Struggling with complex ground conditions for anchoring? Inefficient drilling and separate grouting slow projects down. We offer high-performance Self-Drilling Anchor Bits, the core of an all-in-one system. These sacrificial bits facilitate simultaneous drilling, anchoring, and grouting, dramatically accelerating installation, saving time, and ensuring robust ground support in challenging environments.

Tackling diverse geological formations with self-drilling anchors can be a challenge, with inadequate drill bits leading to inefficient penetration and project delays. Compromised drilling performance wastes time and resources.

We offer high-performance self-drilling anchor bits, precisely engineered to cut and drill through various rock and soil types efficiently. Our bits ensure optimal penetration, enabling your anchors to reach the designed depth swiftly and reliably, ultimately boosting your project’s productivity and success.

Self-Drilling Anchor Bits are crucial for the effectiveness of any self-drilling anchor system, as they are the direct interface with the ground during installation. Designed to drill and allow grout passage simultaneously, their features are optimized for efficiency and performance in diverse geological conditions.

Here are some key features:

Different types of bits are offered for different conditions: To tackle the wide variety of soil and rock formations encountered in construction, a comprehensive range of bit designs is available. Each type is specifically engineered with unique cutting profiles and flushing holes to optimize drilling speed, accuracy, and wear resistance, ensuring optimal performance in anything from loose sands to hard rock.

Primary alloy is applied to manufacture the alloy bit: For maximum durability and cutting efficiency, our alloy bits are manufactured using high-quality primary alloys. This selection ensures superior hardness and abrasion resistance, allowing the bits to withstand the rigorous demands of drilling through abrasive and strong geological formations without premature wear.

Hardened steel bits are the workhorses for softer ground conditions, offering a cost-effective and reliable solution. Their design focuses on efficient penetration and material removal in less abrasive environments.

Tungsten carbide bits are the premium choice for hard, abrasive, and fractured rock. The TC inserts are incredibly hard and durable, allowing the bits to withstand the high impact and wear of rock drilling.

Self-drilling anchor bits, as depicted in the image, are crucial components in various ground engineering applications, enabling efficient simultaneous drilling and grouting. Their specialized designs allow them to penetrate diverse ground conditions while creating the borehole for the anchor.

Here are their key applications:

Pre-supporting: Essential in tunneling and mining, these bits rapidly install temporary or permanent support ahead of excavation. They create immediate stability in unstable ground, enhancing safety and facilitating continuous advance in challenging geological formations.

Micropiling for Foundation Underpinning: Utilized to reinforce existing foundations or create new ones in limited access areas. The bits efficiently drill and grout, extending structural support to competent bearing strata, effectively addressing settlement issues and increasing load-bearing capacity.

Slope Anchorage: Critical for stabilizing unstable natural or excavated slopes. These bits enable the quick installation of anchors that tie back precarious ground, preventing landslides and erosion, thus securing infrastructure and protecting lives.

Retaining Walls: Employed to anchor various types of retaining structures, such as soldier pile walls or secant pile walls. The bits facilitate efficient installation of tie-backs, providing the necessary resistance against lateral earth pressures and ensuring structural stability.

Temporary Works: Widely used for short-term support systems in construction, like excavation shoring or temporary bridge foundations. The rapid installation capability of these bits allows for quick establishment and removal of temporary support, optimizing project timelines.

|

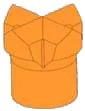

EX

Full steel cross self drilling anchot bit For loose to medium dense ground formations |

|

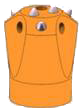

ES

Full steel button self drilling anchor bit For weak cemented soil / sands and weak fractured rock formations |

|

EW

Self drilling anchor clay bit For soft clay and soils |

|

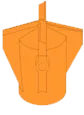

EC

Full steel arch self drilling anchor bit For loose to dense soil or sand formations |

|

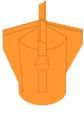

EY

Full steel three cutters self drilling anchor bit For weak cemented soil / sand and weak fractured rock formations |

|

EXX

TC (Tungsten Carbide) cross self drilling anchor bit For medium to strong fractured rock foramtions |

|

ESS

TC (Tungsten Carbide) button self drilling anchor bit For strong fractured rock formations |

|

ECC

TC (Tungsten Carbide) arch self drilling anchor bit For medium fractured rock formatioms |

|

EYY

TC (Tungsten Carbide) three cutters self drilling anchor bit For medium fractured rock faomrations |

| Thread | Bits diameter(mm) | Thread | Bits diameter(mm) |

| R25 | 42mm, 51mm, 76mm | T30 | 42mm, 46mm, 51mm, 76mm, 90mm |

| R32 | 45mm, 51mm, 76mm, 90mm, 100mm, 115mm | T40 | 76mm, 90mm, 100mm, 115mm |

| R38 | 64mm, 76mm, 90mm, 100mm, 110mm, 115mm, 130mm | T52 | 76mm, 90mm, 110mm, 115mm, 130mm, 150mm |

| R51 | 76mm, 90mm, 100mm, 110mm, 115mm, 130mm, 150mm | T73 | 115mm, 130mm, 175mm |

| T76 | 170mm, 220mm | T103 | 175mm, 220mm, 280mm |

| T111 | T127 | 200mm, 220mm |