 | |

| Steel grade | As per request | ||

| Thread direction | Right hand | ||

| Thread standard | Internatioanl standard | ||

| Hardness (HRC) | HRC25 ~ HRC30 | ||

| Features | All are designed with a middle stop; O rings are available as per request. | ||

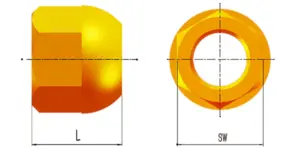

| Size | SW (mm) | L (mm) | Unit Weight (kg) |

| Spherical Nut | |||

| T73 | 95 | 70 | 2.20 |

| Steel grade | As per request | ||

| Thread direction | Right hand | ||

| Thread standard | Internatioanl standard | ||

| Hardness (HRC) | HRC25 ~ HRC30 | ||

| Features | All nuts are machined and with chamfered edges to suit both domed plates and solid plates. | ||

|

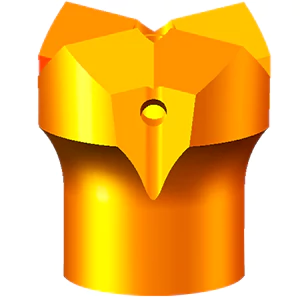

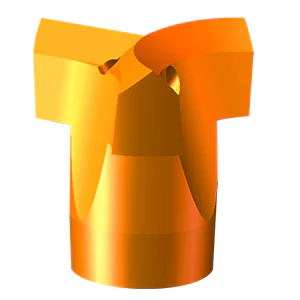

EX | All steel cross bit for loose to medium dense ground formations. |

|

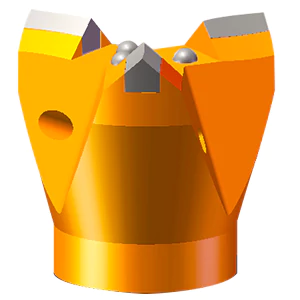

ES | Hardened button bit for weak cemented soil/sands and weak fractured rock formations. |

|

EC | Hardened arch bit for loose to dense soil or sand formations. |

|

EY | Hardened three-cutters bit for weak cemented soil/sand and weak fractured rock formations. |

|

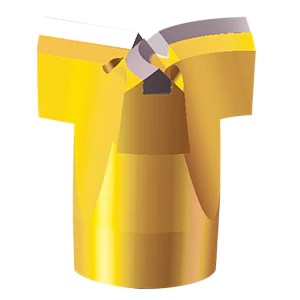

EXX | TC cross bit for medium to strong fractured rock formations. |

|

ESS | TC button bit for strong fractured rock formations. |

|

ECC | TC arch bit for medium fractured rock formations. |

|

EYY | TC three cutters bit for medium fractured rock formations. |

| Bit Matrix | ||||||||||||||

| Dia. | 42 | 51 | 76 | 90 | 100 | 115 | 130 | 150 | 175 | 220 | 250 | 280 | 300 | 350 |

| T73 | √ | √ | √ | √ | ||||||||||

| Thread standard | ISO10208 / ISO 1720 / International standard |

| Thread direction | Left Hand / Right Hand |

| Hardness | HRA87 ~ HRA90 for TC bits, HRC48 ~ HRC55 for all steel bits |

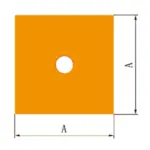

| Size | Solid Plate | ||

| A x A x B (mm) | D (mm) | Weight (kg) | |

| T73 | 250 x 250 x 50 | 80 | 18.0 |

| Note | Other dimensions are available upon request. | ||

| Size | Outside Diameter (mm) | Unit Weight (kg) |

| T73 | 130 | 1.40 |

| Anchor Bolt Size | Anchor Bit Size | Length (mm) | Unit Weight (kg) |

| T73 | T103 | 105 | 3.10 |